Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

What systems are needed to recycle waste tires to oil in fully continuous waste tire pyrolysis production line?

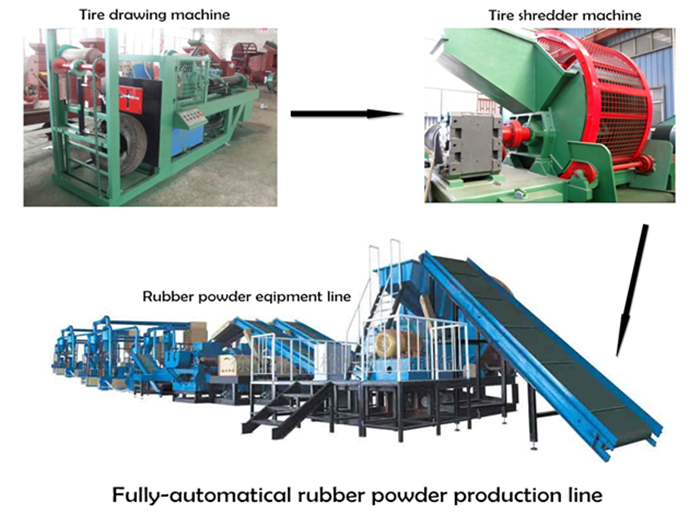

1. Tire pretreatment system.

Full-continuous pyrolysis machine has strict requirements on the size of the feed material. If the tire is processed, it needs to be broken into rubber powder, because not only the thick steel wire must be removed, but also the capillary steel wire must be magnetically separated to blockage during operation.

Fully automatic rubber powder production line

Fully automatic rubber powder production line

2.Automatic feeding system.

First, the rubber powder in the storage tank is pushed into the reactor through two automatic feeding augers to ensure that the material is fed in a sealed condition. The length of the reactor is 26 meters. Our continuous pyrolysis machine is designed with accurate calculations. The length of the reactor can ensure that the raw materials are fully pyrolysised. Because the reactor is too long, which brings difficulties to transportation and installation, so the reactor is divided into two parts, and the reactor is dragged by three groups of tugs to rotate at a uniform speed to achieve uniform heating.

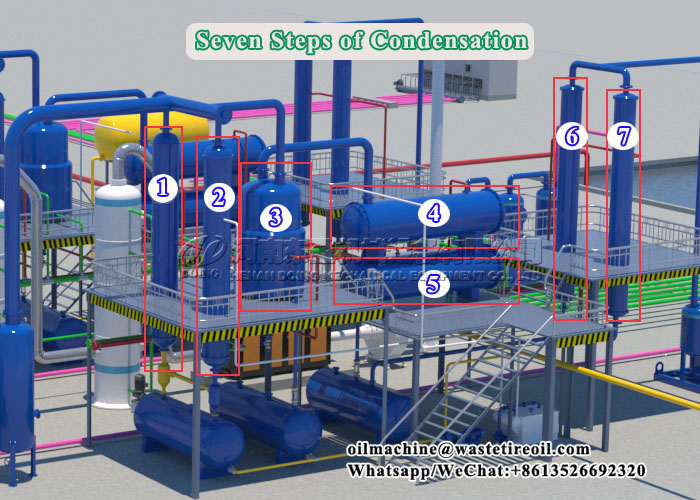

3.Condensation system.

The produced oil gas pass through two buffer tanks to buffer the oil gas flow rate and filter impurities. The oil gas will continue to be cooled by four vertical condensers connected in series. After the oil gas are cooled, the cooled oil is collected into temporary storage tanks.

Condensation system of pyrolysis plant

Condensation system of pyrolysis plant

4.Slag discharge system.

Full continuous pyrolysis machine can achieve full continuous running is not only to achieve continuous feeding, but also to achieve continuous slagging.The produced carbon black will be discharged into the fixed section slagging auger.The last two slagging augers are equipped with cold water jackets. Circulating water is used to cool the carbon black, and the temperature of the carbon black will eventually be cooled to about 50 degrees and collected in the carbon black packing bag.

Slag discharge system

Slag discharge system

These above systems are needed to recycle waste tires to oil in fully continuous waste tire pyrolysis production line.If you have any questions ,please contact us for free.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications