Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Pyrolysis-recycling Utilization in Composite Plastic Materials

Composite plastics are made by combining multiple materials, typically polymers with reinforcing agents like fibers, metals, or resins. These materials provide superior strength, durability, and flexibility, making them essential in industries such as automotive, aerospace, and construction. Traditional recycling methods often fail to separate the different components effectively, which is why new, innovative recycling technologies are necessary.

DOING waste composite plastic pyrolysis machine

DOING waste composite plastic pyrolysis machine

Pyrolysis recycling has emerged as a promising solution for composite plastics, pyrolysis is a thermal decomposition process conducted in the absence of oxygen, converts these non-recyclable plastics into valuable hydrocarbon products such as pyrolysis oil, syngas, and carbon black. This article explores the composition and types of composite plastics, the advantages of various recycling methods, and how DOING plastic pyrolysis machines offer an efficient and sustainable alternative.

The composition and types of composite plastics

Composite plastics are made from polymers combined with other materials to enhance their properties. The key components include:

1.Polymer Matrix:

The base plastic material, such as polyethylene (PE), polypropylene (PP), or epoxy, which holds the composite together.

2.Reinforcing Agents:

Materials like glass fibers, carbon fibers, or natural fibers, which improve the mechanical strength of the composite.

DOING waste composite plastic pyrolysis machine

DOING waste composite plastic pyrolysis machine

3.Resins and Additives:

Chemical agents used to bind the materials and improve properties like fire resistance, UV stability, and flexibility.

4.Metals:

Such as aluminum in aluminum-plastic composite plastics, electronic waste such as copper and aluminum in copper wire/PCB and other mixed metals.

Common types of composite plastics include:

1.Glass Fiber Reinforced Plastics (GFRP):

Used in automotive, marine, and construction applications.

2.Carbon Fiber Reinforced Plastics (CFRP):

Found in aerospace, sports equipment, and high-performance vehicles.

3.Polymer Blends:

Mixtures of different polymers designed to enhance specific properties for targeted applications.

The complex composition and diverse sources of composite plastic raw materials lead to a variety of recycling methods, making recycling difficult and costly. The following are common recycling methods for composite plastics.

1. Mechanical Recycling

Pros: Simple and low cost for single-material plastics. Suitable for basic recycling.

Cons: Ineffective for composite plastics, as it cannot separate different components, leading to low-quality recycled materials.

2.Chemical Recycling

Pros: Can break down complex plastics into base chemicals, which can be reused in new applications.

Cons: Requires significant energy and is still not widely adopted for composite plastics due to the complexity of the process.

3. Pyrolysis Recycling (The Most Efficient Option)

DOING waste composite plastic pyrolysis technology

DOING waste composite plastic pyrolysis technology

Pros: DOING plastic pyrolysis machine converts composite plastics into valuable products like pyrolysis oil, metal, carbon black, and synthesized gas. Moreover, the pyrolysis equipment is highly tolerant in processing various plastic wastes such as composite plastics and mixed plastics, and there is almost no need for sorting requirements for separate types of plastics.

Cons: The initial investment in pyrolysis machines can be high, but the long-term benefits, such as fuel production and waste reduction, far outweigh this cost.

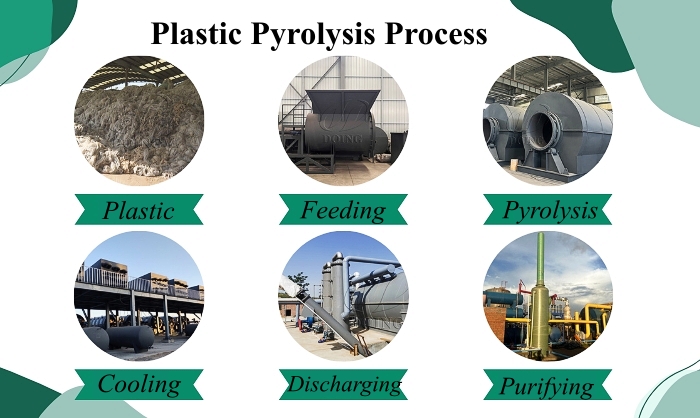

Process of DOING plastic pyrolysis machine

1.The first step is feeding.

The entire composite plastic feeding process takes only 1.5 to 2 hours for two workers to fill a pyrolysis reactor with a daily processing capacity of 12-15 tons plastic pyrolysis recycling machine.

2.The second step is pyrolysis.

DOING waste composite plastic pyrolysis process

DOING waste composite plastic pyrolysis process

After feeding, the burner is turned on to heat the pyrolysis reactor, evaporating the moisture from the waste plastic. The temperature then gradually rises to 200°C. The burner is controlled to maintain the temperature between 230 and 260°C. This is the oil production stage, which lasts for four hours.

