Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Is turning plastic into fuel by pyrolysis devices profitable?

As plastic scrap piled up, the call for waste plastic recycling has become louder and louder. In this context, plastic to fuel pyrolysis devices emerged. This article will evaluate the economic feasibility and profitability of the plastic to fuel pyrolysis device from four aspects: market analysis, process flow diagram and design specifications, financial evaluation and sensitivity analysis.

Waste plastic to fuel conversation

Waste plastic to fuel conversation

1. Market analysis

According to statistics, more than 300 million tons of plastic waste are produced globally every year, of which less than 10% is recycled and most of it is landfilled or incinerated, which will pollute the land, make more pollution. The plastic to fuel pyrolysis device can convert waste plastic into renewable fuel, solving the problem of recycling waste plastic. Therefore, there is a huge market demand for plastic fuel conversion devices, especially in Europe, North America and Southeast Asia.

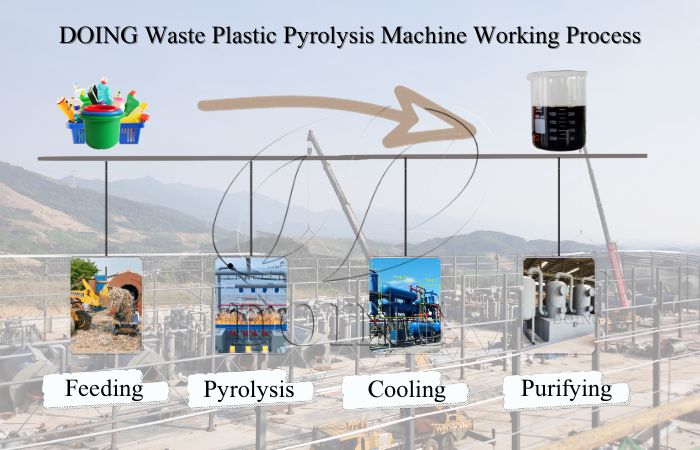

2. Process flow diagrams and design specifications

DOING GROUP has relative mature technology of pyrolysis device to recycle plastic into fuel oil. In terms of process flow, the plastic to fuel pyrolysis device cracks waste plastics into low-carbon hydrocarbons through high temperature and high pressure, and finally converts them into renewable fuels after condensation, separation, and other processes. In terms of design, plastic fuel conversion devices need to have characteristics such as stability, corrosion resistance, and high efficiency to ensure that the renewable fuel produced is of reliable quality and more sustainable.

Waste plastic to fuel pyrolysis process flow

Waste plastic to fuel pyrolysis process flow

3. Financial evaluation

The investment cost of plastic to fuel pyrolysis device will vary a lot according to the machine scale and cvonfigfuration, starting with USD20,000+ to UDS600,000+. But with the increase in market demand and continuous technological innovation, its business prospects are very broad, and you can get a fast investment payback.

By running DOING pyrolysis devices with different temperature and different kinds of waste plastic, generally you can get following products: plastic pyrolysis oil and carbon black, which had wide sales market.

Applications of plastic to fuel pyrolysis devices

Applications of plastic to fuel pyrolysis devices

4. Sensitivity analysis

When making investment decisions, in addition to considering market demand and investment costs, sensitivity risks must also be taken into consideration. For example, raw material price fluctuations, policy changes, technical difficulties and other factors will have an impact on the economic benefits of plastic fuel pyrolysis devices. Therefore, it is necessary to establish a sensitivity analysis model to evaluate and adjust investment strategies in a timely manner. In general, many countries support the environmental recycling and treatment of waste plastic. So you can invest in plastic pyrolysis to fuel business, just to select a high quality and environmental plastic to fuel pyrolysis device from professional manufacturer.

Tire plastic to fuel pyrolysis plant projects

Tire plastic to fuel pyrolysis plant projects

In summary, plastic to fuel pyrolysis devices have huge market demand and commercial prospects. In the future, plastic to fuel pyrolysis devices will be more widely used and promoted. If you have business to invest in plastic to fuel pyrolysis business, please feel free to leave a message.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.