Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 12-31

How to set up a tire recycling pyrolysis plant?

- 12-26

How to avoid waste tire pyrolysis pollution environment?

- 12-11

What raw materials are suitable for the pyrolysis plant? What is the oil yield?

- 12-09

How to convert waste motor oil to diesel oil?

- 06-05

How much does a waste tyre pyrolysis plant cost?

- 04-25

How is continuous plastic pyrolysis plant working process?

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

The oil sludge pyrolysis plant is the most ideal equipment to treat the oil sludge and reuse the crude oil in the sludge. Oil sludge is a by-product of the exploration, drilling, storage, and refining of petroleum resources. It is mainly composed of crude oil, water, sludge and so on. If not treated effectively, the oil sludge will cause great pollution to the environment. And because there is so much oil in the sludge, some investors are finding opportunities. They are eager to find environmentally friendly ways to dispose of oil sludge that will benefit them. DOING oil sludge pyrolysis plant will be their most sensible choice.

Environmental pollution caused by oil sludge

Environmental pollution caused by oil sludge

DOING company's oil sludge pyrolysis plant adopts the most advanced pyrolysis technology to extract high-quality fuel oil from the oil sludge. This way not only solves the pollution caused by the oil sludge to the environment, but also the fuel oil obtained from the oil sludge can bring rich economic benefits for investors. In addition, some countries and regions have government subsidies for companies or individuals dealing with oil sludge. This has also prompted some investors to turn to oil sludge treatment projects.

DOING company's oil sludge pyrolysis plant

DOING company's oil sludge pyrolysis plant

In order to meet the needs of different customers, we have designed different types of oil sludge pyrolysis plant. The following are the specific parameters of several devices. If you have special requirements, we can also design and produce according to your specific requirements.

|

No. |

Items |

Contents |

||

|

1 |

Equipment type |

DY-1-6 |

DY-1-10 |

DY-1-12 |

|

2 |

Raw material |

Waste tyre |

Waste tyre |

Waste tyre |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

10 ton |

12 ton |

|

5 |

Oil yield |

2.7-3.3ton |

4.5-5.5ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2600×6600 |

2800×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

32T |

35T |

The oil sludge pyrolysis plant produced by DOING company mainly consists of screw feeder, pyrolysis reactor, condenser, oil-gas separator, water seal, negative pressure system and exhaust gas purification system. In order to control the operation and safety, our equipment is designed with control cabinet and automatic alarm device, so as to control the operation and prevent the occurrence of some misoperation.

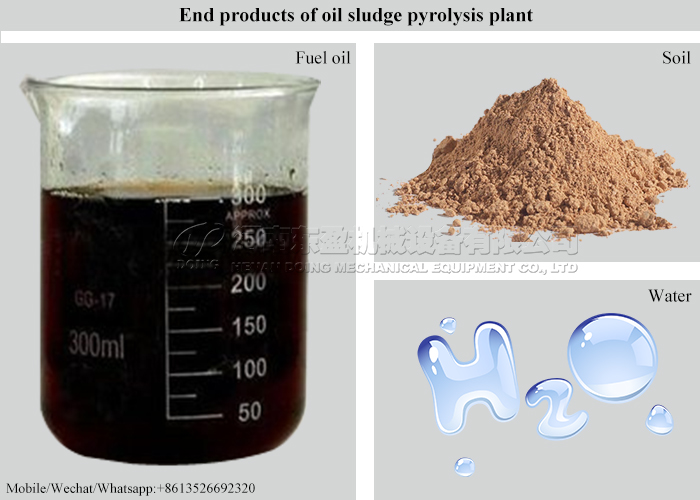

End products of oil sludge pyrolysis plant

End products of oil sludge pyrolysis plant

End products of oil sludge pyrolysis plant

1. Fuel oil

The fuel oil is of high quality. It can be used directly as a fuel, of course, you can also use waste oil refining equipment to refine it into diesel;

2. Solid waste

Solid waste can be used to make bricks for buildings or to pave roads.

The unique advantages of DOING oil sludge pyrolysis plant are as follows

1. The heating system of DOING oil sludge pyrolysis plant can use a variety of fuels, such as fuel oil, fuel gas, coal, wood, etc., and can also directly use combustible gas generated in the pyrolysis process to reduce the cost;

2. It can handle a wide range of raw materials. In addition to oil sludge, it can deal with the life of waste tires, waste plastic, waste rubber and other organic matter;

3. It equipped with exhaust gas purification system, water seal, etc., the whole production process is ecologically friendly, with emissions up to eu environmental standards;

3. DOING oil sludge pyrolysis plant adopts the most advanced pyrolysis technology and high-quality equipment to manufacture materials to improve the output and quality of oil products and extend the service life of pyrolysis reactor;

DOING company

DOING company

DOING company has 10 years of rich experience in this field. As a professional machinery supplier, we can provide customized service, not only has a full set of service system, from the early stage of the consultation, to the device, the choice of configuration, equipment installation, equipment operation of technical training and equipment maintenance, etc., in the late we have professional personnel tracking service.

Request a Quote for the Oil Sludge Pyrolysis Plant

Please leave your contact information and Oil Sludge Pyrolysis Plant requirements so that our professional team can contact you as soon as possible.