Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

A new way to disposal waste tires by waste tire recycling to diesel machine

A new way to disposal waste tyres by waste tire recycling to diesel machine:

According to the 2010 Greendex report by the National Geographic Society and the international polling firm GlobeScan, Brazil is ranked the second regarding concern of sustainable consumption in the world, only trailing India. According to the official statistics, it shows that 250,000 unserviceable tires were collected in 2009. The waste tires can be transformed into asphalt, shoes, ducts, floors, carpets, and even alternative tire fuel oil. But when they’re not recycled, the tires are disposed into dump sites and cause great harm to the environment. Can you imagine that it takes up to 150 years to decompose the waste tire? It is definitely necessary to ensure that these tires end up being recycled andn disposed properly. Here I will introduce you a good way for waste tire management, the waste tire recycling to diesel, turn waste to energy and create profits, we have no reason to refuse it.

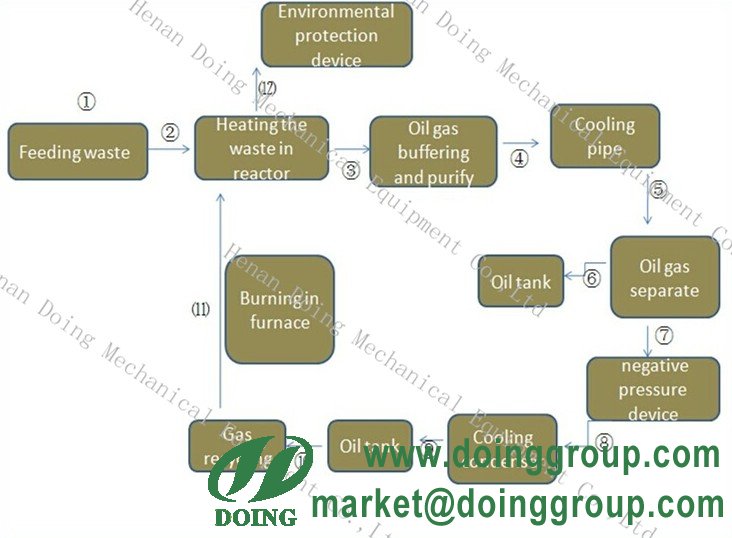

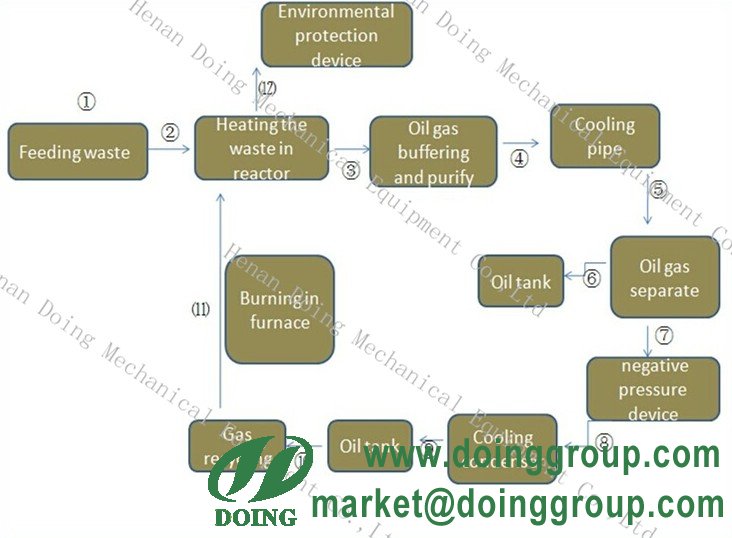

New way to disposal waste tires by waste tire to diesel machine

Why waste tire can be recycling to diesel fuel?

Tire components: A tire is made of natural rubber (also named as virgin rubber), Styrene-Butadiene(SBR), Polybutadiene Rubber(PBR), Carbon Black, Nylon tire cord, rubber chemicals, steel tire cord and Butyl rubber. The waste tire recycling to diesel process is the decomposition of tire polymer since waste tires are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross link or straight chain. During high temperature pyrolysis processing, the long chain( C-50000 to C-200000) in tire was broken down into smaller chains (C-1 to C-4 & C-5 to C-23). Among these elements, C5-C23 is oil polymer got from tire long chain polymer.

