Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

Automatic waste plastic to oil recycling plant

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Automatic waste plastic to oil recycling plant

Main devices contains in automatic waste plastic to oil recycling plant

1. Feedstock pretreatment system 2. Fast feeding system 3. pyrolysis reactor 4.Buffer chamber 5.Vertical condensers1 6. vertical condensers2 7. Oil gas separator1 8.Oil gas separator2 9. Oil tank1 10.Oil water separator 10. Horenzental condensers1 11. horenzental condensers2 12.Water seal device1 13. Water seal device2 14. Vaccuum system 15.Odor removal tank 16. Dedusting device 17. Draft fan 18. Chimney

automatic waste plastic to oil recycling plant

Pyrolysis process:

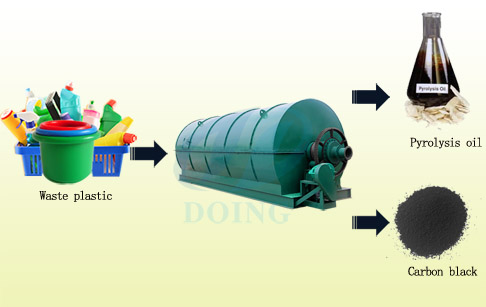

The technology and operation of automatic waste plastic to oil recycling plant are easy and safe.The whole working process is in normal pressure,the raw material no need to be washed firstly,it can be put into the reactor for pyrolysis directly, and then heating, catalyzing,pyrolysis and cooling into fuel oil.

Features of Automatic waste plastic to oil recycling plant

1.Our Automatic waste plastic to oil recycling plant can be environment friendly

2.Automatic waste plastic to oil recycling plant is Full open door design

3. Fully enclosed carbon black discharging system under high temperature

4.Energy conservation and low cost on operation

5.Raw material is very cheap and easy to available

6.The process can applied to all soft plastic based material

Advantages of Automatic waste plastic to oil recycling plant

Our Automatic waste plastic to oil recycling plant is very long service life

Required less covering area

Our plastic recycling plant is eco-friendly

Highly oil yield

More convenient method for carbon black discharge

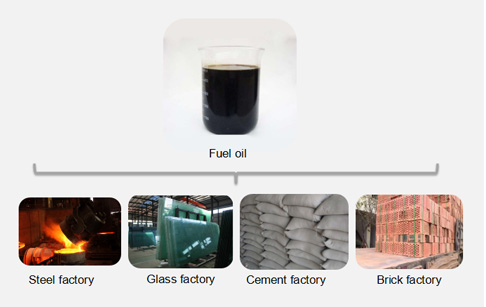

FUEL OIL (40 to 45%)

Fuel oil application

CARBON BLACK (30 to 35%)

Carbon black application

Carbon black produced by plastic pyrolysis application (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed :

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Request a Quote for the Automatic waste plastic to oil recycling plant

Please leave your contact information and Automatic waste plastic to oil recycling plant requirements so that our professional team can contact you as soon as possible.