Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Is plastic pyrolysis plant sustainable?

Plastic pyrolysis plant has become more popular in recent years, because pyrolysis waste plastic into fuel oil is considered sustainable due to its environmental impact, energy efficiency, and economic ability.

Here are some reasons why plastic pyrolysis plants got so much attention:

1. Environmental Impact: With the increasing global plastic pollution problem, there's growing interest in finding sustainable solutions for plastic waste management. Pyrolysis offers a way to convert plastic waste into valuable products, thereby reducing the reliance on landfills and incineration. Almost all the plastic waste except PVC and PET, like medical waste plastic, HDPE, LDPE, PP, PS, ABS, paper mill waste, agricultural films, vehicle bumper, mixed plastic, etc., can be recycled by plastic pyrolysis plants.

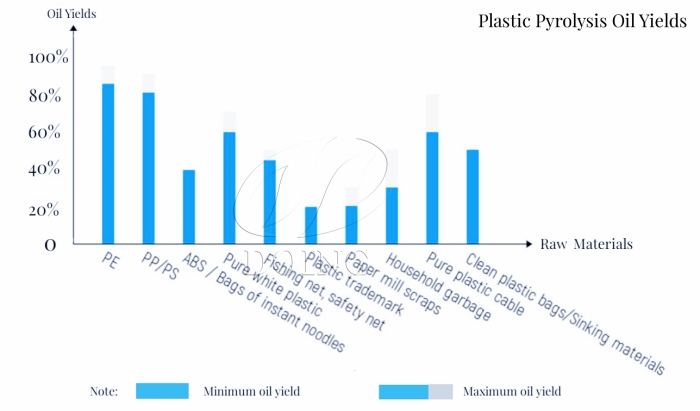

Waste plastic oil pyrolysis plant oil yields

Waste plastic oil pyrolysis plant oil yields

And during the plastic to fuel oil pyrolysis process, there is almost no waste water pollution. DOING waste plastic pyrolysis plant is also equipped with the exhaust gas purification system, which is in line with environmental emission standards.

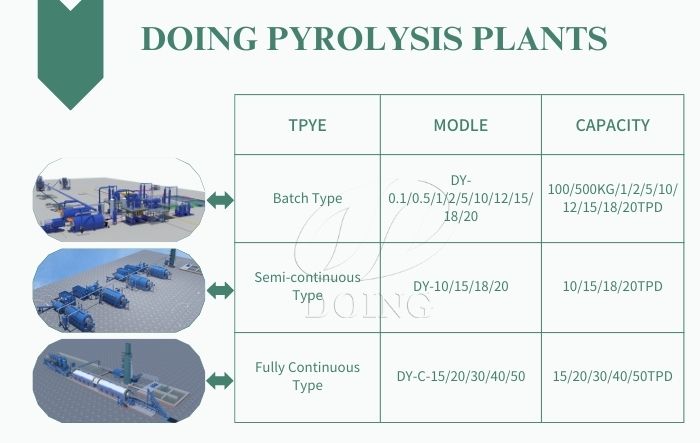

2. Energy Efficiency: plastic pyrolysis plant can maximize energy efficiency can help reduce the overall environmental footprint of the process and improve its sustainability. Take Henna Doing Company's plastic pyrolysis plant as an example, the daily capacity of each set ranges from 100kg to 50Tons per day. And we have designs of multiple plastic pyrolysis production lines. No matter the mini small scale plastic pyrolysis plant or big scale plastic pyrolysis plant, they all have energy saving design and good pyrolysis effect, which can help you turn waste plastic into fuel oil energy, achieving efficient and sustainable waste management and recovery.

DOING plastic pyrolysis plant processing capacity parameter

DOING plastic pyrolysis plant processing capacity parameter

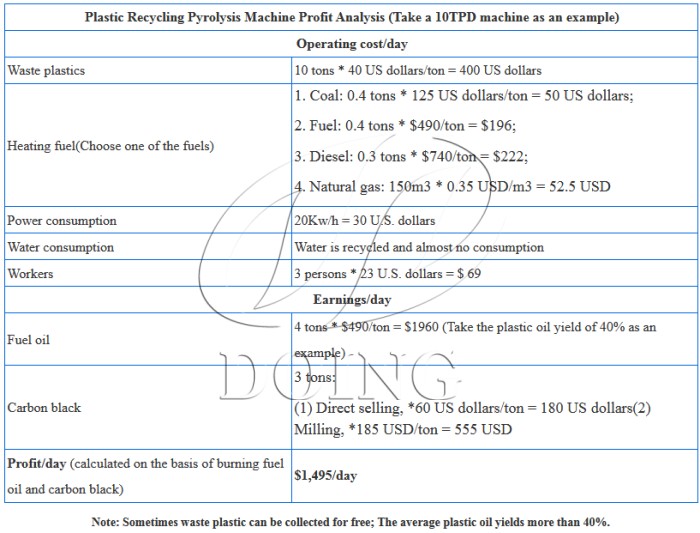

3. Economic Viability: Plastic pyrolysis can be economically viable because it generates valuable products such as fuel oil, carbon black, and syn-gas, which can be sold or used as feedstock for other processes. This resource recovery aspect makes pyrolysis attractive from both environmental and economic perspectives.

Applications of waste plastic pyrolysis plant final products

Applications of waste plastic pyrolysis plant final products

However, the economics of pyrolysis depend on factors such as feedstock availability, market demand for the end products, and operating costs. Government incentives, regulations, and policies related to waste management and renewable energy can also influence the economic viability of plastic pyrolysis projects.

4. Policy Drivers: Governments and regulatory bodies are increasingly implementing policies and regulations to promote recycling, waste-to-energy, and circular economy initiatives. This regulatory support provides incentives for investment in waste plastic to oil pyrolysis projects and contributes to its growing popularity.

Waste plastic pyrolysis plant profit analysis picture

Waste plastic pyrolysis plant profit analysis picture

Overall, plastic pyrolysis plastic holds promise as a sustainable solution for plastic waste management. If you want to engage in suitable waste plastic to fuel oil recycling and pyrolysis business, welcome to contact Henan Doing company for customizing solutions to ensure its long-term viability and effectiveness in plastic pyrolysis plant.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.