Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

DOING Successfully Installed 15TPD Batch Oil Sludge Pyrolysis Equipment in China

In March 2025, DOING successfully installed a 15TPD batch oil sludge pyrolysis equipment for a chemical industry client in China. This equipment is specifically designed to extract 50-60% residual oil from hazardous waste, namely catalyst filter cake.

Client Profile

The client operates within the chemical sector, focusing on recycling waste engine oil and lubricating oil, as well as managing hazardous waste through the recycling of oil sludge and residues. In their daily operations, they produce substantial amounts of catalyst filter cakes that contain significant residual oil but are categorized as hazardous waste. With an increasing volume of these filter cakes, the client sought to implement pyrolysis technology to recover the residual oil for further use. In December 2023, they reached out to DOING to explore reliable pyrolysis options.

Oil-containing catalyst filter cake

Oil-containing catalyst filter cake

Detailed Negotiation and Tailored Solution Development

Following comprehensive discussions, DOING business manager gained insight into the client's raw material properties and equipment requirements. The catalyst filter cakes presented challenges such as high viscosity, corrosiveness, and a tendency to coke during pyrolysis—issues that needed to be effectively managed by the equipment. To demonstrate feasibility, DOING shared data from similar existing and upcoming projects, using coal tar residue pyrolysis equipment as a reference.

Operation of DOING oily sludge pyrolysis equipment in China

Operation of DOING oily sludge pyrolysis equipment in China

Based on the characteristics of the feedstock, both parties agreed on a batch oil sludge pyrolysis equipment solution, which included several key customized features:

1. Material for Pyrolysis Furnace: 304 stainless steel was chosen for its high temperature and corrosion resistance, which helps minimize coking and sticking on the furnace walls, thereby reducing the frequency of shutdowns for cleaning and ensuring smoother production flow.

2. Integrated Decoking Device: A dynamic scraping mechanism was included to eliminate coking layers from the furnace walls, preventing excessive build-up that could hinder heat transfer and efficiency. This innovation significantly reduces maintenance downtime and enhances the operational efficiency and longevity of the pyrolysis equipment.

3. Insulation and Sealing Features: The thermal insulation cover of the pyrolysis furnace utilizes specialized materials to maintain effective thermal insulation during the process and ensure tight sealing, which helps prevent fire hazards and smoke emissions.

DOING oil sludge pyrolysis project in China

DOING oil sludge pyrolysis project in China

Following this, DOING technical team collaborated with the client’s technical department to finalize the detailed configurations and layout of the plant. To support the client’s project advancement, DOING also assisted with the Environmental Impact Assessment (EIA) by providing necessary technical information and environmental protection strategies.

Finalizing Cooperation and Timely Delivery

In September 2024, after several rounds of confirmations, the client officially partnered with DOING and placed an order. Adhering to stringent quality control and production timelines, DOING completed the manufacturing of the entire set of batch catalyst filter cake pyrolysis recovery equipment by March 2025. After thorough quality checks, inventory, and packaging, the equipment was shipped from the DOING factory to the client’s site.

Shipping oil sludge pyrolysis equipment to China

Shipping oil sludge pyrolysis equipment to China

Comprehensive Technical Support and Installation Assistance

From the moment of shipment to on-site installation, DOING provided full-spectrum technical support and guidance. Upon the arrival of the 15TPD batch oil sludge pyrolysis equipment at the project location, DOING sent a professional installation team to oversee the construction, ensuring that installation and initial commissioning adhered strictly to the established plans and specifications. Currently, the equipment has been installed and is undergoing trial operations, with positive feedback received from the client regarding its performance.

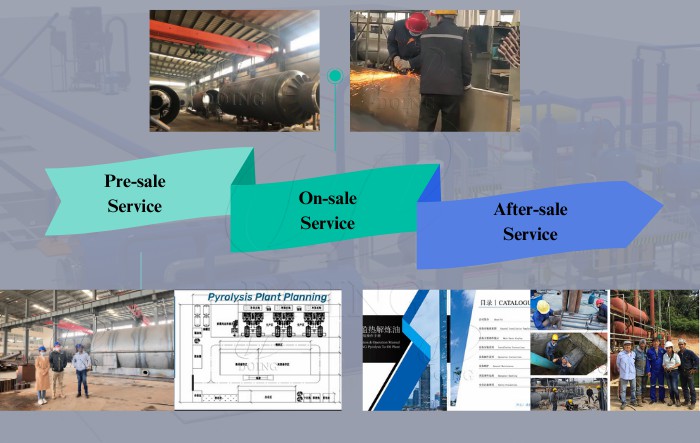

DOING provide complete service

DOING provide complete service

This project showcases DOING expertise in crafting customized solutions for hazardous waste pyrolysis and delivering comprehensive services. Looking ahead, DOING remains committed to advancing research and development in waste recycling technology, aiming to offer more efficient, environmentally friendly, and reliable solutions for clients globally. For further information on DOING pyrolysis equipment, please reach out to us today.

Get More Project Information

Please leave your contact information and details of the DOING Successfully Installed 15TPD Batch Oil Sludge Pyrolysis Equipment in China you want to know so that our professional team can contact you as soon as possible.