Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

FAQ

Turning plastic into oil machine

Turning plastic into oil machine will play a great role in solving the environmental pollution caused by waste plastics discarded and buried at will, and bring economic benefits to customers engaged in waste plastics recycling.

We provide free trial service.

You can also visit our factory.

- Tel: +86-13526692320

- WhatsApp: +86-13526692320

- Phone: +86-37156771821

- Email: sales@doinggroup.com

Turning plastic into oil machine is suitable for recycling waste plastics. The application of turning plastic into oil machine will not only play a great role in solving the environmental pollution caused by waste plastics discarded and buried at will, but also bring certain economic benefits to customers engaged in waste plastics recycling.

Turning plastic into oil machine installed

Turning plastic into oil machine installed

The details of turning plastic into oil machine are as follows:

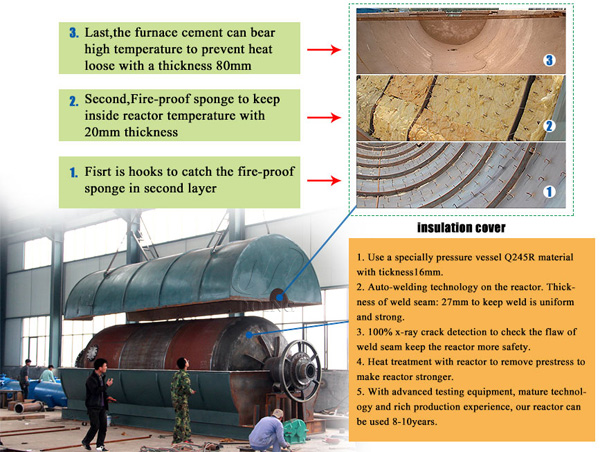

The reactor of turning plastic into oil machine is made from Q245R boiler plate, which can be heated by coal, wood, oil, natural gas and other heating materials. After the installation of the machine, it will take up about 500 square meters of land.

The feture of reactor

The feture of reactor

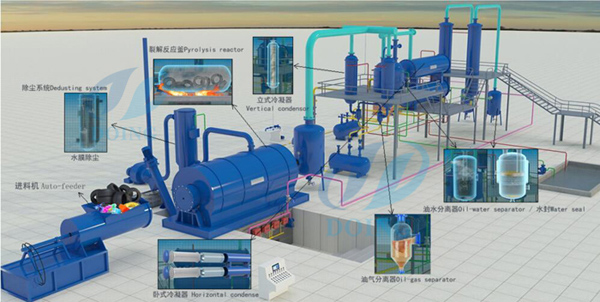

The main operating procedures of turning plastic into oil machine:

1. Feeding. Because plastic melts faster than tires, it will take four to five operations to complete the entire feed, and the reactor can hold 12 tons of waste plastic. If the waste plastic is wet, it will take about 7 hours to feed. If the waste plastic is dry, it takes four hours. Because if the plastic is wet, when you heat it up, the water in the waste plastics will becomes water vapor, and then the waste plastic starts to melt. So wet plastic takes longer to feed. So for the wetter waste plastics, the reactor of turning plastic into oil machines is like a dryer and you would better dry the waste plastics before you start the pyrolysis reaction.

2. Heating for pyrolysis reaction. After the feeding of waste plastic is completed, if the plastic is wet, oil gas will be generated after 6-8 hours, and the oil gas will last for 15-28 hours before all the oil gas can be discharged from the reactor. In the process of producing oil gas, the optimum temperature should be controlled.

3. Cool the generated oil gas. Most of the oil gas will be cooled into liquid state.

4. Carbon black can be discharged after the oil gas is exhausted and the reactor is cooled for 2 hours.

The main operating procedures of turning plastic into oil machine

The main operating procedures of turning plastic into oil machine

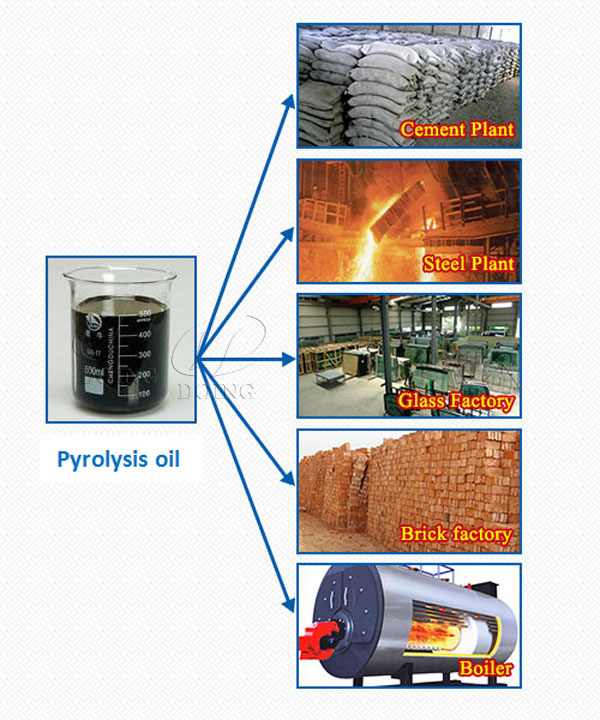

The end products of turning plastic into oil machine are mainly plastic pyrolysis oil and carbon black.

Plastic pyrolysis oil and carbon black have great USES in industry:

Plastic pyrolysis oil: can be used as industrial fuel combustion, mainly used in steel mills, heavy oil generators and cement plants ,etc.

The use of pyrolysis oil

The use of pyrolysis oil

Black carbon: the black carbon emitted by turning plastic into oil machine is crude. It can be sold as internal combustion fuel to brick factories or further refined to produce new tires and rubber products.

The use of carbon black

The plastic pyrolysis oil and carbon black from the turning plastic into oil machine can be sold directly and get certain economic benefits. It is believed that the environment we live in will be better and better after the plastics are turned into oil by turning plastic into oil machine.

Request a Quote for the Turning plastic into oil machine

Please leave your contact information and Turning plastic into oil machine requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications