Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

DOING Secured Order for 2 Sets of 15TPD Batch XLPE Plastic Pyrolysis Machine from Indian Customer

In August 2025, DOING secured an order from an Indian customer for 2 sets of 15 TPD batch-type cross-linked polyethylene (XLPE) plastic pyrolysis machine.The core goal of this cooperation is to enable the Indian customer to efficiently process cross-linked polyethylene (XLPE) plastic waste and achieve profitable resource recycling.

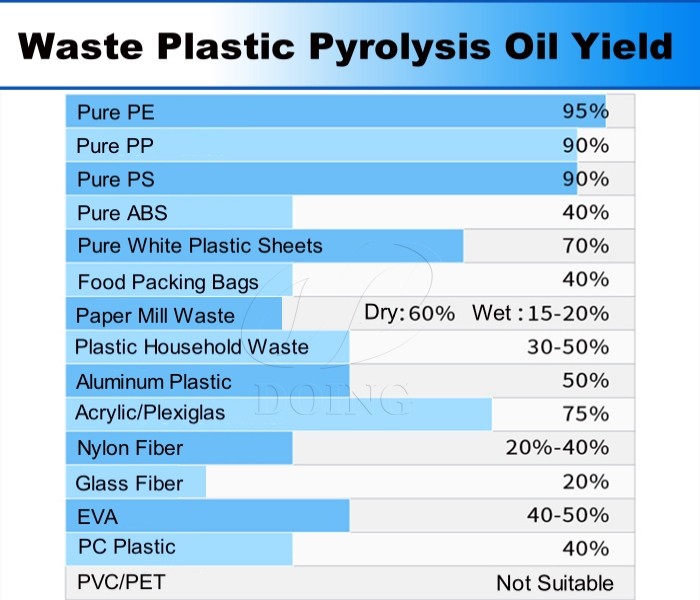

Plastic Pyrolysis Oil Yield

Plastic Pyrolysis Oil Yield

During discussions with DOING business manager, the Indian customer highlighted two core requirements: plastic pyrolysis machine quality and stable operation duration. These two factors directly influence the long-term profitability and operational efficiency of the recycling project, making them non-negotiable for the Indian customer.

To thoroughly verify DOING comprehensive strength, the Indian customer arranged a visit to our factory in July 2025. Accompanied by our team, the Indian customer inspected the production workshop, witnessed the entire plant manufacturing process, and reviewed the strict quality control system in detail. This on-site tour allowed the Indian customer to gain first-hand insight into DOING production capabilities and product standards.

DOING factory display

DOING factory display

DOING business manager maintained close communication with the Indian customer to fully grasp their specific operational needs, with a focus on emphasizing how equipment reliability and operational efficiency can drive project success. After in-depth analysis, our team recommended a rear slag removal system for the pyrolysis machine. This system offers a key advantage: after the pyrolysis process is completed, the carbon black by-product can be cooled down and directly conveyed into bulk bags via a screw conveyor, greatly streamlining the Indian customer’s post-processing workflow and enhancing operational efficiency.

The on-site factory inspection fully demonstrated DOING solid production strength, mature manufacturing technology, and reliable product quality, which won high recognition from the Indian customer. Upon returning to India in August 2025, the Indian customer wasted no time in confirming the cooperation details and officially placing an order for 2 sets of 15TPD batch XLPE plastic pyrolysis machine.

DOING plastic pyrolysis plant in India

DOING plastic pyrolysis plant in India

DOING has always focused on the research, development, and innovation of waste recycling equipment. We are committed to providing more efficient, reliable, and targeted solutions for global Indian customer facing diverse waste treatment challenges. For more information about DOING plastic pyrolysis machine and international cooperation cases, please feel free to contact us.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications