Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

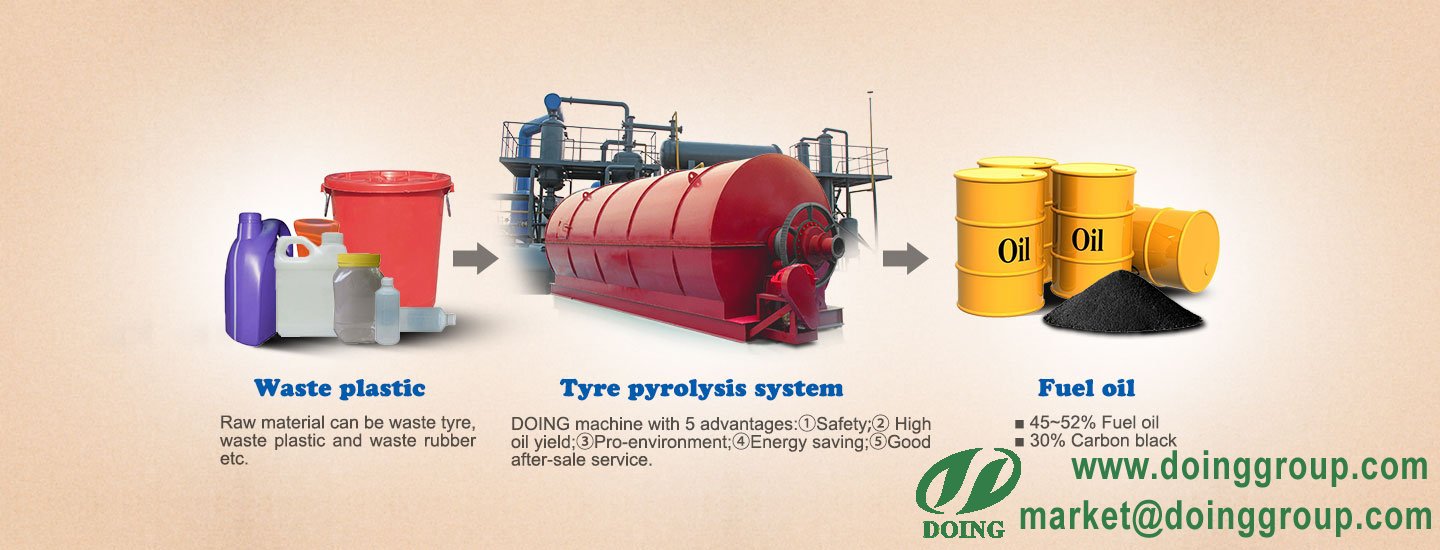

Pyrolysis of waste plastics

Direct recycling of waste plastics is not always possible, e.g. waste plastics can be contaminated; moreover, they often mixed with different sorts of materials such as paper, glass, metal, biowaste, etc. Food and beverage packaging is a typical example when plastic attached to other materials (aluminium/polymer laminate). It is impossible to separate this laminate from paper at the recycling facility.

Incinerators do not "welcome" large amount of plastics in the waste due to large quantity of the released heat as well as non-complete burning of plastics and associated with it clogging the equipment.

Waste plastic pyrolysis

Pyrolysis of plastics can be used to dispose the waste and to recover synthetic fuel. Pyrolysis oil recovered from the process can be used as diesel generator fuel or fuel for burners.

After pyrolysis in the kiln at ~400 C the pyrolysis gases are cooled down. The recovered oil is fed into the distillation column and separated into three fractions; light oil from the top, medium oil from the middle and heavy oil from the bottom of the column. These three types of oils are stored in separate oil tanks and sent to the furnaces and cogeneration system in the plant as fuel through piping, or loaded onto a tank lorry for shipment to customers.

Incinerators do not "welcome" large amount of plastics in the waste due to large quantity of the released heat as well as non-complete burning of plastics and associated with it clogging the equipment.

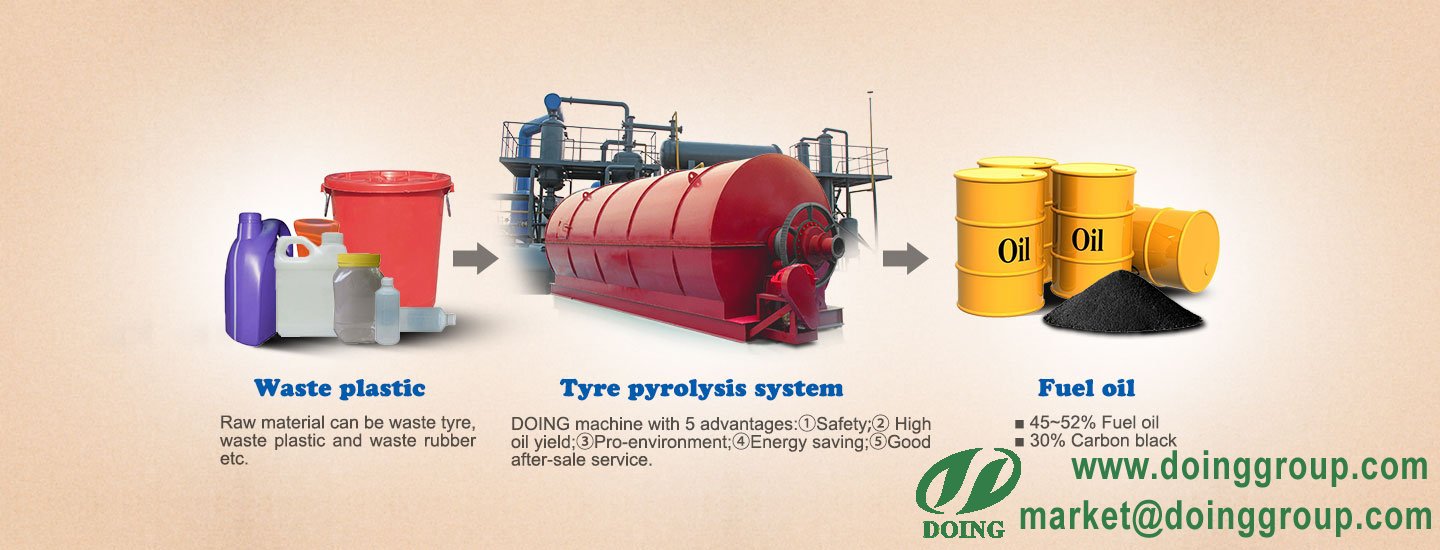

Waste plastic pyrolysis

Pyrolysis of plastics can be used to dispose the waste and to recover synthetic fuel. Pyrolysis oil recovered from the process can be used as diesel generator fuel or fuel for burners.

After pyrolysis in the kiln at ~400 C the pyrolysis gases are cooled down. The recovered oil is fed into the distillation column and separated into three fractions; light oil from the top, medium oil from the middle and heavy oil from the bottom of the column. These three types of oils are stored in separate oil tanks and sent to the furnaces and cogeneration system in the plant as fuel through piping, or loaded onto a tank lorry for shipment to customers.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.