Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

How to convert of plastic waste to fuel oil ?

Conversion of plastic waste to fuel oil machine

Conversion of plastic waste to fuel oil machine

Conversion of plastic waste to fuel oil ?

Conversion of plastic waste to fuel oil working process

1.Put raw material into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feeding machine is closed.

2.Reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃ (250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied into oil and stored in the oil tank. The incondensable gas through dusulphuration and dedusting by hydroseal will be led to the furnace for recycling.

3. After all the above work has been done, cool down the reactor. Then the carbon black will be discharged automatically.

4.There possibly will be a little exhaust gas left, and you should not expel it until it has reached the emission standard.

5.Before starting next batch, make sure all the work has been done.

45% plastic oil

Plastic fuel oil uses

2. Used as heating material.

3. Sell it into oil refining factory to further process it.

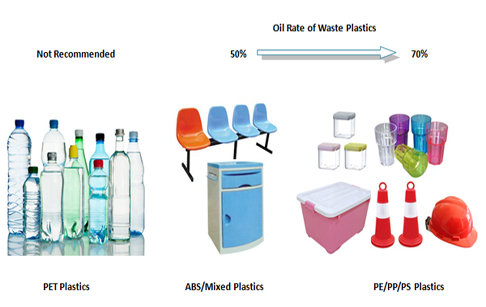

As concerned above ,Conversion of plastic waste to fuel oil can handle different kinds of waste plastic.Some people may wonder ,after the different waste plastic were dealed ,the final oil yield is same?Of course not same!Different waste plastic can get different amount of fuel oil.We have sum up with different kinds of waste plastic oil yield for your reference.

Different kinds waste plastic oil yield

Pure PP plastics 90%

Pure PS plastics 90%

Pure ABS plastics 40%

Pure white plastics sheets 70%

Instant noodles packing bags 40%

Plastics logo 20%

Paper-mill wastes Dry 60% Wet 15-20%

Plastic household garbage 30-50%

Pure plastic cable sheath 80%

Pure plastic bags 30%

PVC/PET Not suitable

What is the specific waste plastic you want to handle with our waste plastic pyrolysis plant? The specific oil rate can consult us at any time!

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.