The cost of a certain device you want

Get started today and complete our form to request your free estimate

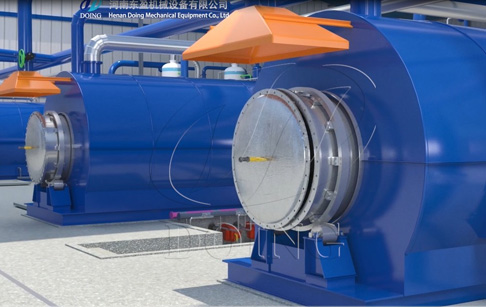

- Waste Plastic Recycling Pyrolysis Plant

- Waste Tyre Recycling Pyrolysis Plant

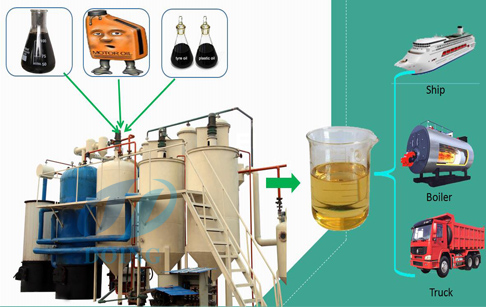

- Tyre/Plastic Oil to Diesel Distillation Plant

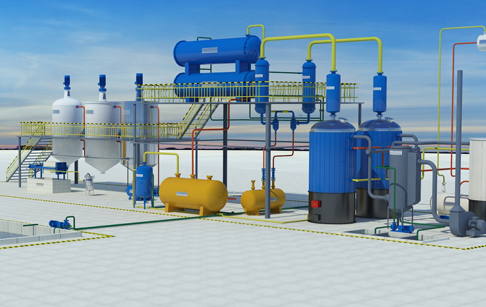

Controlled and manipulated pyrolysis plant recycling processes

Pyrolysis control

©2019 DOING GROUP

Oil Gas Thermometer

Note:

In order to enlarge users' experience, Here is a simulation work station of waste tyre pyrolysis plant, let the user to know the machine working process.Pls click the left button to begin operate:First step: Add tyre → Second step: Add fuel → Third step: Power on → Last step: Fire.

The button "reset" can let the machine from start. The thermometer is the oil gas tempreture( It is the best oil quality when oil gas reach 230 degree). Press 'switch' button to show or hide the annotation.Thanks.

Chamber

Separator

Separator

Device

Device

-

Panama customer expansion tire pyrolysis project completes second installation

Due to the expansion of production scale, our old customer in panama has completed the installation of the waste tyre recycling pyrolysis plant.Now, t...

-

One set waste tyre to oil pyrolysis plant installed in Gansu, China

On January 11, 2019, good news came from Gansu, China — the installation of one set 10T/D waste tyre to oil pyrolysis plant was successfully complete...

-

4 sets 12T/D used tyre recycling pyrolysis equipments being installed in Fujian, China

4 sets used tyre recycling pyrolysis equipments being installed from our engineer in Fujian, China. the installation of the used tyre recycling pyroly...

Our waste tyre pyrolysis plant and tyre oil distillation plant can get diesel from waste tyres, which can be used directly on tractors.

3D demonstration video for new generation waste tyre recycling pyrolysis plant

DOING GROUP introduction with its pyrolysis machine

Refined tyre oil can using in tractor engine directly

India 50 Tons/Day Continuous Pyrolysis Plant Video: Waste Tyre to Oil Products

Semi continuous oil sludge treatment pyrolysis machine in Malaysia Video

DOING Scrap Tire Recycling Pyrolysis Plant Operated in Sri Lanka Video

Most popular video recommendations

-

India 50 Tons/Day Continuous Pyrolysis Plant Video: Waste Tyre to Oil Products

-

Semi continuous oil sludge treatment pyrolysis machine in Malaysia Video

-

DOING Scrap Tire Recycling Pyrolysis Plant Operated in Sri Lanka Video

-

Pyrolysis Plant Feedstock: Recyclable Waste Raw Materials Introduction Video

-

DOING Oil sludge recovery pyrolysis machine operation site video in Colombia

- Company news

- Industry news

-

15

2026-01Indian Customer Ordered for DOING 100kg Skid-mounted Plastic Pyrolysis Unit

In January 2026, an Indian customer ordered for DOING 100kg skid-mounted plastic pyrolysis unit from DOING company, which is designed to flexibly test...

-

25

2025-08DOING Secured Order for 2 Sets of 15TPD Batch XLPE Plastic Pyrolysis Machine from Indian Customer

In August 2025, DOING secured an order from an Indian customer for 2 sets of 15TPD batch XLPE plastic pyrolysis machine after visiting the factory, re...

-

09

2025-12DOING 10TPD Batch Plastic Pyrolysis Equipment Dispatched to Indonesia

In November 2025, DOING dispatched a 10TPD batch plastic pyrolysis equipment to Indonesia, which helps convert waste plastic into fuel for the client...

-

11

2025-09Polish Customer Signs Contract for 36000TPY Fully Continuous Rubber Powder Pyrolysis Machines

In August 2025, DOING successfully signed a contract with a Polish customer for a 36,000-ton/year fully continuous pyrolysis machine with its advanced...

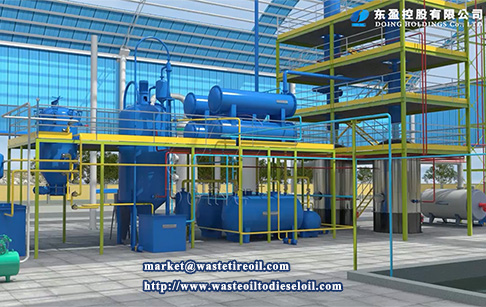

Henan Doing Environmental Protection Technology Co., Ltd, the subsidiary company of Doing Holdings Co., LTD, is a comprehensive environmental equipment manufacturer integrating technological design, research and development, machine production, sales and after-sales service in one.

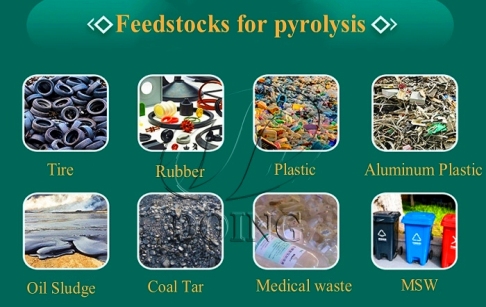

Our main business: solid waste and hazardous waste treatment equipments, pyrolysis plant and related environmental protection equipments including waste tire recycling pyrolysis plant, waste plastic recycling pyrolysis plant, waste oil sludge pyrolysis plant, waste oil distillation plant with the tail gas cleaning, flue gas desulfurization and purification equipments, as well as scrap cable wire, circuit board and other metal plastic separation equipments, etc.

We not only possess an independent technology R&D team who have obtained a number of utility model patents and invention patents, but also have the professional manufacturing team and after-sales team to guarantee you the product quality and user experience. Therefore, our E-commerce and marketing team can cooperate with these teams to provide you the best one-stop service. Besides, we have branches and overseas warehouses in Nigeria, with professional overseas sales and after-sales team, and our factory and warehouses have the whole set of advanced model machines. You are welcome to have a visit at any time.

-

Professional technical team design, development

-

Skilled machine loading and customs clearance

-

Professional engineers guide the installation

-

Equipment debugging and operation training

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications