Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

From "Black Pollution" to "Black Gold": Pyrolysis Technology is Reshaping Tire Recycling Industry

Each year, approximately one billion tires are discarded globally, a staggering volume that could encircle the Earth multiple times if stacked. These once-problematic "environmental hazards," notorious for their persistence, potential to release toxins, breeding grounds for pests, and fire risks, have long posed significant challenges for governments and environmental agencies worldwide.

However, driven by pyrolysis technological innovation and supportive policies, the fate of end-of-life scrap(ELTs) tires is undergoing a profound transformation. What were once environmental burdens are now being recognized as valuable resources, yielding valuable products like pyrolysis oil and carbon black. From landfill nightmares to lucrative circular economy ventures, pyrolysis technology is giving discarded tires a new lease on life.

Pyrolysis plant as waste tire recycling solution

Pyrolysis plant as waste tire recycling solution

The Evolution from "Black Pollution" to a Waste Management Challenge

In the past, the disposal of used tires presented a formidable challenge, characterized by high treatment costs and the risk of secondary pollution. The accumulation of vast quantities of discarded tires not only consumed land but also exerted continuous pressure on the ecological environment.

Breakthroughs in Tire Recycling Pyrolysis Technology

The key to transforming used tires into valuable resources lies in advanced tire pyrolysis technology. Henan DOING Company, with a decade of dedicated research and development, has overcome critical technical hurdles in used tire processing and recycling. Our optimized processes deliver environmentally friendlier solutions with lower energy consumption and higher product value.

Through the pyrolysis process, used tires can be converted into four high-value products: pyrolysis oil, carbon black, steel wire, and combustible gas. For instance, 10 tons of truck tires can yield approximately 4.5 tons of pyrolysis oil, 1.5 tons of steel wire, and 3.5 tons of carbon black – a transformation akin to turning waste tire black pollution into black gold.

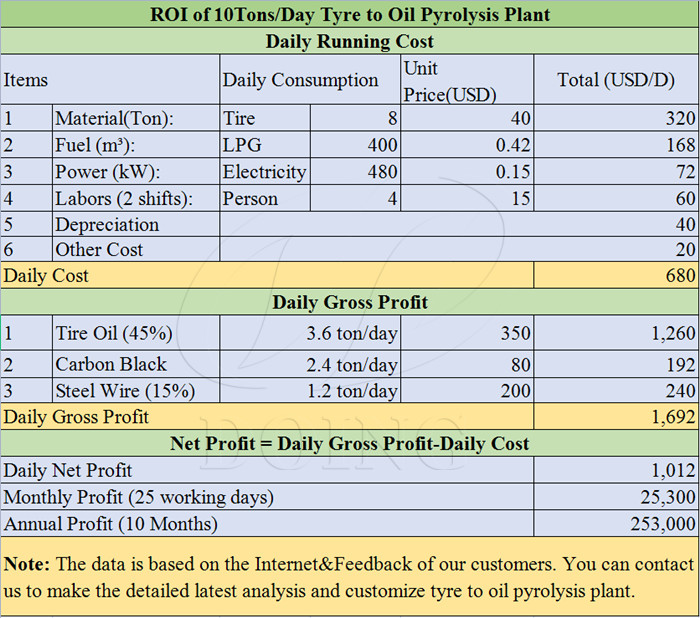

10 ton waste tire recycling pyrolysis plant profit analysis

10 ton waste tire recycling pyrolysis plant profit analysis

Moreover, the value of pyrolysis products can be significantly enhanced through further refining and upgrading. For example, pyrolysis oil can be processed into higher-grade diesel fuel oils, and carbon black can be briquetted for heating or refined into fine powder, which greatly expands their application scopes.

