Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Plastic to Oil Pyrolysis Process

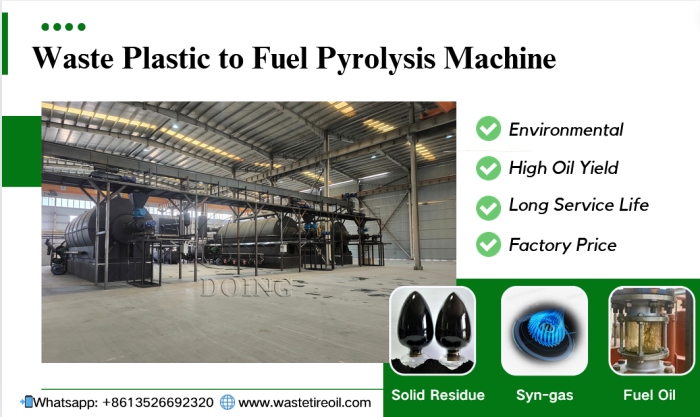

In order to recycle and manage waste plastics in a green and profitable way, Henan DOING Company has developed plastic waste pyrolysis machine, which refers to converting waste plastic into fuel oil and carbon black through high temperature, with both economical and environmental benefits.

Waste plastic to oil pyrolysis process

Waste plastic to oil pyrolysis process

1.Plastic Pyrolysis Process Principle

Plastic pyrolysis is the thermal decomposition of plastic waste at different temperatures (280–400°C) in the absence of oxygen, to produce liquid fuel oil(pyrolysis). It involves the molecular breakdown of larger plastic molecules into smaller molecules of oil gas and carbon by using heat.

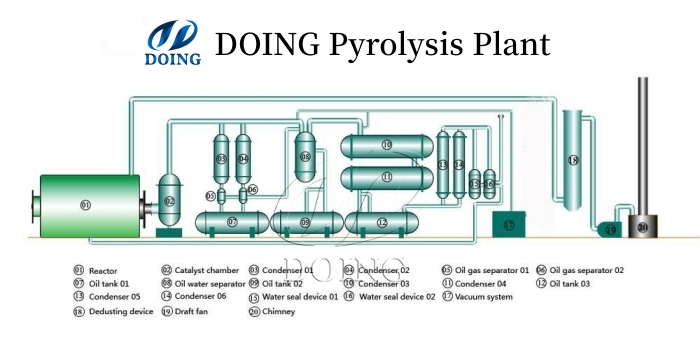

Waste plastic to oil pyrolysis process design

Waste plastic to oil pyrolysis process design

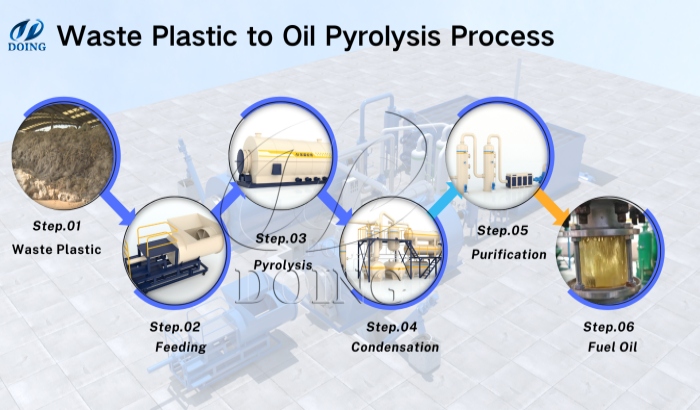

2.Plastic Pyrolysis to Oil Process Steps

Plastic pyrolysis is a process that involves the thermal decomposition of plastic waste to produce fuel or other valuable products. Here are the general steps involved in plastic to fuel oil pyrolysis process:

Waste plastic to oil pyrolysis process diagram

Waste plastic to oil pyrolysis process diagram

A. Waste Plastic Pretreatment

Drying: remove moisture content and improve the pyrolysis efficiency.

Shredding: If you adopt semi-continuous type or fully automatic waste plastic pyrolysis machine, waste plastic waste should be shredded into smaller pieces to increase the surface area for better heat transfer during the subsequent pyrolysis process.

B. Heating for Pyrolysis

The dried and shredded plastic is then fed into a pyrolysis reactor, where it undergoes a thermochemical decomposition process in the absence of oxygen. The plastic is heated to high temperatures, typically ranging from 300 to 800 degrees Celsius, causing it to break down into various gaseous, liquid, and solid products.

C. Pyrolysis Oil Condensation

The gaseous products produced during pyrolysis, such as hydrocarbons and other volatile compounds, are passed through a condensation system. This system cools the gases, causing them to condense into liquid products. The condensed liquids can include pyrolysis oil, which can be further processed for various applications.

