Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

15TPD waste tyre to fuel oil pyrolysis plant project site in Kenya

New customer site with on-site feedback from DOING engineer! A set of 15TPD waste tyre to fuel oil pyrolysis plant was successfully installed in Kenya. The following is the installation video of the waste tyre to fuel oil pyrolysis plant project:

The project has an annual processing capacity of approximately 5,000 tons, which can recycle waste tires into valuable final products: fuel oil, carbon black, steel wire and syn-gas. The Kenya customer has his own construction factory, which will consume lots of fuel energy for running, while the obtained fuel oil from this waste tyre to fuel oil pyrolysis plant project can make up for the relevant energy consumption and provide a more cost-effective option.

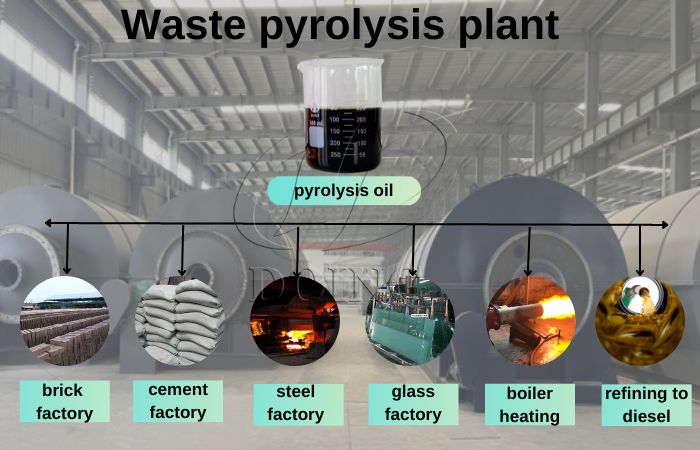

Wide applications of obtained fuel oil

Wide applications of obtained fuel oil

The 15TPD waste tyre to fuel oil pyrolysis plant ordered by the Kenya customer equips some devices to enhance the work efficiency and performance of the whole project:

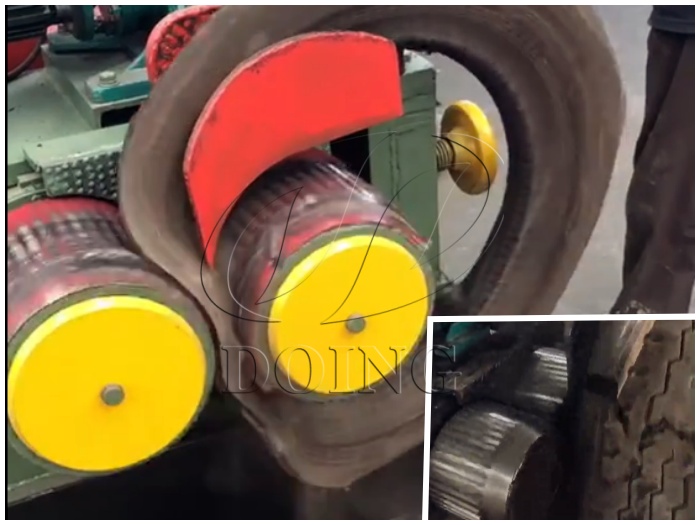

1. Waste tire pretreatment device: although the waste tyre to fuel oil pyrolysis plant can process the whole waste tires directly, but to enhance the pyrolysis efficiency and fully utilize the reactor space, this project equips the steel wire drawing machine and tire cutting machine; and to enhance the feeding efficiency, the customer also ordered a set of auto-feeding machine;

Waste tire pretreatment device

Waste tire pretreatment device

2. Safety and environmental protection device: to avoid the accident of flash-explosion, this plant equips the negative pressure vacuum device, which can fully extract the remained oil gas in the pyrolysis reactor; to meet the exhaust gas emission standard in Kenya, this plant equips the desulfurization tower and tail gas cleaning system, which can make further purification for the tail gas and exhaust gas;

DOING desulfurization tower for sale

DOING desulfurization tower for sale

3. Final product deep processing device: to enlarge the application of the obtained final by-product-carbon black, the Kenya customer ordered the Carbon black briquette machine, which can briquette carbon black into pellets, to be directly used for industrial heating instead of coal;

After signing the contract with the Kenya customer, DOING immediately sent the manufacturing notice to the factory. And about three months later, this set of 15TPD waste tyre to fuel oil pyrolysis plant was finished fabrication. After serious quality inspection and packaging, this set plant was delivered to Kenya from the DOING factory:

Delivery pictures of waste tyre pyrolysis plant to Kenya

Delivery pictures of waste tyre pyrolysis plant to Kenya

After arriving in Kenya, DOING immediately started to communicate with Kenyan customer about the installation plan. After discussion, DOING also arranged for our engineer to go to the Kenyan customer site to guide the project site planning and equipment installation, and provide relevant training and guidance to local workers on equipment operation and subsequent maintenance.

Installation site of waste tyre pyrolysis plant in Kenya

Installation site of waste tyre pyrolysis plant in Kenya

During the whole cooperation process with the Kenya customer from contract signing, equipment deliver to installation, the Kenya customer showed great satisfaction with the attitude and service of DOING Company and looking forward to cooperating with DOING for the next time.

DOING has over 14 years experience in the pyrolysis plant industry, and in addition to Kenya, DOING also cooperated with our customers in other countries, such as India, Mexico, Thailand, Ghana, Russia, America, South Africa, Vietnam, Nigeria, Malaysia, Brazil, etc. If you are interested in our machine, please directly contact us!

Get More Project Information

Please leave your contact information and details of the 15TPD waste tyre to fuel oil pyrolysis plant project site in Kenya you want to know so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications