Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

FAQ

- 11-11

What's pyrolysis technology?

- 08-15

What is waste oil recycling plant? How does it work?

- 04-27

What's the TDF(tire derived fuel )oil quality of waste tire pyrolysis plant?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

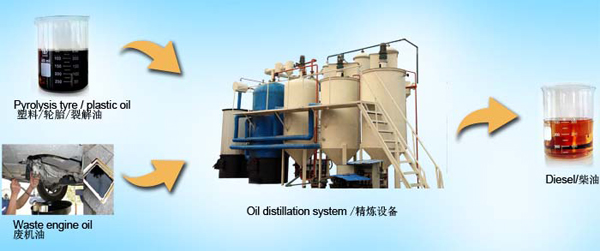

Oil distillation machine

We provide free trial service.

You can also visit our factory.

- Tel: +86-13526692320

- WhatsApp: +86-13526692320

- Phone: +86-37156771821

- Email: sales@doinggroup.com

Oil distillation machine

Oil distillation machine advantages

Indirect heating can protect reactor, which makes no pollutions and greatly increase the service life of oil distillation machine.

2.Better oil quality

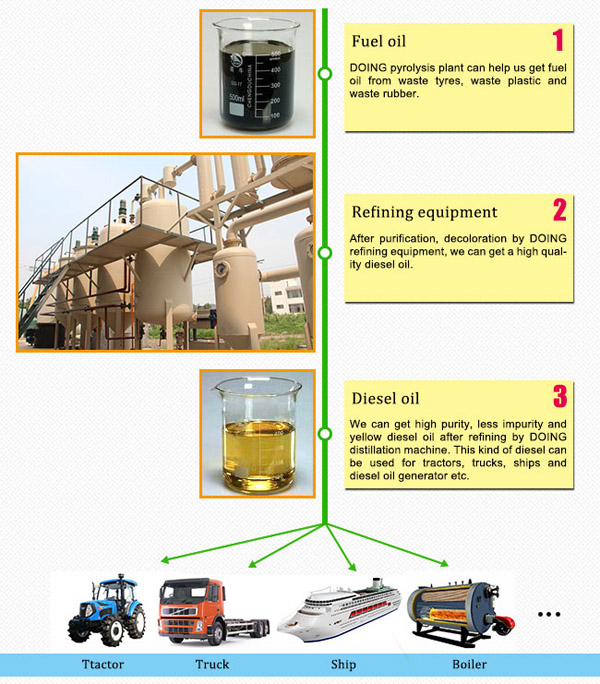

After oil distillation machine, we will add some chemical to remove color and odor in the diesel, so as to improve the diesel quality.

The diesel from our oil distillation machine can be used in diesel generator, tractors, trucks etc.

3.Continuous working

When operate oil distillation machine first you pump oil inside the reactor to heat. After finished heating, it will become oil gas and goes to cooling system.

Then start another tank. So, the first reactor is empty, no need to stop, you could pump another tank of oil again into the first tank, continuously working.

4.High oil yield.

The raw material for our oil distillation machine can be tire oil, plastic oil or waste oil. After processed by our Plastic to oil distillation machine you can get 85% diesel and the remaining will be bitumen.

The main working flow of DOING's oil distillation machine are as follows:

DOING oil distillation machien working process

2. High temperature distillation of the base of the reactor to separate some of the residue from the heavy oil. The resulting light oil and gas will enter the next system.

3. Light oil and gas will be liquefied through the condensing system and flow into the tank.

4. The liquefied light oil obtained is subjected to a degreasing and desulfurization treatment, and finally, a clean and transparent non-standard diesel oil is obtained.

Through oil distillation machine process we can finally get diesel and asphalt. Due to its wide range of uses in the market, huge profits can be obtained after sales. The specific profit analysis is as follows:

Operating costs

Waste oil: 10 tons X288 US dollars / ton = 2868 US dollars

Heating the fuel can use any of the following:

1) Coal: 0.4 tons X 64 dollars/ton = 25 dollars

2) Fuel: 0.6 tons x 478 dollars/ton = 287 dollars

3) Diesel: 0.5 ton X 765 U.S. dollars/ton = 382 U.S. dollars

4) Natural gas: 200m23 X 0.36USD / m3 = 72USD

Power consumption: 25KW / h X 0.16USD X 20h = 80h

Water consumption: water resources can be recycled, almost no consumption

Workers: 1-2 people X 16 dollars = 32 dollars

Earnings/day

Fuel: 8 tons X 765 dollars/ton = 6118 dollars

Asphalt: 1.5 tons X 175USD/ton = 263 dollars

Profit/day (calculated on fuel diesel) $3017

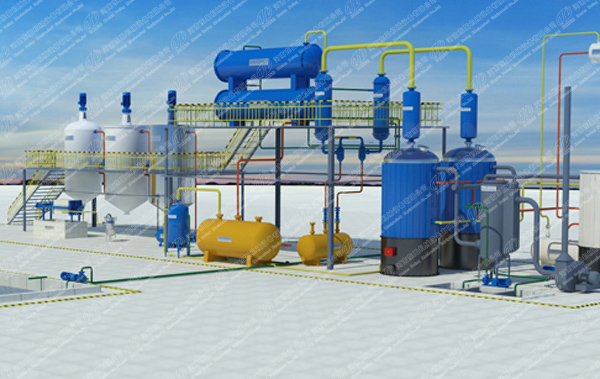

Our oil distillation machine main advantages are as follows:

DOING 3D oil distillation machine

1. Spiral coil heating makes the heating more uniform.

2. Double heating system, fast heating, short time.

3. Vertical reactor design to facilitate slagging.

4. Semi-continuous equipment, simple operation, moderate investment.

Request a Quote for the Oil distillation machine

Please leave your contact information and Oil distillation machine requirements so that our professional team can contact you as soon as possible.