Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Alternative Fuel Oil for Cement Industry: Pyrolysis Oil

In an era where sustainability and resource efficiency are at the forefront of industrial advancements, the cement industry stands as a significant player with considerable room for innovation. Traditional fossil fuels used in cement production are increasingly scrutinized for their environmental impact, pushing the industry to explore alternative fuels. Among these, pyrolysis oil emerges as a compelling option, offering both economic and ecological benefits.

Cement industry alternative fuel pyrolysis oil applications

Cement industry alternative fuel pyrolysis oil applications

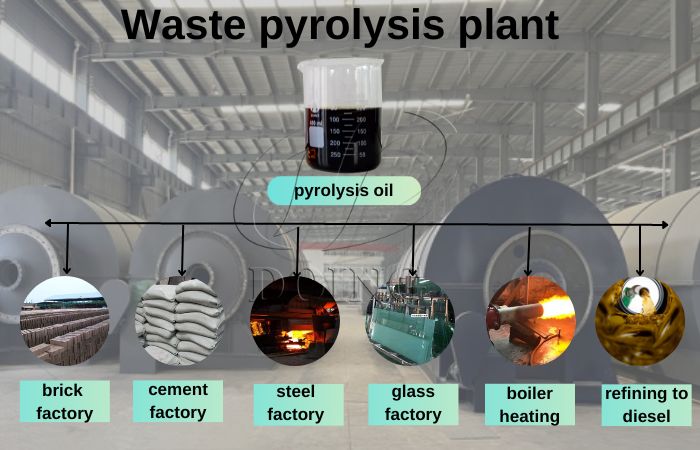

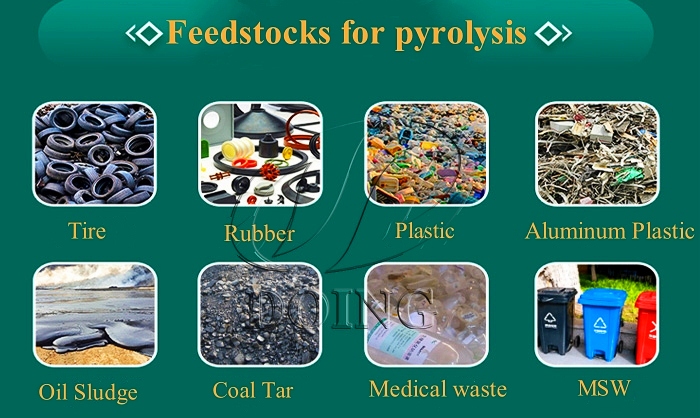

What is Pyrolysis Oil?

Pyrolysis oil, is derived from the thermal decomposition of organic materials in the absence of oxygen—a process called pyrolysis. This pyrolysis system converts municipal solid hazardous waste such as waste rubber tire, plastic, oil sludge, etc. into a liquid fuel that can be used as a substitute for conventional fossil fuels. With the heating value 10592.48Kcal/Kg, this fuel oil is a kind of good heating fuel which can be applied for boiler factory, cement factory, glass factory and steel mill, etc.

The whole pyrolysis oil production process involves heating the waste materials to high temperatures, breaking it down into oil gas, which are then condensed into a liquid form.

Waste raw materials pyrolysis oil production system

Waste raw materials pyrolysis oil production system

Why Pyrolysis Oil for Cement Production?

1. Environmental Benefits

Pyrolysis oil is a cleaner alternative to traditional fossil fuels, significantly reducing greenhouse gas emissions. By using pyrolysis oil, cement manufacturers can lower their carbon footprint, helping to meet stringent environmental regulations and contribute to global sustainability goals.

2.Waste Management

The use of waste materials for pyrolysis oil production addresses two critical issues simultaneously: waste disposal and energy production. This not only reduces landfill waste but also converts otherwise discarded materials into valuable energy sources.

Waste raw materials for pyrolysis oil

Waste raw materials for pyrolysis oil

3. Economic Advantages

Investing in pyrolysis oil technology can be economically advantageous for cement plants. The cost of pyrolysis oil can be competitive with, or even lower than, traditional fossil fuels, depending on local waste availability and production scale. Additionally, the rise in waste disposal costs can be mitigated through the sale of pyrolysis oil.

4. Energy Efficiency

Pyrolysis oil boasts a high energy content, making it an effective fuel for cement kilns or other smiliar heavy industries, like steel factories, brick factories, glass factories, etc. Its properties are well-suited to the high-temperature requirements of cement production, ensuring that the energy needs of the process are met efficiently.

Investing in Pyrolysis Oil Production Business

The shift towards pyrolysis oil not only benefits cement producers but also creates a burgeoning market for pyrolysis technology and equipment. Investing in pyrolysis oil production facilities presents a lucrative business opportunity. Companies specializing in pyrolysis technology are developing advanced systems that are increasingly efficient and cost-effective.

1. Technology and Equipment

Modern pyrolysis systems are designed to maximize yield and efficiency. Advanced systems offer improved feedstock handling, optimized reaction conditions, and enhanced oil quality. Investing in state-of-the-art pyrolysis system ensures higher productivity and better fuel quality, crucial for meeting the demanding energy needs of cement production.

Reliable pyrolysis system manufacturer and supplier

Reliable pyrolysis system manufacturer and supplier

2. Market Potential

As global industries and governments focus more on reducing carbon footprints, the demand for alternative fuels like pyrolysis oil is expected to grow.

3. Regulatory Support

Many regions are offering incentives and subsidies for companies adopting green technologies, including alternative fuels. This regulatory support can help offset initial investment costs and encourage further development in pyrolysis oil production.

Pyrolysis oil represents a promising alternative fuel for the cement industry, aligning with global sustainability trends and addressing key environmental and economic challenges. For businesses involved in the cement sector or pyrolysis technology, this is an opportune moment to explore and invest in pyrolysis oil production. By embracing this innovative fuel, companies not only advance their development while capitalizing on a growing market opportunity.

Pyrolysis oil production from DOING pyrolysis system

Pyrolysis oil production from DOING pyrolysis system

As a professional and reliable manufacturer of pyrolysis systems, we Henan Doing Company has helped many customers develop the pyrolysis oil production business. If you also want to build your own pyrolysis plant, we can offer you all-around services.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.