Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

What types of feed can we use for semi-continuous pyrolysis equipment?

Semi-continuous pyrolysis equipment is an efficient and flexible solution for recycling various types of waste streams composed of hydrocarbon polymers, like tires, rubber, plastics, oil sludge, and coal tar. In order to maximize its potential and ensure smooth, profitable operation, understanding the correct feedstock is crucial. Generally speaking, semi-continuous pyrolysis equipment can process a wide variety of waste feedstocks, including but not limited to:

DOING semi-continuous pyrolysis equipment site

DOING semi-continuous pyrolysis equipment site

1.Scrap Tires and Rubber:

Scrap tires (passenger car, truck, industrial tires) and rubber waste (conveyor belts, gaskets, O-rings, rubber pads, and manufacturing scrap) are ideal feedstocks for semi-continuous pyrolysis equipment.

Product Output: Conversion into 46-50% pyrolysis oil, 40-42% carbon black, and 10-12% off-gas.

2.Plastic Waste:

Common Types: Low-Density Polyethylene (LDPE) (plastic bags, agricultural film), High-Density Polyethylene (HDPE) (bottles, crates), Polypropylene (PP) (packaging pallets, drums), Polystyrene (PS) (foam).

Mixed Plastics: Even unsorted, slightly contaminated plastics (e.g., food packaging) can be processed without strict sorting.

Product Output: Conversion into 20-80% pyrolysis oil, 15-60% carbon black, and 5-15% tail gas.

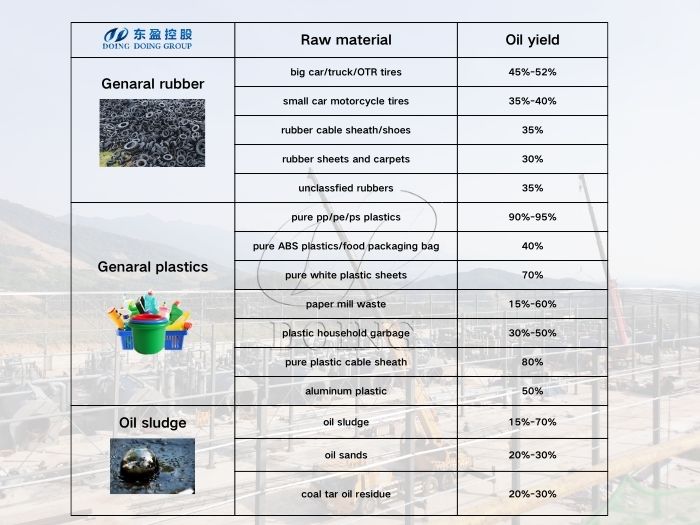

Feedstocks oil yield for semi-continuous pyrolysis equipment

Feedstocks oil yield for semi-continuous pyrolysis equipment

3.Oil Sludge and Coal Tar:

Oil sludge: Municipal/industrial sewage sludge/oil-based mud (OBM) from refineries, drilling sites, or wastewater treatment plants, containing high concentrations of crude oil and heavy metals.

Coal Tar: A byproduct of coal carbonization, rich in aromatic hydrocarbons.

Product Output: Conversion into 20-80% pyrolysis oil, 15-60% carbon black, and 2-10% tail gas.

4.Other Hydrocarbon Wastes:

Agricultural Wastes: Straw, corn cobs, rice husks

Forestry waste: Wood chips, sawdust, bark

Product Output: Conversion into 30-35% charcoal, 20-25% wood vinegar, 5-10% tar, 25-35% tail gas.

Feedstocks type for semi-continuous pyrolysis equipment

Feedstocks type for semi-continuous pyrolysis equipment

Semi-continuous pyrolysis equipment combines batch and fully continuous pyrolysis systems, using either a screw or extruder feed method. To ensure a smooth and continuous feeding process and optimize performance, the feedstock must be properly pre-treated:

1.Shredding:

The material must be shredded into small, uniform pieces to ensure a consistent and uninterrupted flow into the reactor. For instance, waste tires, plastics, and biomass should be processed into smaller than 30 mm.

2.Metal removal:

The feeding door remains sealed during operation for safety and efficiency. This means all metal must be removed before feeding. For tires, this involves removing the steel wire before the granulated rubber enters the pyrolysis reactor. Failure to do so can damage the screw mechanism and disrupt the entire

3.Drying:

Maintain a moisture content of less than 20% in the above feedstocks to prevent a drop in reactor temperature.

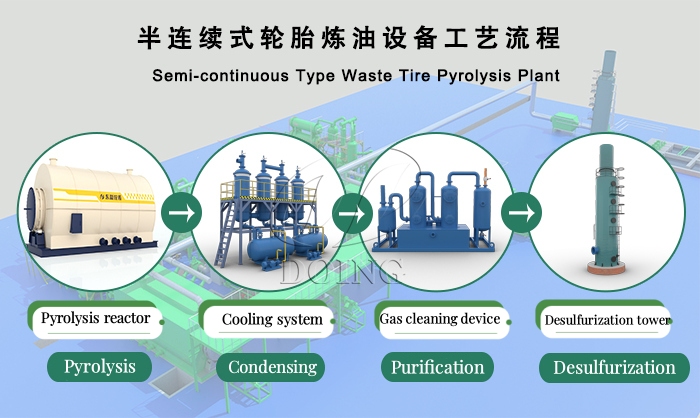

DOING semi-continuous pyrolysis equipment process

DOING semi-continuous pyrolysis equipment process

By meeting these preparation standards, you ensure the DOING semi-continuous pyrolysis equipment operates at peak performance, minimizing downtime and maintenance costs. The outputs of a semi-continuous pyrolysis equipment have a wide range of applications:

1.Pyrolysis oil (fuel oil):

A storable energy source with a calorific value of 42-45 MJ/kg. It can be used as an industrial fuel or further refined into diesel for heavy machinery or diesel generators.

2.Synthesis gas (pyrolysis gas):

A non-condensable gas that can be recycled to heat the reactor, making the system self-sufficient and reducing energy costs.

3.Carbon black:

A solid residue used as a reinforcement, pigment, or fuel in rubber products, or in construction.

4.Steel wire:

Can be recycled as scrap metal and sold directly to steel mills for reuse.

Waste to value recycling applications

Waste to value recycling applications

If you are unsure whether your waste feed is compatible, It's best to confirm your specific feedstock requirements with us first. DOING offers customized solutions from raw material pretreatment to product further processing. Send us your enquiry today to learn how our semi-continuous pyrolysis equipment can turn your waste into a revenue stream.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.