Tyre pyrolysis process ?

Tyre pyrolysis process

Tyre pyrolysis process plant

Tyre pyrolysis process waste tyre to fuel oil and carbon black

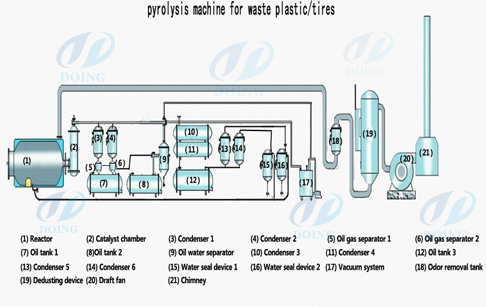

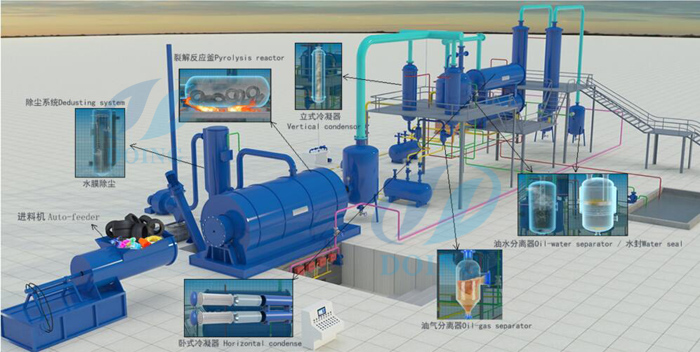

1. Feeding the raw material into the reactor by manual or auto feeder, then fire the fuel to heat the reactor.

2. After the temperature increases to relevant degree, the oil gas will be generated and enter the gas separator.

3. The heavy components will be liquefied and drop into the heavy oil tank. And light oil gas will rise into the oil condenser being liquefied and get into the oil tank.

4. The unliquefied combustible gas will enter the hydroseal , in here , after desulfuration and purification , one part of it will be recycled to heat the reactor, another part will be burn out to reduce the pressure while the pressure is too high.

When the whole process is over, we can get fuel oil, steel wire, carbon black from tyre pyrolysis plant. And they all have a wide range of applications.

Fuel Oil (40% to 45%)

Fuel oil application

Carbon Black Powder (30% to 35%)

Carbon black application

The second product of tyre pyrolysis process is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compare to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Steel Wire Scrape ( 10% TO 15% )

The third product of tyre pyrolysis process is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. Its very easy to sales steel wire scrape in local market.

Pyrolytic Gases ( About 10 % )

We get pyrolytic gases during process about 10% of waste tyre. The main component of this gases are methane ( CH4 ), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Recycling pyrolysis plant product

-

Pyrolysis plant

- Convertion of waste plastic into fuel process machine

- Tyre to oil recycling process pyrolysis plant

- Tyre derived fuel oil recycling plant

- Tyre to oil recycling process plant

- Plastic to fuel oil conversion machine

- Waste plastic tyre pyrolysis plant

- 10Ton tyre pyrolysis plant

- Waste car tyre recycling pyrolysis plant

- Waste tyre pyrolysis process plant

- Plastic waste recycling process pyrolysis plant

-

Recycling machine

- Tire to oil recycling machine

- Waste tyre to oil recycling plant

- Latest Generation Tyre Pyrolysis Plant

- Waste tyre recycling plant price

- Recycling plastic bottles to fuel oil machine

- Pyrolysis tire recycling system

- Used tyre recycling machine

- Waste recycling pyrolysis plant

- 10Ton tyre to oil recycling pyrolysis plant

- Recycling plastic bags to oil machine

-

Waste to energy plant

- Waste tyres oil extraction plant to get diesel oil

- Waste oil to diesel equipment

- Straw biomass pyrolysis equipment power generation industry

- Plastic to oil pyrolysis plant

- Waste tyre to fuel oil energy machine

- DOING waste to energy (WTE) recycling pyrolysis machines

- Waste engine oil/waste oil purification industry

- Waste tyre pyrolysis industry

- Waste tyre to crude oil plant

- Waste to oil energy pyrolysis plant

-

Waste oil refinery machine

- Turn plastic into diesel plant

- Crude oil distillation process machine

- Waste tyre converted into diesel plant

- Waste oil distillation to diesel plant

- Tire oil to diesel refining machine

- Convert waste engine oil to diesel machine

- Machine to recycle motor oil into diesel

- Waste engine oil distillation machine

- Crude oil refinery plant manufacturers

- Tyre oil to diesel refining plant

-

Plastic to oil

- Machine that turns plastic back into oil

- Plastic recycling to fuel oil plant

- Waste Management of Waste plastic to oil machine

- Green tech waste plastic pyrolysis plant to get fuel oil

- Machine to convert plastic into oil

- Waste plastic pyrolysis to fuel oil plant

- Plastic to oil conversion machine

- Waste plstic to oil plant

- Convert plastic to oil machine

- Continuous process of plastic into oil machine

-

Tire to oil

- Furnace oil from used tyres machine

- Waste tyre pyrolysis to oil plant

- Tire to oil machine

- Newest old tyres to oil pyrolysis technology

- The 6th generation turn waste tyre to oil equipment

- DOING tyre to oil pyrolysis plant

- Recycling tire into oil plant

- Furnace oil from waste tyres

- 5th generation waste tyre to oil recycling machine

- Waste tyre to oil plant

-

Auxilary equipment

- Auto-feeder for waste tire recycling machine

- Tyre doubling machine for waste tyre pyrolysis plant

- Tire Cutting Strips Machine

- Auto-feeder for plastic to oil machine

- Carbon black pellet machine for pyrolysis plant

- Tire Cutting Block Machine

- Hydraulic Tire Cutting Machine

- Waste Tyre Circle Cutting Machine for pyrolysis machine

- DOING waste tyre doubling machine for sale

- Carbon Black Raymond Mill

Contact Us

FAQ Products

- Other uses for diesel fuel?

- Uses and application of crude oil?

- How long is the pyrolysis plants' reactor service life?

- Wheather DOING company send expert to guide install pyrolysis plant?

- Why we need pyrolysis plant?

- What is waste to energy technology?

- Tyre pyrolysis oil use?

- Continuous plastic pyrolysis plant working process?

- What is the application of raw carbon black?

- Plastic to diesel process ?

RELATED EQUIPMENT

RELATED EQUIPMENT