Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Feasibility analysis report of waste plastic to oil pyrolysis project

Some investors were surprised when they first know the waste plastic to oil pyrolysis project and wondered if it would work. Next, DOING company will make a feasibility analyze report of the waste plastic to oil pyrolysis project from the following aspects.

Waste plastic to oil pyrolysis project

Waste plastic to oil pyrolysis project

Development prospect of waste plastic to oil pyrolysis project

With the rapid development of the world plastic industry, more and more plastic materials are used widely than before. As the increasing quantity application of plastic, it brings people convenience as well as serious pollution problems. At present, the waste plastics mainly are solved by landfill, burning and recycling. However, both of landfill and burning cause the secondary pollution, and the scope plastic recycling is very limited. For example, the waste plastics produced by household garbage and paper-making factory, which cannot be recycled.

Waste plastics produced by household garbage and paper-making factory

Waste plastics produced by household garbage and paper-making factory

While with the increasing price of international crude oil, the waste plastic to oil pyrolysis projects are closely watched by different countries in the world. This waste plastic to oil pyrolysis project can not only avoid the pollution problem caused by the waste plastics, but also bring huge economic benefits.

DOING waste plastic to oil pyrolysis plant

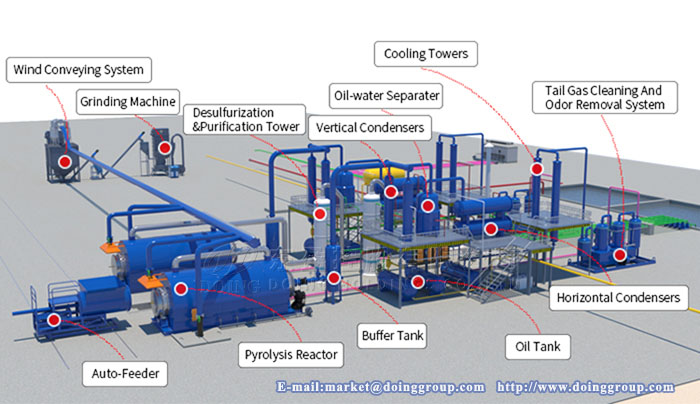

In this case, DOING company spent many years to research and develop a high efficiency, energy saving, environmental protection waste plastic to oil pyrolysis plant. As shown in the figure below, the waste plastic to oil pyrolysis plant is mainly composed of pyrolysis reactor, heating furnace, condensing system, oil tank, oil-water separator, buffer tank, tail gas purification system, carbon black discharge device, desulfurization & purification tower, etc.

Main parts of waste plastic to oil pyrolysis plant

Main parts of waste plastic to oil pyrolysis plant

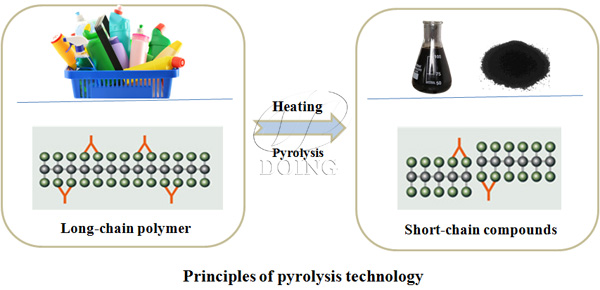

Principle of pyrolysis technology

Pyrolysis technology is the industrial process of breaking down large molecules of plastic/tire into smaller molecules of oil gas and carbon black. The pyrolysis technology of waste plastic not only no pollution to the environment but also recycle the energy effectively. That is to say, pyrolysis technology of plastic is the inverse process of manufacturing plastic products by crude oil materials. Our DOING company add different catalyst to the different plastic materials for pyrolysis. Comparing with the domestic pyrolysis technology, we improve the oil yield and quality.

Principle of pyrolysis technology

Principle of pyrolysis technology

Suitable waste plastic and their oil yield

The main waste plastics suitable for the pyrolysis plant is PE, PP, PS, ABS, etc. The molecules of different plastic is very different, so the final product and oil yield is different. Generally, there are four kinds of final pyrolysis products: hydrocarbon gas(C1-C5), oil (gasoline is C5-C11,diesel oil is C12-C20, the heavy oil is C20), paraffin and coke. The following figure shows the oil yield of some typical plastic.

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

Technical parameter of waste plastic to oil pyrolysis plant

| Technical parameter of waste plastic to oil pyrolysis plant | |||||

| Items | Contents | ||||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 | DY-1-12 |

| 2 | Raw material | tires/Plastic | tires/Plastic | tires/Plastic | tires/Plastic |

| 3 | 24-hour Capacity | 6 ton | 8 ton | 10 ton | 12ton |

| 4 |

Marerial of Reactor |

Q245R | Q245R | Q245R | Q245R |

| 5 |

Thickness of Reactor |

16mm | 16mm | 16mm | 16mm |

| 6 | Total power | 17KW | 17KW | 19KW | 19KW |

| 7 |

Cooling area of condenser |

60sqm | 60sqm | 100sqm | 100sqm |

| 8 | Noise dB(A) | ≤85 | ≤85 | ≤85 | ≤85 |

| 9 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 | 2800×6600 |

| 10 | Delivery time | 20days | 20days | 20days | 20days |

| 11 | Weight | 26T | 28T | 30T | 32T |

Advantages of DOING waste plastic to oil pyrolysis plant

High efficiency

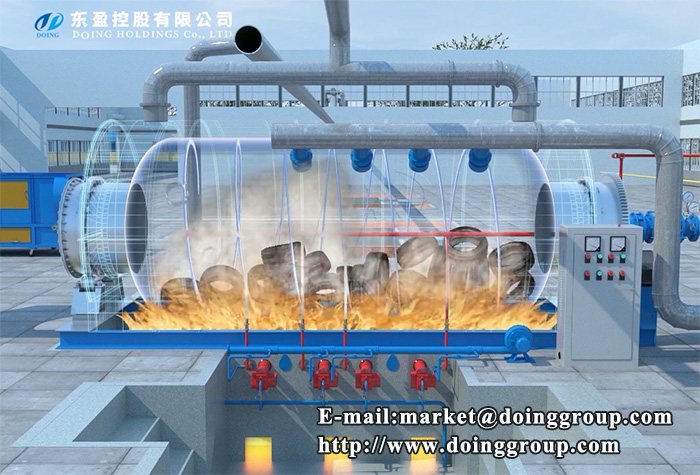

The pyrolysis reactor designed by DOING can rotate 360 degrees. This special design makes the bottom of reactor heat evenly, which allows the raw materials inside the reactor to be uniformly heated, greatly increasing the operating efficiency of the waste plastic to oil pyrolysis plant. This design can also longer the life spans of pyrolysis reactor.

Special design of pyrolysis reactor

Special design of pyrolysis reactor

Energy saving

In the process of pyrolysis, some combustible gas cannot be converted into oil liquid in normal temperature and pressure, which could be recycled to the bottom of the reactor for reheating through the pipe of tail gas. In this way, it can avoid the gas contamination and save the fuel energy.

Environmental protection

In order to ensure the environmental protection of the production process, the harmful gas generated in the pyrolysis process and the tail gas generated from fuel combustion will be treated through the tail gas cleaning and odor removal system and desulfurization & purification tower. So that the whole pyrolysis process is environmental protection.

Desulfurization & purification tower

Desulfurization & purification tower

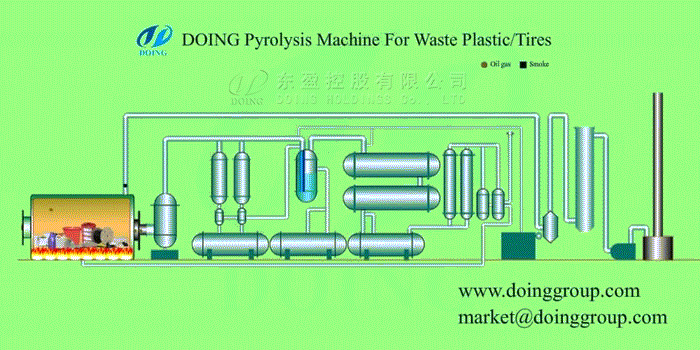

Waste plastic to oil pyrolysis plant working process

The whole working process of waste plastic to oil pyrolysis plant is in normal pressure. Waste plastics can be put into the reactor for pyrolysis directly, and then heating, catalyzing, pyrolysis and cooling into fuel oil. The main workflow is as follows.

Working process of waste plastic to oil pyrolysis plant

Working process of waste plastic to oil pyrolysis plant

Optimum oil production temperature for different plastics

Because the plastic is made of different raw material, the production temperature of pyrolysis process is also a little different. For example, PE, PP and PS are decomposed at 300-400 centigrade degrees. But the PVC is decomposed at two stages which are 200-300 and 300-400 centigrade degrees. The PVC may release HCL and hydrocarbon, and then break down step by step.

Treatment of three industrial wastes

Smoke

Our tail gas cleaning and odor removal system has a more complicated and scientific design than others in removing the dust and sulfur. Add the catalyst liquid into the circulating water and use high-pressure hydraulic pump to press this water into high pressure nozzle (also can be called Spray Scrubber) which can first atomize the water, then reactor with sulfur dioxide while, at the same time, absorb the dust in the smoke. After the process of our dust removal system, the color of the smoke is white, which means our waste plastic to oil pyrolysis plant can reach the international purification standard and will not cause pollution to the environment. In addition, we have done the EPA and SGS test.

Tail gas cleaning and odor removal system

Tail gas cleaning and odor removal system

Carbon black

After the pyrolysis process of waste plastic, it will produce some waste residue which the weight is nearly 5-10% of the plastic. For these carbon black, we have designed a carbon black wind transfer system which is totally sealed & no dust. It can collect the carbon black through the sealed pipeline, without any pollution to the environment.

Carbon black wind transfer system

Carbon black wind transfer system

Waste water

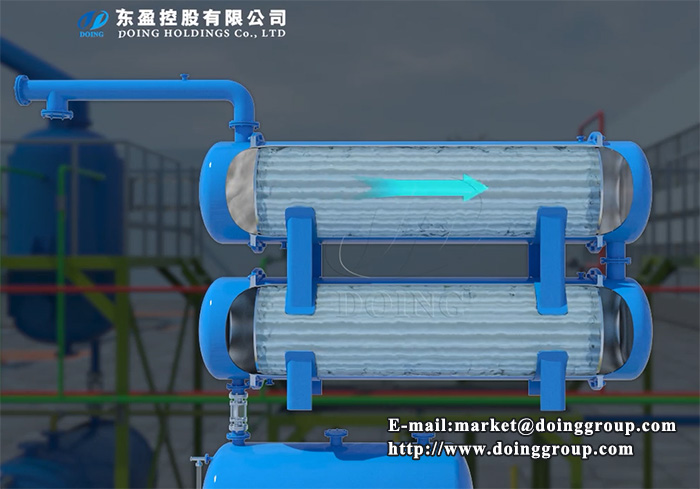

In the whole pyrolysis process, only condensers and cooling devices need circulating water to cool the system. The cooling system of our waste plastic to oil pyrolysis plant all adopt shell and tube condensers. Water only goes through between the shell and inner tube for cooling the oil gas going through the inner tube. This way, water has no contact with oil gas, thus would not become dirty. And water is for circulating use, no consumption, no discharge.

Circulating water in cooling system

Circulating water in cooling system

Economic benefit analysis

| Profit analysis(Reference to process 12T/D waste plastic to oil pyrolysis plant) | |

| Running cost / Day | |

| Waste plastics | 12T*40USD/T=876USD |

| Heating fuel (Just choose one from the options) | 1)Coal: 0.4T¥*58USD/T=23USD 2)Fuel oil: 0.4T*364USD/T=146USD 3)Diesel:0.3T*582USD/T=175USD 4)Natural gas: 150M3*0.33USD/M3=4.9USD |

| Power consumption | 15Kw/h |

| Water consumption | Water is for circulating use, no consumption |

| Required workers | 3 workers per shift * 22USD =65USD |

| Income / Day | |

| Fuel oil | 4.5T*364USD/T=1637USD |

| Carbon black | 1)selling directly,3T*73USD/T=218USD 2)grinding,3T*291USD/T=873USD |

| Daily profit (Use fuel oil for heating and sell carbon black directly) | 1523USD/Day |

Investment recovery analysis: take this waste plastic to oil pyrolysis plant for example, it can be finished installing in 30 days. All the investment can be recovered in two months.

Conclusion

According the above analysis of waste plastic to oil pyrolysis project, waste plastic to oil pyrolysis plant can convert the waste to treasure, and is benefit for the nation and the people. It is feasible on the technology. It has the advantages of low investment, enough raw materials, short-term, and good prospects. So the waste plastic to oil pyrolysis plant project is a very good choice to invest.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications