Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

DOING High Oil Yield Batch Tyre Pyrolysis Device Helps Myanmar Customer Achieve Fuel Self-Sufficiency

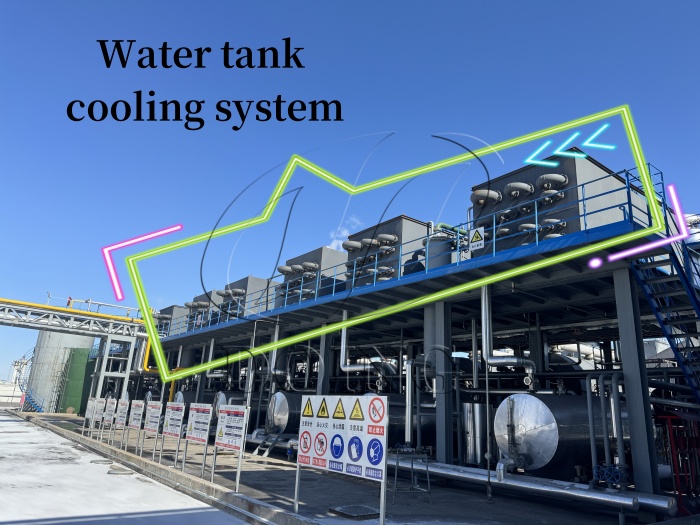

In any pyrolysis device, the efficiency of converting high-temperature steam into liquid fuel oil is crucial to profitability. In the three 15-ton high oil yield batch pyrolysis devices we installed in Myanmar in January 2025, the water tank condensation system was key, designed to achieve maximum fuel oil production for the Myanmar customer's tyre recycling pyrolysis project.

DOING batch tyre pyrolysis device in Myanmar installation site

Our customer operates a mining and lime plant in Myanmar and decided to undertake a tyre pyrolysis project with the goal of achieving fuel self-sufficiency. Therefore, the installation of the condensation system was crucial. After understanding the customer's details, we recommended a water tank condensation system.

DOING batch tyre pyrolysis device in Myanmar delivery

DOING's core advantages in water tank condensing systems:

1 Superior condensing efficiency and high-quality oil output: A large-area water tank design provides ample cooling space, effectively converting the oil and gas produced during pyrolysis into high-quality liquid pyrolysis oil. This significantly improves oil recovery rates and maximizes customer economic benefits.

2 Reliable structure and long service life: Constructed with robust steel and featuring advanced anti-corrosion treatment, it effectively resists corrosive gases generated during pyrolysis and long-term water immersion.

3 Safe and reliable operation: Equipped with a water seal design, it effectively prevents air from entering the system, preventing oil and gas leaks and potential fire risks, ensuring operational safety. The cooling medium is circulating water, which is inexpensive and readily available, making operation safer and more environmentally friendly.

4 Excellent environmental performance: Effectively condensing oil and gas reduces the emission of uncondensed harmful gases, meeting increasingly stringent environmental regulations. This contributes to the resource utilization of waste and supports a circular economy.

5 Easy installation and maintenance: Compared to complex condensing systems, the water tank design is more compact, and the installation process is relatively simple and quick. Low daily maintenance costs and easy operation.

DOING batch tyre pyrolysis device water tank condensation system

The robust installation of this water tank condensation system ensures that the high-temperature pyrolysis vapors from tyres are quickly and effectively cooled and converted into high-quality&high calorific value fuel oil (approximately 10,000 to 11,000 kcal, about 44.32 MJ/kg). For our Myanmar customers, this means achieving self-sufficiency in fuel for both mining and lime plant boiler heating by maximizing the extraction of fuel oil from waste tire materials, thus saving on fuel investment costs.

DOING batch tyre pyrolysis device in Myanmar installation site

DOING batch tyre pyrolysis device manufacturer

DOING is committed to providing customers with comprehensive and optimized high-performance pyrolysis recovery solutions. We will recommend the optimal equipment configuration based on your specific needs to ensure your pyrolysis business achieves maximum efficiency. If you are considering starting a pyrolysis business or would like to learn more about DOING pyrolysis devices, please contact us.

Get More Project Information

Please leave your contact information and details of the DOING High Oil Yield Batch Tyre Pyrolysis Device Helps Myanmar Customer Achieve Fuel Self-Sufficiency you want to know so that our professional team can contact you as soon as possible.