3.The third step is the condensation stage.

Our cooling systems include water tank cooling and water tank cooling, which efficiently converts oil vapor into oil. Both condensers use circulating cooling water, achieving zero wastewater discharge.

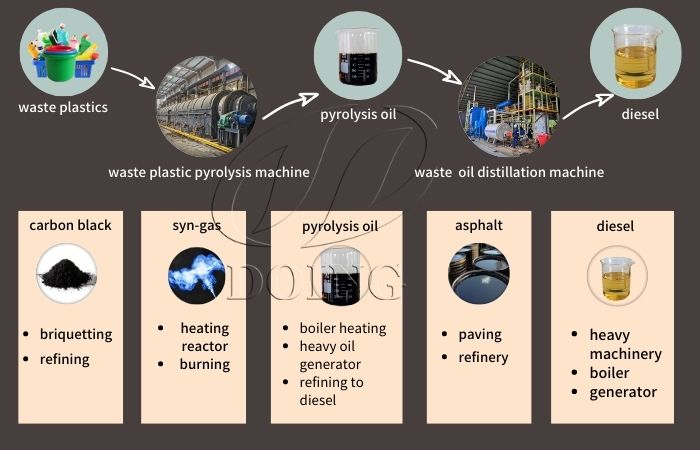

How businesses can benefit from composite plastic pyrolysis-recycling

1. Low Investment, High Return

Compared to traditional recycling methods, pyrolysis technology is more economical and affordable. The cost of obtaining waste composite plastics is low, the process is highly efficient, and the resulting byproducts are high-value, resulting in high profits: pyrolysis oil can be used as alternative fuels for boiler plants, steel mills, gypsum plants, brick factories, etc.. the gas can be used as a fuel for heating boilers or as a feedstock for some chemical reactions; The recovered metal can be sold directly on the market or recycled and reused, and the market price is extremely high. and the carbon black can be used in the rubber industry to improve the performance of rubber products or in the production of pigments.

DOING waste plastic to diesel process

DOING waste plastic to diesel process

2. Reduced Dependence on Fossil Fuels

Composite plastics present a significant environmental challenge. By converting them into useful products, pyrolysis helps reduce landfill waste, lower CO2 emissions, and reduce dependence on fossil fuels.

3. Increased Efficiency

Compared to other methods, pyrolysis machines offer higher processing efficiency and are more energy-efficient. The exhaust gas generated is recycled for self-heating, making it self-sufficient.

4. Versatile Selectivity

Pyrolysis works for all composite plastic types—whether GFRP, CFRP, or polymer blends—without complex pre-sorting or separation. DOING plastic pyrolysis equipment offers processing capacities ranging from 0.1 to 50 TPD, suitable for both small and large projects, enabling businesses to efficiently recycle varying quantities and types of waste plastics.

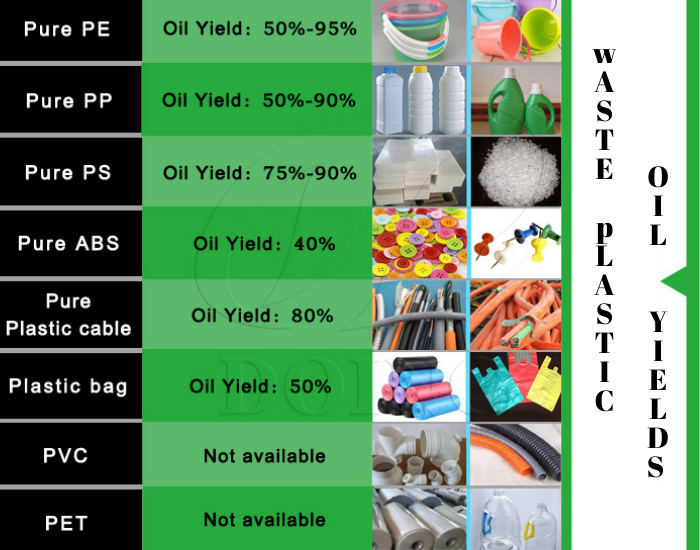

Waste plastic pyrolysis oil yield

Waste plastic pyrolysis oil yield

The recycling of composite plastics presents significant challenges, but pyrolysis-recycling technology offers an efficient and environmentally friendly solution. For businesses looking to reduce waste costs, cut carbon footprints, and tap into new revenue streams, pyrolysis-recycling of composite plastics is not just an option—it’s a necessity. Welcome to contact DOING for composite plastics pyrolysis recycling solution.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.