Continuous waste tire to fuel oil pyrolysis plant

Continuous waste tire to fuel oil pyrolysis plant

Continuous waste tire to fuel oil pyrolysis plant

For continuous waste tire to fuel oil pyrolysis plant, its raw material can be waste tires, plastic and other rubber. If your raw material is waste tire ,you can get fuel oil, carbon black and steel wire after pyrolysis processing.

Continuous waste tire to fuel oil pyrolysis plant raw material

The raw material of continuous waste tire to fuel oil pyrolysis plant

2.Waste plastic

3.Waste rubber

Continuous waste tire to fuel oil pyrolysis plant final product and application

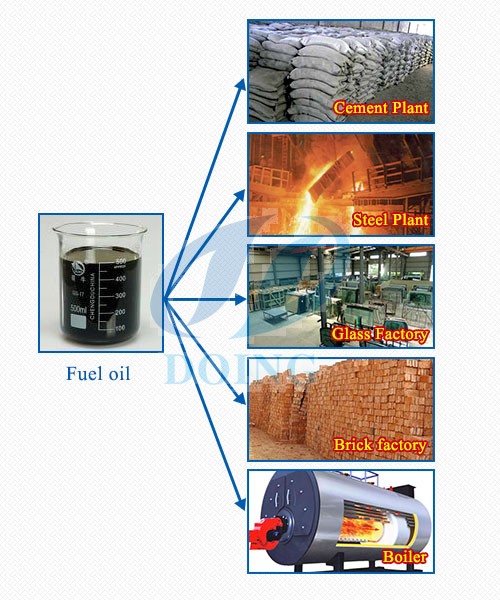

The main product-fuel oil produced by our continuous waste tire to fuel oil pyrolysis plant is widely used for industrial and commercial purposes.

With the heating value 10592.48Kcal/Kg, this fuel oil is a kind of good heating fuel which can be applied for boiler factory, cement factory, boilers, glass factory and steel mill, etc.

Carbon black (30%):

Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

It is more price-efficient to be used as an ingredient in the industries listed:

1.Cement factory

2.Conveyor band

3.Carrier Bands

4.Hose and doormat

5.Black nylon bag

6.Rubber additive

7.Heat isolation

Steel wire(15%)

Steel wire can be sold to steel factory directly.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating continuous waste tire to fuel oil pyrolysis plant;no waste emission.

- 4.Auto welding to ensure continuous waste tire to fuel oil pyrolysis plant life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do continuous waste tire to fuel oil pyrolysis plant project plan,including financial analysis.

Help customer finished continuous waste tire to fuel oil pyrolysis plant delivery,foundation,installation,trainning,commissioning and try running.

One year warranty period .

If you are intrested in investment continuous waste tire to fuel oil pyrolysis plant ,or any other questions,such as project report,project cost,you can leave a message in below form, we will back to you once we got your message.

Leave a inquiry for continuous waste tire to fuel oil pyrolysis plant: