Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

How is continuous plastic pyrolysis plant working process?

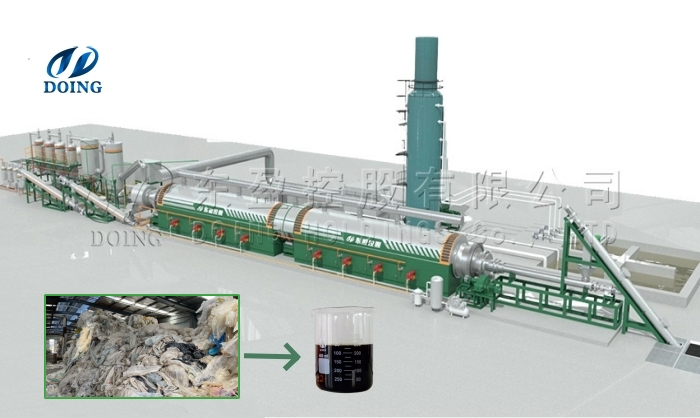

The continuous plastic pyrolysis plant represents a technological advancement over traditional batch-type pyrolysis systems, offering higher automation, efficiency, and environmental safety. This system converts waste plastic into valuable fuel oil, carbon black, and combustible gas through a sealed, pollution-free process. The main working process of continuous plastic pyrolysis plant includes: raw material pretreatment - feeding - heating - cooling - slag discharge - waste gas recovery and treatment.

Continuous plasic to oil and carbon black pyrolysis plant

Continuous plasic to oil and carbon black pyrolysis plant

Here's a step-by-step breakdown of continuous plastic pyrolysis plant working process:

1. Raw Material Pretreatment

Plastic Selection: The plant processes mixed plastics (PP, PE, PS, ABS, etc.), excluding PVC and PET ( due to chlorine emissions and less oil yield).

Preprocessing: A crusher or shredder breaks down bulk plastics into small, uniform particles (usually less than 5mm) for smoother feeding and faster pyrolysis.

Optional Dehydration: Wet plastics may require drying to reduce energy consumption during pyrolysis, and the water content is controlled below 3%.

2. Automatic Feeding

Preprocessed plastic particles are continuously fed into the reactor via an enclosed screw conveyor, ensuring zero gas leakage and steady processing capacity.

Continuous plastic pyrolysis plant working process

Continuous plastic pyrolysis plant working process

3. Heating and High-Temperature Pyrolysis

The continuous plastic pyrolysis plant reactor will be heated to 350–500°C in an oxygen-free environment, breaking waste plastic polymer chains into:

Oil gas (condensed into fuel oil)

Carbon black (solid byproduct)

Non-condensable gas (recycled as reactor fuel)

Temperature control: A PLC system adjusts heating to maximize oil yield and minimize residue.

4. Gas Cooling & Oil Liquefaction

Hot oil gas passes through a multi-stage condenser (vertical/horizontal) and is cooled into liquid fuel oil.

5. Automated Slag Discharge

Residual pyrolysis carbon black(RCB recovered carbon black) is automatically discharged into a sealed collection tank via a sealed discharging mechanism. This ensures a continuous operation without the need for manual intervention and further minimizes environmental exposure.

6. Waste gas recovery and treatment

Non-condensable gas utilization: Some non-condensable gas is produced during pyrolysis. This gas can be recovered and reused to heat the pyrolysis reactor, reducing fuel costs and enhancing the plant's energy efficiency.

Exhaust gas treatment: Exhaust gases generated during the heating process are treated by tail gas cleaning systems, potentially including deodorization, desulfurization, and particulate removal, to meet environmental standards and reduce pollution.

Products of the continuous plastic pyrolysis process

Fuel Oil/Pyrolysis Oil: This liquid fuel can be directly used as fuel in industrial furnaces, boilers, or cement kilns, providing a sustainable energy source.

Waste plastic pyrolysis oil and carbon black applications

Waste plastic pyrolysis oil and carbon black applications

Carbon Black: It has extensive use in the manufacturing of tires, rubber products, pigments, inks, plastics, and coatings. Its properties enhance durability, strength, and conductivity in various end products.

Non-condensable Gases:These gases can be captured and utilized as a supplementary fuel source to preheat the incoming feedstock or to power the plant’s heating system.

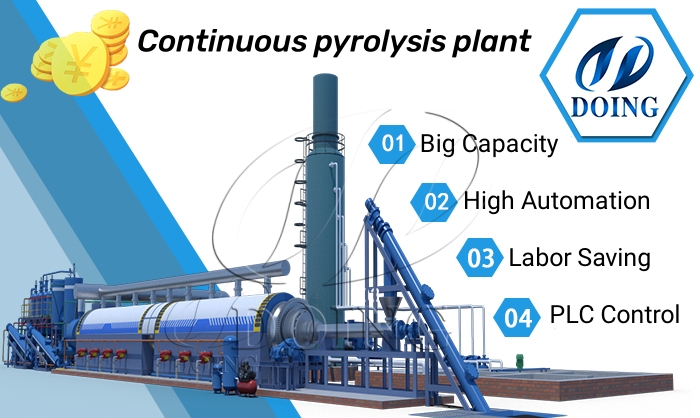

Advantages of Continuous Plastic Pyrolysis Plants

The adoption of a continuous plastic pyrolysis plant offers distinct advantages over its batch pyrolysis machines:

24/7 Operation: No need for cooling/reheating between batches, doubling/tripling efficiency vs. batch pyrolysis plants.

Higher Oil Output and Consistent Product Quality: Optimized temperature control and stable operating conditions inherent in a continuous process lead to more consistent quality of the produced fuel oil and carbon black.

Continuous plastic pyrolysis plant advantages

Continuous plastic pyrolysis plant advantages

Environmental Friendliness: The sealed and controlled nature of the process ensures minimal emissions, contributing to a cleaner and more sustainable waste management solution, effectively reducing carbon footprints.

Lower Labor Costs: PLC automation reduces manual intervention, leading to a safer and more streamlined operation.

Scalability: Modular continuous plastic pyrolysis plant designs support 15–50 TPD capacity per set for large-scale/industrial scale waste plastic treatment and recycling.

Is your company seeking an advanced solution for plastic waste management and resource recovery? If you have any questions about the working process of a continuous plastic pyrolysis plant, its specific applications, or how it can benefit your operations, please leave a message on our website. The professional project engineers at DOING Company are ready to provide you with a comprehensive and satisfactory answer. Let’s explore how our leading pyrolysis technology can transform your waste into valuable resources.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.