D. Exhaust Gas Purification

The exhaust gas generated in the pyrolysis and pyrolysis machine reactor heating process will go through the environmental protection devices for dedusting and filtration. This step is essential to ensure that the released gases meet environmental standards and to prevent the release of pollutants.

E. Plastic Pyrolysis Final Products Collection

The final step involves collecting the end products of the plastic to fuel oil pyrolysis process. These final products of plastic pyrolysis machine may include:

Pyrolysis oil: A liquid fuel that can be used for heating or as a feedstock for producing non-standard diesel

Syn-gas: The uncondensable gas generated in plastic pyrolysis process---syngas may be utilized for heating plastic pyrolysis machine reactor to save energy investment.

Carbon black: The remaining solid material after pyrolysis has applications as a carbon source or for other uses.

3.Plastic to Oil Pyrolysis Process Project Display Video:

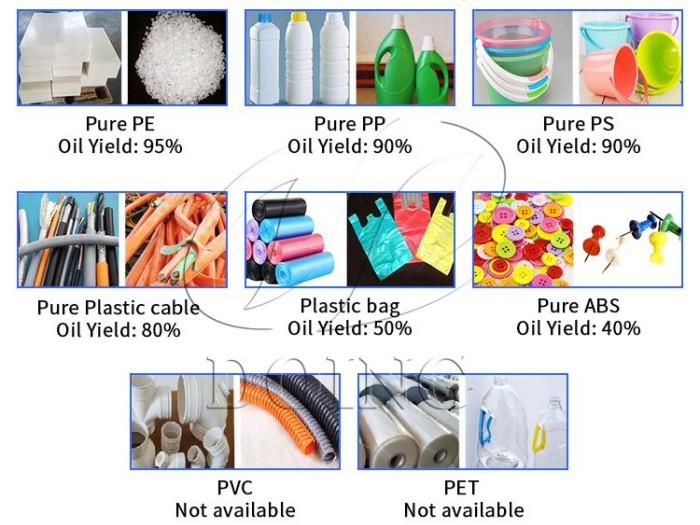

4.Plastic waste materials selection for pyrolysis process:

Pyrolysis technology can convert a variety of plastic waste into resources such as fuel oil, such as PE, PP, PS, ABS, household plastic waste, medical waste plastic, domestic plastic waste, paper mill waste, etc., but not all plastics(except PVC and PET plastic). Different plastics have different yields of pyrolysis products. When applying it, factors such as plastic type, pyrolysis machine configuration design and product processing capacity need to be considered.

waste plastic pyrolysis feedstocks and oil output

waste plastic pyrolysis feedstocks and oil output

5.Plastic Pyrolysis Plant Purchase Scheme

Executing the plastic to oil pyrolysis process requires a specialized production line – waste plastic pyrolysis machine. This waste plastic to oil recycling machine consists of feeding system, pyrolysis reactor, combustors, oil gas condensation system, exhaust purification system, etc. The detailed configurations of waste plastic pyrolysis machines for different customers' requirements are different.

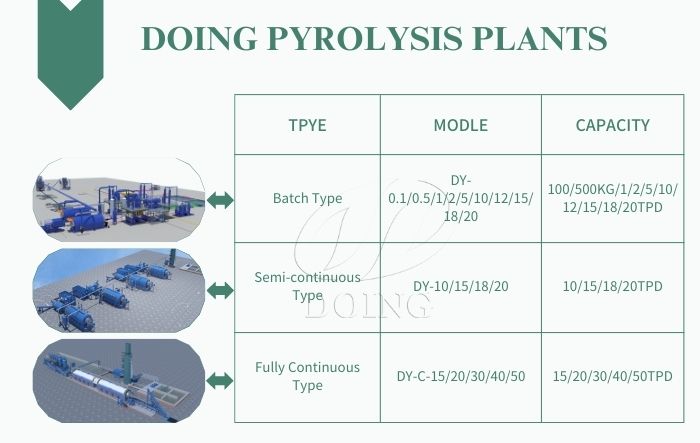

Processing capacity of DOING waste plastic pyrolysis machines for sale

Processing capacity of DOING waste plastic pyrolysis machines for sale

As an experienced and reputable pyrolysis machine manufacturer, we Henan-Doing have designed three models of waste plastic pyrolysis machines to choose from: batch model, semi-continuous model and fully continuous model. These machines are engineered to withstand high temperatures and maintain an oxygen-free environment, ensuring the smooth operation of the plastic to oil pyrolysis process. Their processing capacities vary from 100kg per batch to 50 ton per day/set, covering small to big industrial plastic to oil pyrolysis processing scales.

Welcome to send your enquiry to Henan Doing Company to get customization solutions for waste plastic to fuel oil pyrolysis process, for maximizing the yield and profit of valuable end products and minimizing environmental impact.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.