Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

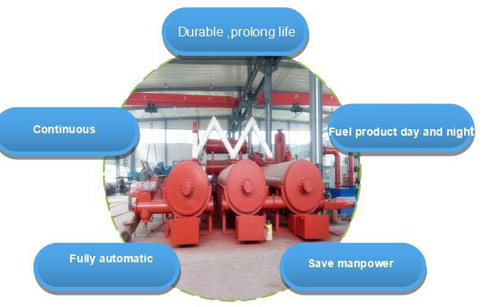

Advantages of continuous waste tire pyrolysis plant

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Continuous waste tire pyrolysis plant

As the vehicle increasing with the improving living standard, more and more waste tires generated every day. And waste tires as a solid waste not only occupy the land, the most important is it cause pollution to the environment. So how to dispose the waste tires becoming more and more necessary. That’s why we developed the waste tire pyrolysis plant.

Continuous waste tire pyrolysis plant

Advantage of continuous waste tire pyrolysis plant

1.High capacity, which can process at least 10 tons waste tires per day, up to 100 tons waste tires per day;

2.Fully automatic with continuous feeding and discharge system;

3.PLC or computer control system, thus to save labour;

4.Multiple reactors design for fully pyrolysis to get high oil rate;

5.Indirect heating to prolong the usage life of the reactor;

6.Same as the batch type waste tire recycling linet, it’s also applicable to process waste plastics.

If you want to know more informations about our continuous fully continuous waste tire recycling line, please feel free to contact us. We DONG Company has specialized in waste tire pyrolysis project for about 8 years, we would like to provide valuable informations and suggestions to help you implement this project.

Final product of application of advantages of continuous waste tire pyrolysis plant

Fuel oil application

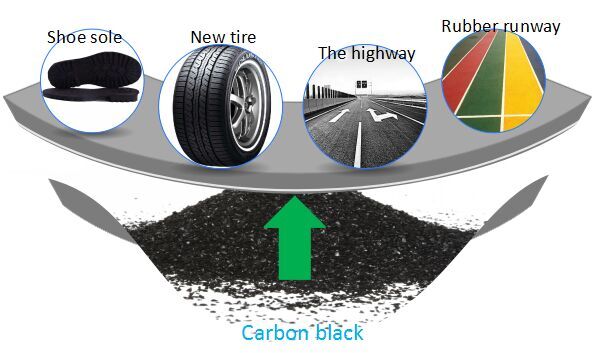

Carbon Black

Carbon black application

Request a Quote for the Advantages of continuous waste tire pyrolysis plant

Please leave your contact information and Advantages of continuous waste tire pyrolysis plant requirements so that our professional team can contact you as soon as possible.