Oil Extraction Plant Using Waste Tyres

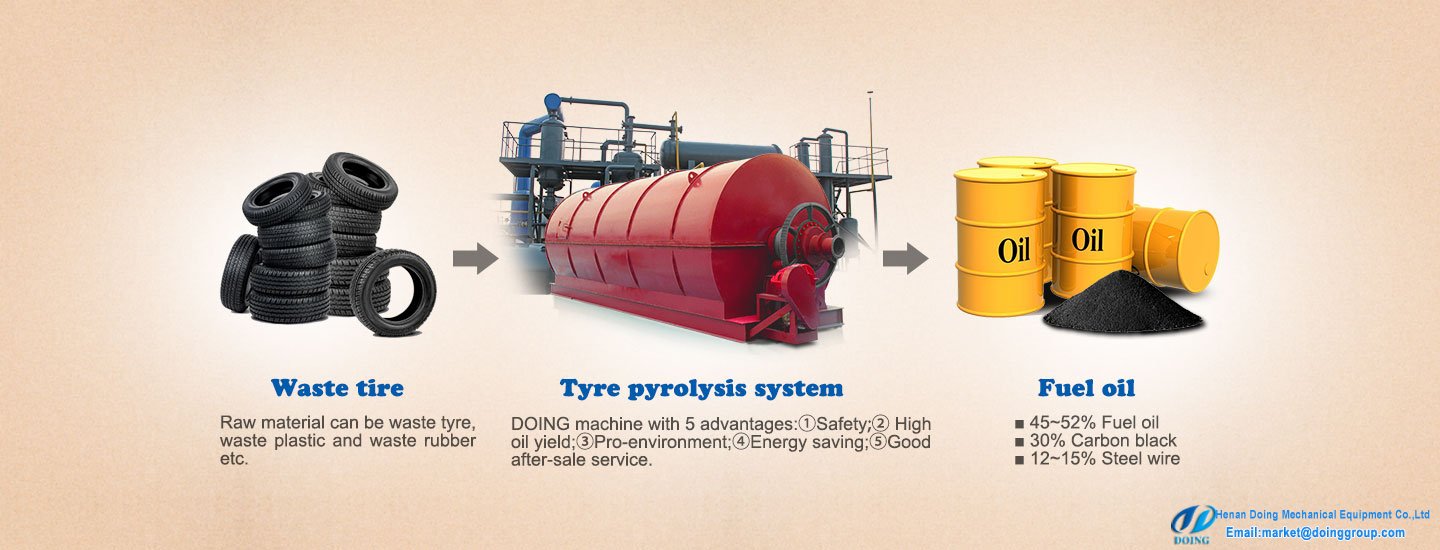

DOING GROUP is a renewable energy manufacturer, specializing in providing Oil Extraction Plant Using Waste Tyres,waste recycling plant and technology transfer for waste tyre/rubber/plastic(PP, PE etc. ), landfill and municipal waste to reclaim fuel oil, carbon black and steel wires from the low investment and running cost process. Our proprietary technical process of cracking(pyrolysis) the waste tyre/rubber/plastic(PP, PE etc. ) is remarkably superior to satisfy the growing demand for fuel and energy.

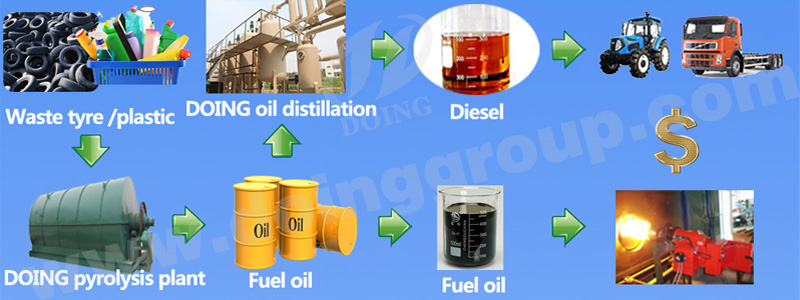

disposal tyre to (energy)fuel oil

Oil Extraction Plant Using Waste Tyres mainly involves in recovering the hydrocarbons(fuel oil) and other components present in the waste tyre/rubber/plastic(PP, PE etc. ) using a proprietary catalyst under controlled temperature and pressure. These tyre/rubber/plastic(PP, PE etc. ) recycling machinery is available at industrial leading price.

waste engine oil to diesel

a> Environment friendly, no pollution and low investment budget.

b> Reclaimed product: 40%-45% fuel oil, 30%-33% carbon black powder(5mesh around), 10%-15%steel wire, 10% Combustible Gases.

c> The Fuel oil which is a substitute for Light Diesel Oil or Furnace Oil.

d> The Combustible Gases are used back for reheating there by reducing the energy costs.

e> The Carbon Black can be used to manufacture further value-added products that have higher market value and demand.

f> The Steel extracted fetches good value in the market.

g> The products generated by us have been scientifically tested by several labs with excellent results(SGS oil report) and terrific feedback by our clients.

h> The process developed is a 100% emission free system, thus making the world more cleaner and greener.

i> Capacity: 5t/day, 8t/day, 10t/day.

j> You investment will be recovered in 2-4 months! ! !

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating oil extraction plant using waste tyres;no waste emission.

- 4.Auto welding to ensure oil extraction plant using waste tyres life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do oil extraction plant using waste tyres project plan,including financial analysis.

Help customer finished oil extraction plant using waste tyres delivery,foundation,installation,trainning,commissioning and try running.

One year warranty period .

PREV: Waste plastic to energy machine

NEXT: Tyre to Oil

If you are intrested in investment oil extraction plant using waste tyres ,or any other questions,such as project report,project cost,you can leave a message in below form, we will back to you once we got your message.

Leave a inquiry for oil extraction plant using waste tyres: