Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

FAQ

Waste oil distillation machine

We provide free trial service.

You can also visit our factory.

- Tel: +86-13526692320

- WhatsApp: +86-13526692320

- Phone: +86-37156771821

- Email: sales@doinggroup.com

Waste oil distillation machine

Series waste oil distillation machine is special for treating the black waste oil, including waste engine oil, gear oil, dirty diesel oil, mixed oils ,tyre oil,plastic oil etc. The main working process of DY waste oil distillation machine is high temperature heating distillation, making waste oil from liquid states to gas states. After pyrolysis, the waste oil is changed to clean diesel fuel. DY waste oil distillation machine can effectively remove the wear debris, asphalt, wax quality, impurities, moisture, acid quality, organic acids and inorganic acids from oil, also it can get rid of the carbon particles, deep oxides and other fine impurities which disperse in oil. DY waste oil distillation machine is very suitable for the oil refinery company, also for the small oil company who want to make the oil by self.

Waste oil distillation machine is energy-saving, environment friendly machine, during the process it just generates less waste (sludge), the waste (Sludge) doesn’t contains any oil, so it is no pollution for the environment (The waste/sludge also can be processed into a carbon toner for printing the raw materials); during the oil regenerating process, the oil-gas and low volatile are discharged after combustion of hydrocarbons and purification treatment, so, there is no odor and no environment pollution.

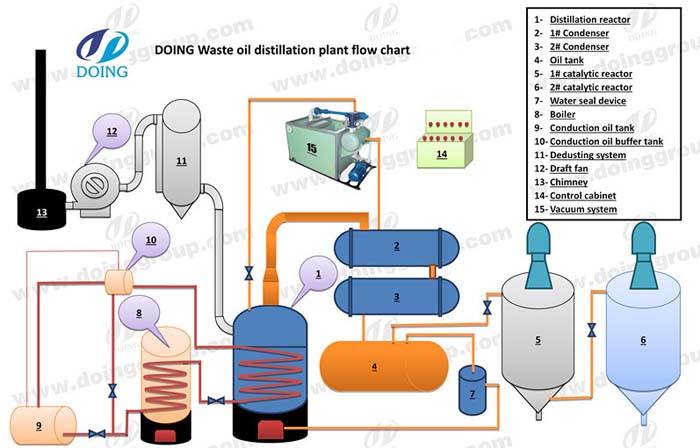

Waste oil distillation machine wokring process

Waste oil distillation machine process

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

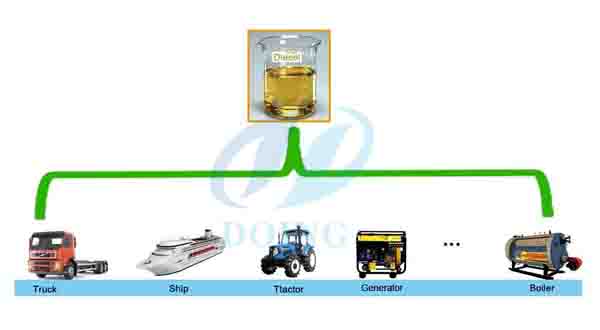

Waste oil distillation machine diesel application

The final diesel after refining can be used for tractors, trucks, ships and diesel oil generators etc.

Diesel application

Request a Quote for the Waste oil distillation machine

Please leave your contact information and Waste oil distillation machine requirements so that our professional team can contact you as soon as possible.