Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

Process of recycling plastic pyrolysis plant

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Process of recycling plastic pyrolysis plant

Process of recycling plastic pyrolysis plant

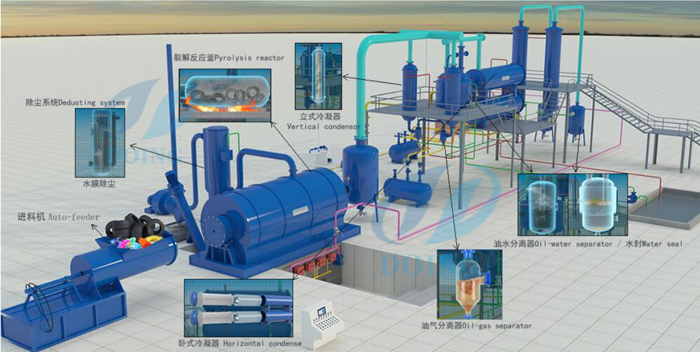

Process of recycling plastic pyrolysis plant is a machine that can recycling process waste plastic to usefuel plastic oil and carbon black.

Process of recycling plastic pyrolysis plant

Process of recycling plastic pyrolysis plant

Plastic recycling is the process of recovering different types of plastic material in order to reprocess them into varied other products, unlike their original form. Plastic recycling refers to the process of recovering waste or scrap plastic and reprocessing it into useful product.

Plastic recycling not only promotes proper utilization of plastic waste but also helps conserve the environment, making it cleaner and greener.

Process of recycling plastic pyrolysis plant working process:

Process of recycling plastic pyrolysis plant working process

Process of recycling plastic pyrolysis plant working process

1.Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil.

Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre/plastic will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank.

Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get crude oil, the temperature will be low, at this time, carbon black will be discharged automatically.

5. when the temperature falls to 100 degree Celsius, After all these steps, you can start another batch.

Process of recycling plastic pyrolysis plant raw material and final product

Process of recycling plastic pyrolysis plant raw material and final product

When the whole process is over, we can get fuel oil, steel wire, carbon black from process of recycling plastic pyrolysis plant . And they all have a wide range of applications.

More specific application are as follows:

Fuel oil application

Fuel oil application

1.Fuel oil :Fuel oil is widely used in marine boiler fuels, furnace fuels, metallurgical furnaces and other industrial furnace fuels. Depending on the application, fuel oil can be classified into marine fuel oil and furnace fuel oil and other fuel oils. According to the statistics of the National Bureau of Statistics, China's fuel oil consumption is mainly concentrated in power generation, transportation, metallurgy, chemical, light industry and other industries.

Carbon black application

Carbon black application

2.Carbon black:Carbon black is used for briquetting for burning and refining.And the refining can be used for making new tire,shoe soles,paint.

Whole process of recycling plastic pyrolysis plant with out any air pollution, this waste plastic pyrolysis plant not only can recycling the waste plastic harassed us in the dailylife,but also can bring us huge profits!More detail in formation ,feel free to contact us!

Request a Quote for the Process of recycling plastic pyrolysis plant

Please leave your contact information and Process of recycling plastic pyrolysis plant requirements so that our professional team can contact you as soon as possible.