Waste tire disposal

Final products of waste tire recycling to diesel and usage:

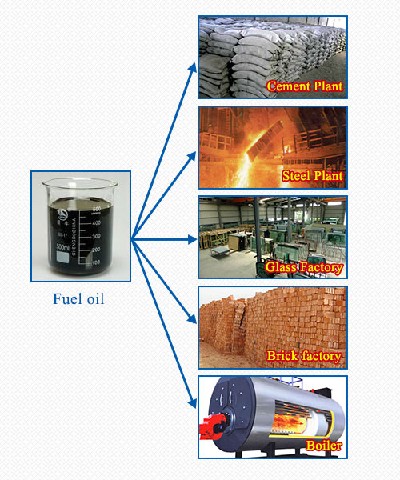

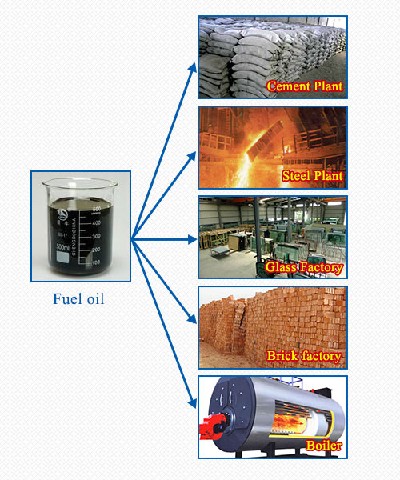

1. FUEL OIL (45% to 50%)

The main product generated by our waste tire recycling to diesel plant is fuel oil which is widely used in industrial field so that has great commercial benefits. The oil has 45% to 50% yield of the amount of recycled scrap tyres, which can be used in power plant factory, glass factory, cement factory, ceramic factory, aluminum factory, boiler factory, central heating factory etc.

2. CARBON BLACK (30% to 35%)

Carbon black produced by waste tire recycling to diesel plant is more economical compared to carbon black produced primarily from petroleum and is much more price-efficient to be used as raw materials in the industries listed.

Carbon black is used as raw material in many industries and the chemical structure of carbon black strengthens, lengthens the endurance and improves the coloring features of the materials.

3. STEEL WIRE (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after the P Valuable steel wires are pressed and sold to steel and scrap dealers.

4. GAS (5% to 8%)

Non-Condensable gases arise during the pyrolysis process.

Fuel oil appliaction

According to the 2010 Greendex report by the National Geographic Society and the international polling firm GlobeScan, Brazil is ranked the second regarding concern of sustainable consumption in the world, only trailing India. According to the official statistics, it shows that 250,000 unserviceable tires were collected in 2009. The waste tires can be transformed into asphalt, shoes, ducts, floors, carpets, and even alternative tire fuel oil. But when they’re not recycled, the tires are disposed into dump sites and cause great harm to the environment. Can you imagine that it takes up to 150 years to decompose the waste tire? It is definitely necessary to ensure that these tires end up being recycled andn disposed properly. Here I will introduce you a good way for waste tire management, the waste tire recycling to diesel, turn waste to energy and create profits, we have no reason to refuse it.

New way to disposal waste tires by waste tire to diesel machine

Why waste tire can be recycling to diesel fuel?

Tire components: A tire is made of natural rubber (also named as virgin rubber), Styrene-Butadiene(SBR), Polybutadiene Rubber(PBR), Carbon Black, Nylon tire cord, rubber chemicals, steel tire cord and Butyl rubber. The waste tire recycling to diesel process is the decomposition of tire polymer since waste tires are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross link or straight chain. During high temperature pyrolysis processing, the long chain( C-50000 to C-200000) in tire was broken down into smaller chains (C-1 to C-4 & C-5 to C-23). Among these elements, C5-C23 is oil polymer got from tire long chain polymer.

Waste tire disposal

Final products of waste tire recycling to diesel and usage:

1. FUEL OIL (45% to 50%)

The main product generated by our waste tire recycling to diesel plant is fuel oil which is widely used in industrial field so that has great commercial benefits. The oil has 45% to 50% yield of the amount of recycled scrap tyres, which can be used in power plant factory, glass factory, cement factory, ceramic factory, aluminum factory, boiler factory, central heating factory etc.

2. CARBON BLACK (30% to 35%)

Carbon black produced by waste tire recycling to diesel plant is more economical compared to carbon black produced primarily from petroleum and is much more price-efficient to be used as raw materials in the industries listed.

Carbon black is used as raw material in many industries and the chemical structure of carbon black strengthens, lengthens the endurance and improves the coloring features of the materials.

3. STEEL WIRE (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after the P Valuable steel wires are pressed and sold to steel and scrap dealers.

4. GAS (5% to 8%)

Non-Condensable gases arise during the pyrolysis process.

Fuel oil appliaction

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications