Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

How Can Waste Plastic Bags Be Disposed?

Plastic, also known as white pollution, has long plagued governments and individuals worldwide. Among the myriad of plastic wastes, waste plastic bags are particularly prevalent. They are ubiquitous in daily life but pose significant environmental challenges once discarded. Traditional waste disposal methods such as landfill and incineration often fail to effectively address plastic bag pollution and may even lead to secondary pollution issues. Against this backdrop, pyrolysis technology has garnered increasing attention as an environmentally friendly and resource-efficient solution for handling waste plastic bags.

Waste plastic bag pyrolysis

Principles of Plastic Pyrolysis

Plastic pyrolysis is a chemical process that breaks down plastic into smaller molecules under high-temperature conditions in the absence of oxygen. During this process, the long molecular chains of plastic are fragmented into smaller molecular chains, transforming the plastic into oil gas. Subsequently, the oil gas is cooled to produce pyrolysis oil. This pyrolysis oil can be further refined into diesel through waste oil distillation machine, making it a valuable energy resource.

Waste plastic bags pyrolysis technology

Advantages of Pyrolysis Technology

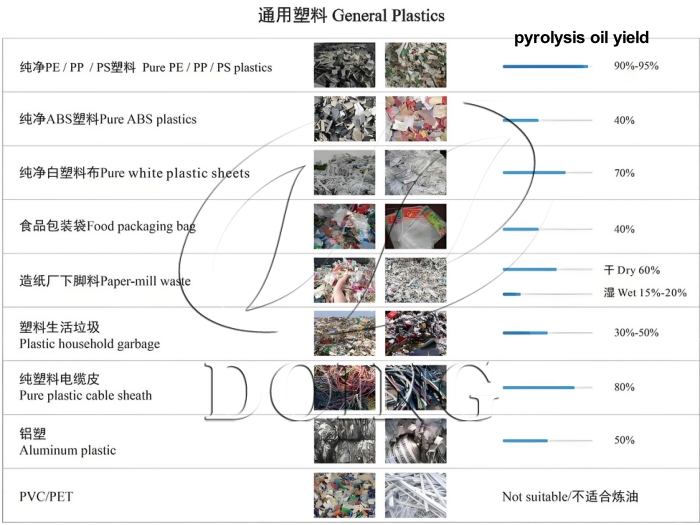

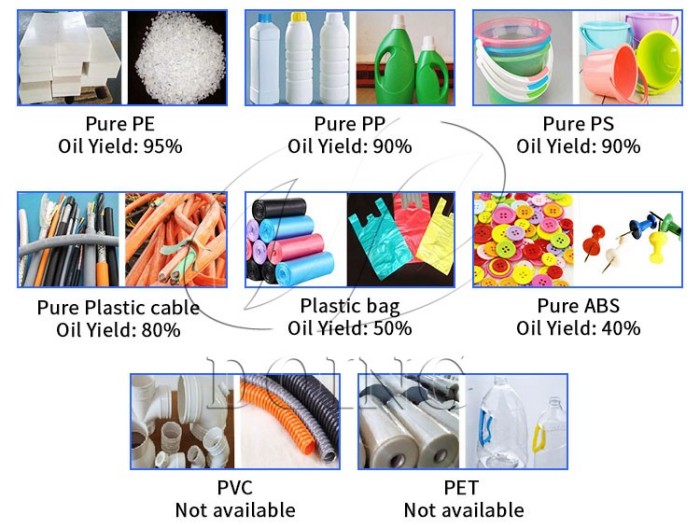

High Oil Yield: If waste plastic bags primarily consist of polypropylene (PP), polystyrene (PS), and polyethylene (PE), the pyrolysis oil yield can reach up to 90%. Even for mixed plastic bags, the pyrolysis oil yield remains between 40%-60%. After distillation and refining, the diesel yield from pyrolysis oil can reach approximately 85%.

Waste plastic pyrolysis oil yield

Wide Range of Applications for Final Products: The fuel oil produced can be used to steel factory, boiler heating, heavy oil generator, cement factory, etc. Additionally, the 10% tail gas generated during the process can be directly used to heat the reactor, reducing fuel consumption.

Waste plastic bags pyrolysis products and products applications

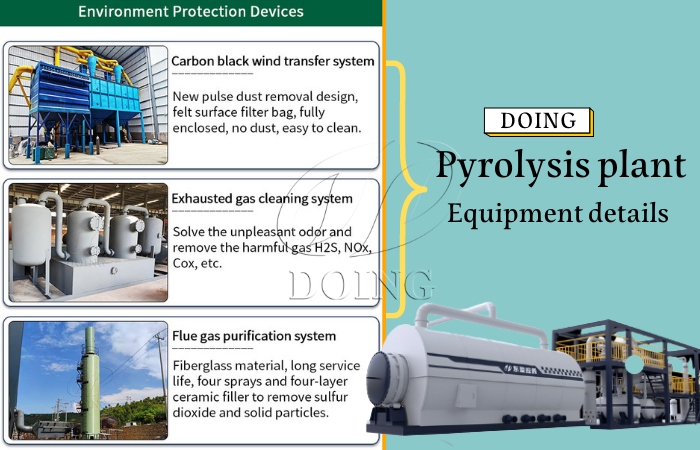

Environmentally Friendly: Pyrolysis technology can convert waste plastic bags into useful products. The pyrolysis machine is equipped with environmental protection devices to ensure the process is green and eco-friendly, effectively avoiding secondary pollution.

DOING plastic pyrolysis machine environment protection devices

Applicable Materials

Most types of plastics can undergo pyrolysis, with the exception of PVC and PET. However, if the content of PVC and PET in the waste plastic bags does not exceed 10%, pyrolysis can still proceed.

Raw plastic materials for pyrolysis

Pyrolysis Process

Pre-treatment: Waste plastic bags are first sorted to remove impurities such as metal, paper, and food residues. They are then cleaned and dried to enhance pyrolysis efficiency and oil yield.

Pyrolysis: The pre-treated plastic bags are fed into the pyrolysis machine. Under high-temperature conditions, the plastic molecules break down, generating oil gas.

Condensation: The oil gas is cooled through a condenser to produce liquid pyrolysis oil, which is collected in a storage tank.

Post-treatment: The carbon black produced during the pyrolysis process is discharged and can be processed into building materials, pigments or other uses. The small amount of exhaust gas produced is purified through environmental protection devices before being discharged to prevent air pollution.

In conclusion, pyrolysis technology offers an effective solution for disposing of waste plastic bags. It not only alleviates environmental pollution but also converts waste into valuable resources, generating economic benefits. If you want to engage in this business, welcome contact DOING, we will provide you with professional guidance and services throughout the process.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.