Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

What does distillation of crude oil produce?

Crude oil distillation

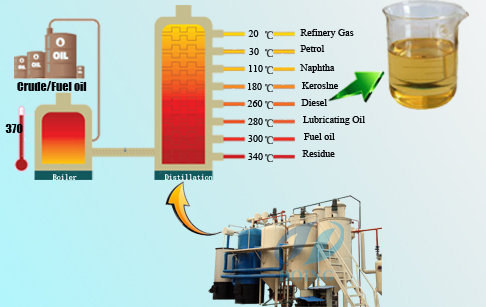

Distillation of crude oil is the process of converting crude oil into a useful product. Crude oil consists of hundreds of different hydrocarbon molecules and is separated by a refining process. The process is divided into three basic steps: separation, conversion and processing.

Crude oil distillation machine working process

Separation refers to the distillation process. Crude oil is heated in the furnace so that hydrocarbons can be separated by their boiling point. In the reactor, the heated petroleum vapor is divided into parts according to weight and boiling point. The lightest fraction, including gasoline, rises to the top of the tower before it condenses back into liquid. The heaviest parts will settle at the bottom because they will coagulate in advance.

Convert

Conversion is simply the process of converting a hydrocarbon species to another hydrocarbon. Among them, the required product is gasoline. Cracking is the process of converting a heavier, less valuable crude oil fraction into a lighter product. Cracking uses heat and pressure to break down heavier elements into lighter elements. Alkylation is another common process that is essentially the opposite of cracking. During alkylation, small gaseous byproducts combine to form larger hydrocarbons.

Deal with

Processing is the final process of refining, including the combination of processed products to create various octane ratings, vapor pressure performance, and the special properties of products used in extreme environments. A common example of treatment is the removal of sulfur from diesel fuel, which is necessary to meet the clean air guidelines. Strong processing technology is the most time-consuming refining step.

Through this process, 80-85% of diesel fuel and 15-20% of asphalt can be obtained. Their specific uses in life are as follows:

Diesel oil application

The DoingGroup's crude oil distillation equipment has the following advantages:

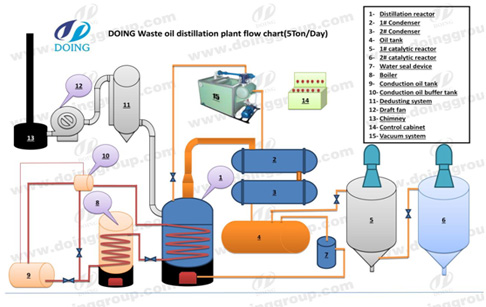

DoingGroup's crude oil distillation machine

2. Double heating system, heating speed, save time, improve efficiency.

3. Cooling type is circulating water cooling, and the entire process hardly consumes.

4. The type of equipment is a semi-continuous machine with moderate investment and easy operation.

5. Only 2 workers are required for each class, saving manpower expenses.

6. Customers can customize small model trial production equipment according to individual needs and capital requirements.

If you have recent investment needs in this area and want to learn more about the equipment, please click this link!

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.