Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Can all kinds of waste plastic be converted to fuel?

Pyrolysis is a recycling technology that converts plastic waste into usable energy (such as pyrolysis oil, syn-gas, gasoline, diesel, etc.). This process is usually carried out in an oxygen-free or low-oxygen environment, and the plastic is pyrolyzed at high temperature to decompose large molecules into smaller hydrocarbons. Pyrolysis technology is applicable to many types of plastics, but not all kinds of waste plastic can be easily or economically converted to fuel. The feasibility depends on the plastic’s chemical composition, contamination level, and physical properties.

DOING waste plastic pyrolysis technology

DOING waste plastic pyrolysis technology

The plastics that can be converted into fuel include:

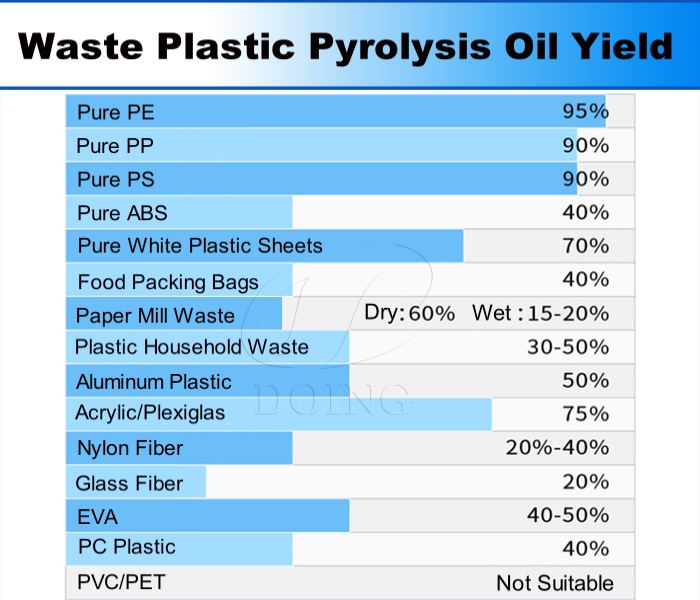

Polyethylene (PE): including high-density polyethylene (HDPE), low-density polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), Cross-Linked Polyethylene (XLPE). This type of plastic is one of the ideal raw materials for pyrolysis as oil yields can reach up to 95%. Due to the characteristics of PE plastic, pyrolysis easily produces wax oil, but DOING has achieved a breakthrough solution to this problem (Recommended Reading: How to remove wax from Polyethylene plastic pyrolysis process)

Polypropylene (PP): Similar in structure to PE, PP produces similar pyrolysis products, including a range of light and heavy hydrocarbons. Oil yield is 90%.

Polystyrene (PS): PS is easily decomposed into smaller molecules during pyrolysis, yielding a higher proportion of aromatic compounds such as benzene, toluene, and xylene. Oil yield is 90%.

Acrylonitrile Butadiene Styrene (ABS): ABS can be easily cracked into smaller hydrocarbon molecules during pyrolysis due to the presence of acrylonitrile, butadiene and styrene in its structure. Oil yield is 40%.

Waste plastic pyrolysis oil yield

Waste plastic pyrolysis oil yield

The plastics that can not be converted into fuel include:

Polyvinyl chloride (PVC): PVC will release toxic hydrogen chloride gas during pyrolysis, which is harmful to equipment and the environment. In addition, multi-layer composite plastics and plastics containing additives or pollutants may affect pyrolysis efficiency and product quality.

Polyethylene Terephthalate (PET): The products of PET pyrolysis are relatively complex and may include non-hydrocarbon compounds. PET pyrolysis mainly produces monomer components such as terephthalic acid and ethylene glycol, rather than directly generating hydrocarbons that can be used as fuel. Therefore, although PET can be processed through the pyrolysis process, it is more regarded as a recycled raw material for chemical regeneration rather than directly refining fuel.

Polyurethane (PU): PU releases toxic ammonia and aldehydes; Teflon produces lethal hydrofluoric acid (HF).

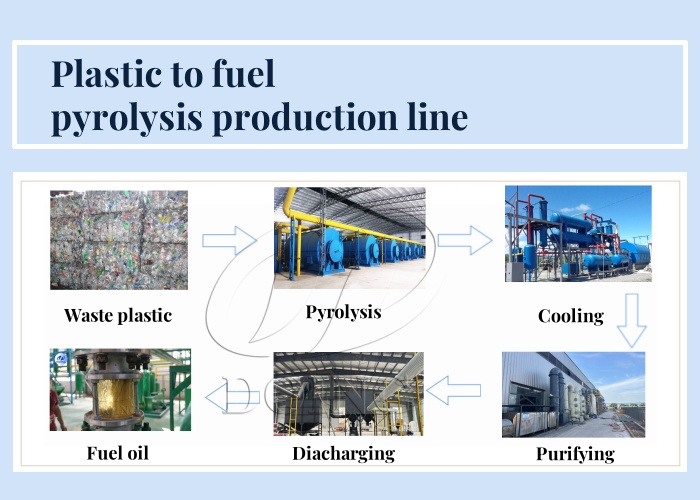

DOING waste plastic pyrolysis machine process

DOING waste plastic pyrolysis machine process

In summary, not all waste plastics are easy to convert into fuel, so it is recommended to be mindful of the type of plastic you recycle. However, mixed plastics and aluminum-plastic plastics can also be pyrolyzed into fuel. For businesses looking to turn waste plastic into profitable fuel, DOING waste plastic pyrolysis machine can maximize oil yields in an efficient and environmentally friendly way, DOING plastic pyrolysis machine has been successfully installed and operated in countries such as India, Pakistan, Thailand, Malaysia, Indonesia, Brazil, the United Kingdom, and Egypt. Welcome to consult our plastic pyrolysis machine.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.