Recycling plastic bottles to fuel oil machine

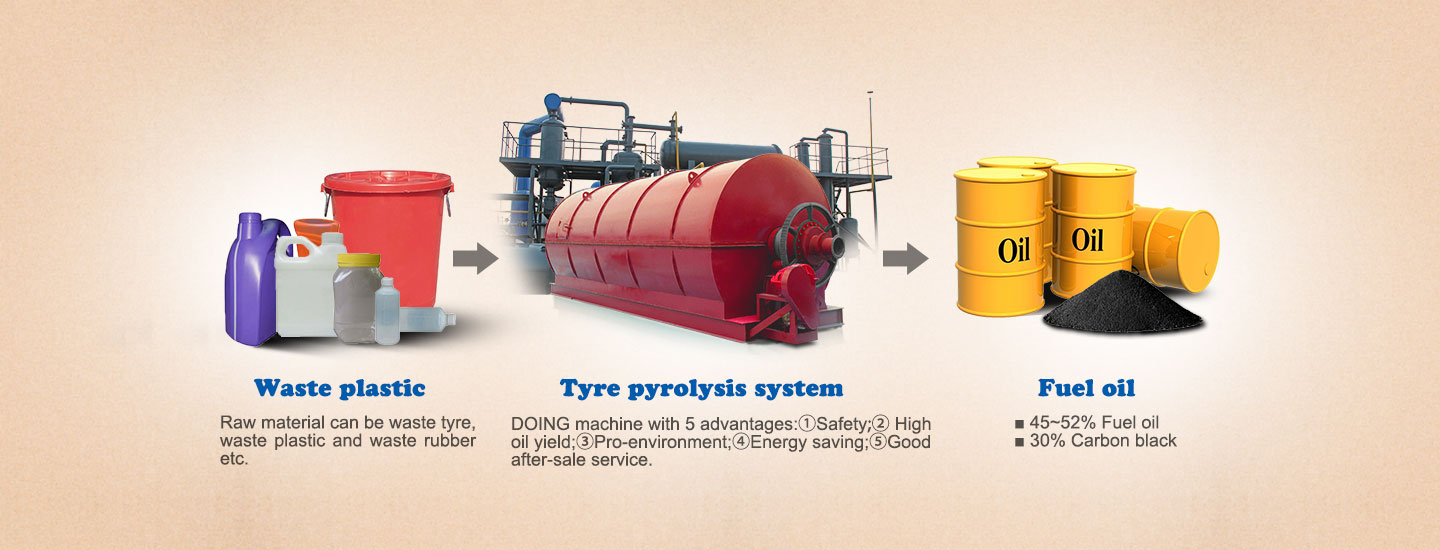

Recycling plastic bottles to fuel oil machine briefly introduction:

Recycling plastic bottles to fuel oil machine

Plastics are durable and degrade very slowly; the molecular bonds that make plastic so durable make it equally resistant to natural processes of degradation. Since the 1950s, one billion tons of plastic has been discarded and may persist for hundreds or even thousands of years.

Plastic bottles Recycling Solutions:

One of potential option is the conversion of plastics into fuel oil by thermal depolymerization or pyrolysis process. Such a pyrolysis process would be able to accept almost any polymer or mix of polymers, including rubber tires. Like natural petroleum, the chemicals produced can be made into fuels as well as polymers.

Definition of Pyrolysis:

Pyrolysis is the chemical decomposition of condensed organic substances by heating. The word is coined from the Greek-derived elements pyro "fire" and lysys "decomposition". Pyrolysis is usually the first chemical reaction that occurs in the burning of many solid organic fuels, like wood, cloth, and paper, and also of some kinds of plastic. Anhydrous pyrolysis can also be used to produce liquid fuel similar to diesel from plastic waste.

The pyrolysis process for plastic takes the long chain polymer molecules and breaks or cracks them into shorter chains through heat and pressure. Essentially the process is mimicking the natural process of the earth to break down carbon into oil which takes million of years in nature. The pyrolysis process does this with intense heat in a closed system in a short amount of time.

Conditions for producing pyrolysis oil are more likely to include virtually no oxygen. The pyrolysis of plastics produces a liquid product, pyrolysis oil or oil that can be readily stored and transported. Pyrolysis oil can be used directly as fuel or further refined into diesel or jet fuel.

Recycling plastic bottles to fuel oil machine

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating recycling plastic bottles to fuel oil machine;no waste emission.

- 4.Auto welding to ensure recycling plastic bottles to fuel oil machine life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do recycling plastic bottles to fuel oil machine project plan,including financial analysis.

Help customer finished recycling plastic bottles to fuel oil machine delivery,foundation,installation,trainning,commissioning and try running.

One year warranty period .

If you are intrested in investment recycling plastic bottles to fuel oil machine ,or any other questions,such as project report,project cost,you can leave a message in below form, we will back to you once we got your message.

Leave a inquiry for recycling plastic bottles to fuel oil machine: