Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Furnace oil from plastic waste?

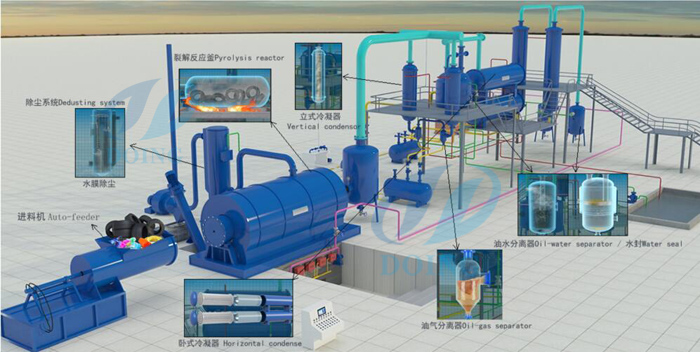

Plastic waste to furnace oil machine

Furnace oil from plastic waste machine

1.Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre/plastic will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get crude oil, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius, After all these steps, you can start another batch.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.