Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

What regeneration products can waste oil be recycled into?

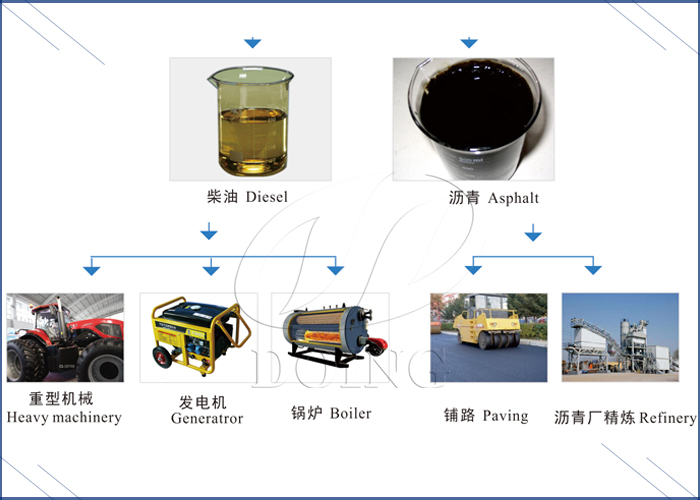

Various types of waste oil, including waste engine motor oil, tire plastic pyrolysis oil, heavy oil, and used lubricant oil, can be efficiently processed using a waste oil recycling machine to produce diesel fuel, while also yielding a valuable by-product: Bitumen (asphalt).

Waste oil recycling regeneration products

Waste oil recycling regeneration products

The diesel extracted from waste oil can be directly utilized in tractors, trucks, ships, generators, and heavy machinery. Additionally, the residual material can be employed for road paving or sold to asphalt plants for further refining. Both diesel and bitumen have extensive market demand, offering significant profit potential. Moreover, by collecting and recycling waste oil, these waste oil recycling machines play a crucial role in reducing environmental pollution and its adverse effects.

Applications of diesel and bitumen extracted from waste oil

Applications of diesel and bitumen extracted from waste oil

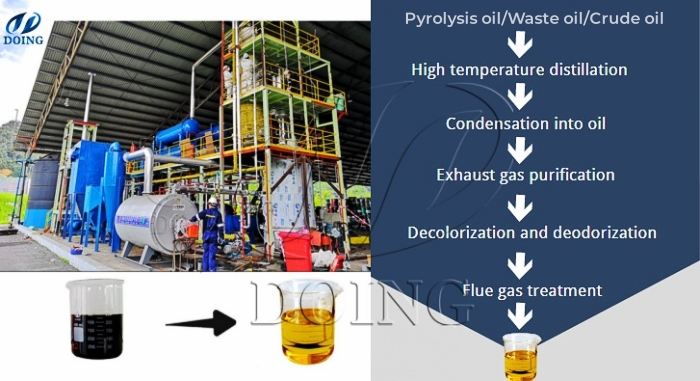

But how exactly is diesel produced from recycled waste oils? Below are the steps involved in the waste oil processing procedure to obtain diesel and bitumen:

Initially, the collected waste engine oil is injected into the distillation reactor of our waste oil recycling machine. Through the thermal oil heating system and the fuel heating system, the waste oil undergoes boiling and gasification. Impurities within the waste oil continue to settle during the heating process, while the remaining oil gas is catalyzed and enters the condensation system.

The oil and gas pass through the solid catalytic tower, where reactants remove colloids and waxes from the oil and gas produced by the waste oil. After degumming and dewaxing, the oil becomes clearer.

Subsequently, the oil and gas flow into the condensation system after catalytic reaction and cooling, transforming into diesel before entering the temporary storage tank.

Waste oil to diesel recycling process

Waste oil to diesel recycling processThe diesel refined from the waste oil refining diesel equipment is pumped into the decolorization system. The decolorized diesel becomes clearer and brighter.

The non-condensable part of the gas passes through the water seal system before being transported to the heating chamber via a special gas nozzle for complete combustion.

To address the smoke and dust emitted during fuel combustion, the waste oil refining diesel equipment is equipped with a specially designed desulfurization and dust removal purification system. After processing, the flue gas emits white smoke, mainly composed of water vapor and carbon dioxide, meeting national emission standards.

The residue remaining after distillation consists of heavy oil impurities with properties similar to asphalt, which are collected at the bottom of the distillation reactor and discharged using a bitumen pump.

Waste oil to diesel recycling machines for sale

Waste oil to diesel recycling machines for sale

Through these steps, valuable regeneration products—diesel and bitumen—are obtained from waste oil. Henan Doing Company offers high-efficiency waste oil recycling machines for sale with various capacities. Feel free to send us your inquiry to find the appropriate one for your needs at favorable prices.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications