Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

8 Things to consider while selecting Pyrolysis Plant Supplier

-

Certified

- ISO Certified organisation

- CE Certified to manufacture Pyrolysis plant

-

Professional and Structured Company:

- Design engineering department

- Mechanical engineering department Electrical and automation department

- Project management team

- Installation and commissioning engineers

- Quality Control department

- Customer care and safe service department

- Tech Support

-

Authentic and pioneered technology:

- Check and verify if technology is owned or copied from someone else

- Copy of any machine or technology is never perfect

- Must own at least 2 pilot plants for developmental studies of pyrolysis

-

After Sales Support:

- Spare parts

- Telephonic guidance & Tech Support department

- Service by visit of technicians

- Operating manual

-

Visit to an operational pyrolysis plant:During visit verification of:

- Scope of supply

- Design calculations like:

- Mass and energy balance

- Energy efficiency

- Scrubbing and emission

- Payback calculations

-

Not a "One Man Show":

- There are at least 10 Employees in company (other than owner of company) who can:

- Answer to any queries about Pyrolysis Plant

- Know how to operate and maintain the plant

- Guide you before and after installation of machinery

-

No history of:

- Fire accidents

- Explosion or blast

- Loss of life or serious injuries to operators / supervisors

- Emission of black smoke and / or smell of chemical near the plant

- Closure notice by Pollution Control Board

- Discharge of hazardous effluent

-

Discuss design calculations of:

- Equipment design, Heating system design, Pollution control equipment

- Appropriate Catalyst technology

- Temperature and pressure control calculations

- Heat Transfer ad Energy Conservation

- Mass and Energy Balance

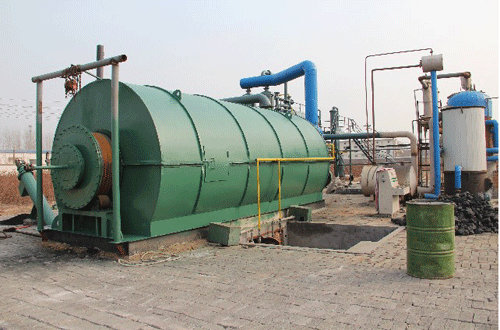

Pyrolysis plant

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.