Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

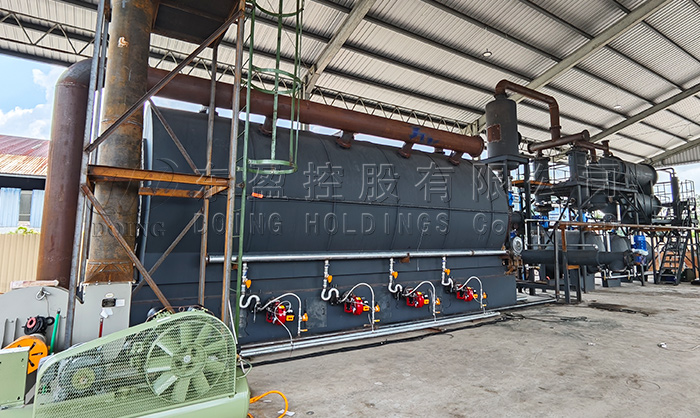

DOING Tank Cleaning Sludge Pyrolysis Equipment Installed in Colombia

From June 12 to July 10, 2025, DOING's overseas after-sales team completed the installation and commissioning of the tank cleaning sludge pyrolysis equipment for a prestigious Colombian customer. The DOING tank cleaning sludge pyrolysis equipment, with its high efficiency and quality, empowers the Colombian oil sludge pyrolysis refining project, injecting significant momentum into the project and accelerating the implementation of this green utilization project.

Colombian tank cleaning sludge pyrolysis project site

Project Background

This Colombian customer is engaged in the waste oil recycling industry and has a stable supply of oil sludge raw materials. Their initial collaboration with DOING was to explore new technologies to address a series of issues currently plaguing their factory's old equipment, including coking and sticking to the walls, frequent manual cleaning, and low production efficiency. Therefore, in 2023, they purchased four sets of 15-ton stainless steel tank cleaning sludge pyrolysis equipment from our company. Six months after their official operation, they were very satisfied with the equipment's overall performance, production efficiency, and the design of its anti-coking and wall-sticking technology. In 2024, they signed another procurement contract with DOING, placing a centralized order for 12 sets of pyrolysis equipment with the same specifications and configuration. The scale of this oil sludge pyrolysis project continues to expand, and the industrial chain continues to upgrade.

Core Equipment

The tank cleaning sludge pyrolysis production line provided by DOING consists of a feeding system (oil sludge pump), a pyrolysis system (stainless steel pyrolysis main furnace), a heating system (heating furnace), a condensing system (oil-water separator, catalyst chamber, horizontal condenser, vertical condenser, condensing tower), a slag discharge system (cooling and slag discharge auger), and an exhaust gas purification system (water seal tank, deodorization tower).

Colombian tank cleaning sludge pyrolysis project site

Taking advantage of the fluidity and viscosity of tank cleaning sludge, DOING designed a sludge pump for the feed process, ensuring that the material can be fed and pyrolyzed in a closed, oxygen-free environment. The main pyrolysis furnace is constructed from a custom-made 304 stainless steel inner shell. This material provides a smoother, less sticky sludge, and a pendulum-type decoking device is installed within the furnace. As the furnace rotates, it mechanically scrapes away sludge and coke clumps from the inner walls, addressing a range of issues caused by sludge coking and wall adhesion.

Equipment Advantages

1. High Production Efficiency and Significant Economic Benefits: DOING's tank cleaning sludge pyrolysis equipment utilizes a semi-continuous process design, with sealed feeding at the front and high-temperature sludge removal at the rear. Compared to traditional processes, this eliminates the need for furnace cooling and can process three furnaces of sludge in two days, achieving high efficiency and significant economic benefits.

DOING semi-continuous pyrolysis equipment post-slag discharge process

2. Long equipment lifespan and low maintenance costs: The pyrolysis furnace's inner shell is made of stainless steel, which is more corrosion-resistant and heat-resistant than carbon steel. This prevents bulging, deformation, and burn-through from long-term thermal expansion and contraction. Furthermore, the stainless steel shell reduces coking and wall adhesion of oil sludge during the pyrolysis process, reducing the need for frequent manual de-coking and extending the equipment's service life.

3. High degree of automation, saving labor costs: The equipment is equipped with a PLC intelligent control system, automating the entire pyrolysis process, from raw material input to finished product output. This not only saves significant labor costs but also improves crude oil production efficiency, fully meeting the high-volume production needs of the Colombian customer.

Colombian tank cleaning sludge pyrolysis project site

Delivery Site

Due to the large order volume for this Colombian customer, the equipment production schedule will be extended. To ensure the smooth progress of the customer's oil sludge pyrolysis refining project, DOING Company adopted a batch-by-batch production and delivery method. The equipment was manufactured, quality-tested, and shipped in three separate batches, in February and May 2025. DOING's overseas engineers are also ready. Once the equipment arrives at the port, clears customs, and takes delivery, they will immediately travel to the Colombian oil sludge pyrolysis project site to provide on-site guidance on installation and commissioning.

DOING tank cleaning oil sludge pyrolysis equipment delivered to Colombia

Project Site

Colombian tank cleaning sludge pyrolysis project site

Colombian tank cleaning sludge pyrolysis project site

Currently, the Colombian customer's 12 tank cleaning sludge pyrolysis equipment sets have been fully commissioned, and the production lines are operating at full capacity, continuously producing high-quality crude oil for the customer. Under normal circumstances, the oil yield from tank cleaning sludge pyrolysis is between 70-80%, depending on the feedstock conditions. A high yield indicates high oil quality. In addition to crude oil, the residue in the refined sludge is less than 0.03%, meeting harmless landfill standards. A small amount of combustible gas, after purification, is directly returned to the furnace for heating, saving additional fuel consumption and reducing operating costs.

Products of tank cleaning sludge pyrolysis: pyrolysis oil and slag

DOING sincerely wishes the Colombian customer's oil sludge pyrolysis project a smooth start-up and high production and increased revenue. DOING Holdings will continue to provide after-sales support to help the customer achieve long-term, stable operations and mutually beneficial development!

Get More Project Information

Please leave your contact information and details of the DOING Tank Cleaning Sludge Pyrolysis Equipment Installed in Colombia you want to know so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications