Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Why need convert platic to oil?

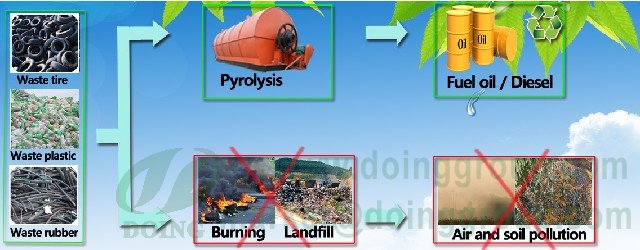

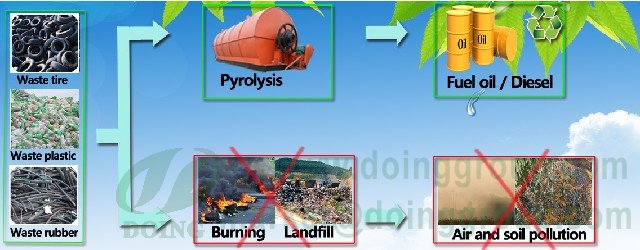

Nowadays, more and more waste plastics generated everyday, It brings pollutions to environment and the world became worse. Some people suggest burning them, but it will cause" withe pollution". Many year past. With our advanced technology, Henan Doing Mechanical Equipment Co., Ltd reserched a new way to diposal waste plastic, Do you know why we need convert platic to oil? Here have four points:

1. It stimulates local economies and strengthens communities.

2. it’s an alternative energy investment that makes sense.

3. it’s an innovation that redefines recycling for a greener future.

4. It creates partnerships for sustainable energy production.

Different plastic type

DOING waste plastic to oil machine can pyrolysis different plastic sizes, for both industrial and home uses, can easily transform a kilogram of plastic waste into a liter of oil with plastic pyrolysis process, using about 1 kW•h of electricity but without emitting CO2 in the process. Waste pyrolysis of plastic to oil machine uses a temperature controlling electric heater instead of flames, pyrolysis processing anything from polyethylene or polystyrene to polypropylene.

Many think that this type of recycling is not a solution, but that instead the world should be seriously focused on the first “R” — which is reducing. We should shun single-use plastic (such as your average PET bottle or disposable container) altogether, they argue. The world’s oil resources are diminishing; does technology like this enable our denial of that fact, or is it a hopeful and constructive step in the right direction?

The way to convert plastic to oil

1. It stimulates local economies and strengthens communities.

2. it’s an alternative energy investment that makes sense.

3. it’s an innovation that redefines recycling for a greener future.

4. It creates partnerships for sustainable energy production.

Different plastic type

Many think that this type of recycling is not a solution, but that instead the world should be seriously focused on the first “R” — which is reducing. We should shun single-use plastic (such as your average PET bottle or disposable container) altogether, they argue. The world’s oil resources are diminishing; does technology like this enable our denial of that fact, or is it a hopeful and constructive step in the right direction?

The way to convert plastic to oil

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.