Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Sustainable waste oil tank fuel sludge treatment way

Waste oil tank fuel sludge is a complex substance composed of waste oil, sewage and solid waste. It has complex composition, high water content and serious pollution. Traditional oil sludge treatment methods, such as landfill and incineration, not only have environmental pollution risks, but also high costs. As a new treatment method, oil sludge pyrolysis technology can not only effectively solve the problem of oil sludge pollution, but also bring certain economic benefits.

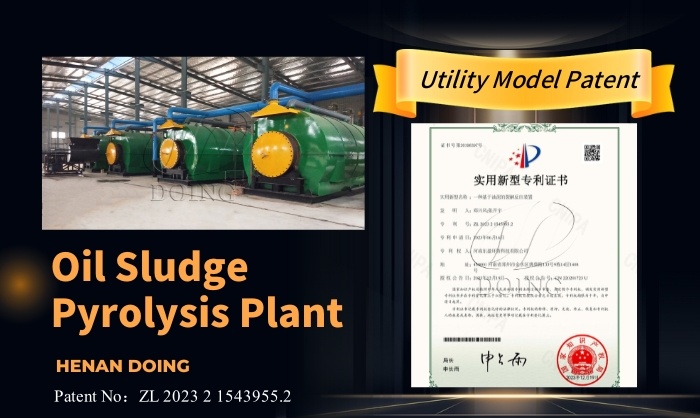

DOING oil sludge treatment pyrolysis technology

DOING oil sludge treatment pyrolysis technology

Principle of Waste Oil Tank Fuel Sludge Pyrolysis Technology

Waste oil sludge pyrolysis technology is a process of high-temperature treatment of oil tank fuel sludge under anaerobic or anoxic conditions. During the pyrolysis process, the organic matter in the oil tank fuel sludge is decomposed into products of different phases, combustible gas, liquid product (pyrolysis oil) and solid residue (soil). By recycling these products, the resource utilization of oil sludge can be realized.

Oil sludge treatment pyrolysis machine recovered products

Oil sludge treatment pyrolysis machine recovered products

Economic Benefit Analysis of Oil Sludge Pyrolysis Treatment

The economic benefits of sludge pyrolysis treatment depend on many factors, such as the composition of sludge, pyrolysis process, product recovery rate and local market price. Generally speaking, the sales revenue of sludge pyrolysis treatment is as high as thousands of dollars per ton. Therefore, sludge pyrolysis treatment can achieve certain economic benefits.

1. Recycling of Combustible Gas

The main components of the combustible gas produced during the pyrolysis process are methane, ethane, propane, etc., which have a high calorific value. It is often used as oil sludge pyrolysis reactor heating fuel, reducing energy costs.

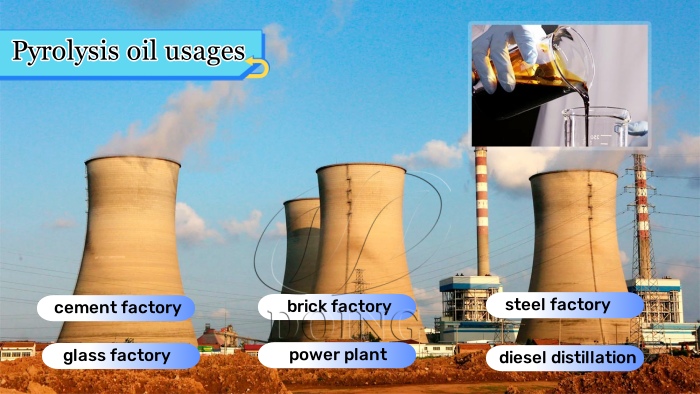

2. Applications of pyrolysis oil

Pyrolysis oil extracted from oil sludge treatment pyrolysis machine is a high-calorific value macromolecular hydrocarbon liquid fuel with a calorific value of up to 30-40MJ/kg. It can be used as boiler fuel, furnace fuel or other industrial heating fuels. Through the recycling of pyrolysis oil, the secondary energy utilization of waste oil tank fuel sludge can be realized to create economic value.

Oil sludge treatment pyrolysis oil applications

Oil sludge treatment pyrolysis oil applications

3. Treatment subsidy

As a hazardous waste, some countries like China will give certain policy subsidies for the resource utilization and treatment of related wastes.

The oil sludge pyrolysis technology has been more and more widely used because it can recover petroleum resources like waste oil tank fuel sludge and has less secondary pollution. Henan DOING Company supplies high quality oil sludge treatment pyrolysis machines for sale with mature technology to help you achieve sustainable waste oil sludge disposal. Our sales manager and engineer team sincerely welcome your inquiry!

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.