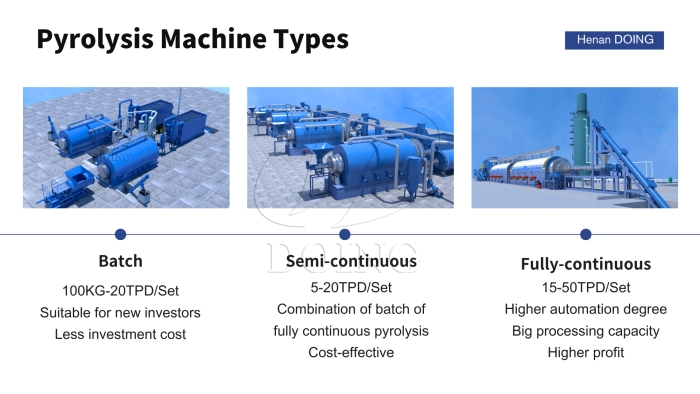

China's advancements in tire pyrolysis technology have established it as a strong market competitor. Not only are the outputs diverse, but the focus is increasingly shifting towards cutting-edge sectors like new energy and high-end manufacturing, paving the way for the elevated value of used tires. Henan Doing Company is a reliable and world-leading pyrolysis plant manufacturer in China, we have developed Fully Automatic Type / Semi-continuous Type / Batch Type of tire pyrolysis equipment with different capacities to meet different customers’ tire recycling requirments. These technological revolutions is fundamentally rewriting the narrative of tire recycling industry.

Comparision of three types of tire recycling pyrolysis equipment

Comparision of three types of tire recycling pyrolysis equipment

A "Value Goldmine" for the Circular Economy

The recycling and regeneration of used tires is not just solving an environmental problem; it's also fostering a thriving, multi-billion-dollar circular economy industry. In China alone, over 1,500 enterprises are engaged in the comprehensive utilization of used tires, processing an estimated 230 million tires annually. Here are the business profit opportunities and other benefits of tire recycling pyrolysis industry:

Using the example of tire pyrolysis technology, processing 60,000 tons of used tires can generate approximately 24,000 tons of pyrolysis oil and 22,000 tons of carbon black, leading to an annual revenue of 11,245,040 USD. After deducting operational costs, this business still demonstrates robust profitability. More importantly, the tire pyrolysis process significantly reduces carbon dioxide emissions. It's estimated that processing 60,000 tons of tires can cut CO2 emissions by around 6 million tons, equivalent to planting one million mu of forest. This not only strongly supports national carbon neutrality goals but also injects vital momentum into green construction and sustainable development.

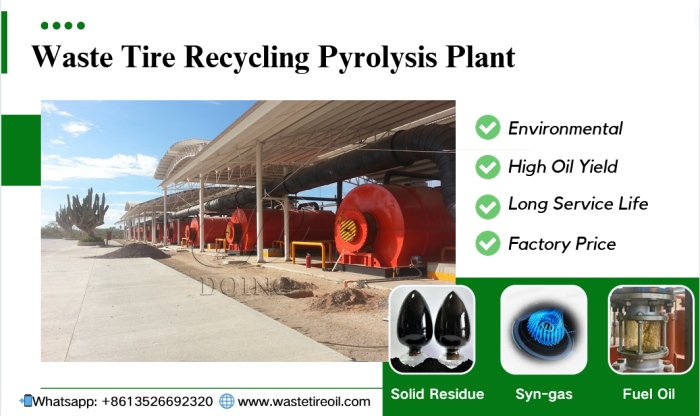

Waste tire recycling pyrolysis machine benefits

Waste tire recycling pyrolysis machine benefits

Supported by national waste treatment policy subsidies and tax rebates, the pyrolysis oil and carbon black generated from tire pyrolysis can effectively substitute industrial fuel oil and traditional carbon black, thereby opening up broad market profit margins.

The flourishing tire recycling industry has also greatly boosted employment and regional economies. Many pyrolysis plants are established on underutilized land, creating thousands of local jobs, attracting diverse talent, and stimulating regional consumption.

Recycling tire into fuel oil and carbon black through pyrolysis technology

Recycling tire into fuel oil and carbon black through pyrolysis technology

Currently, advanced pyrolysis technology is progressively gaining global recognition. Henan DOING's pyrolysis equipment has been successfully exported to numerous countries with high volumes of discarded tires, including India, Vietnam, Malaysia, Thailand, Indonesia, Pakistan, Iran, Saudi Arabia, USA, and Turkey, contributing to the green circular utilization of used tires worldwide. With its mature tire pyrolysis technology, Henan DOING empowers clients to master the core technique of transforming "black pollution into black gold," achieving high returns and collectively moving towards a sustainable future.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.