Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

Waste Tyre Pyrolysis Oil Appications and Processing Process

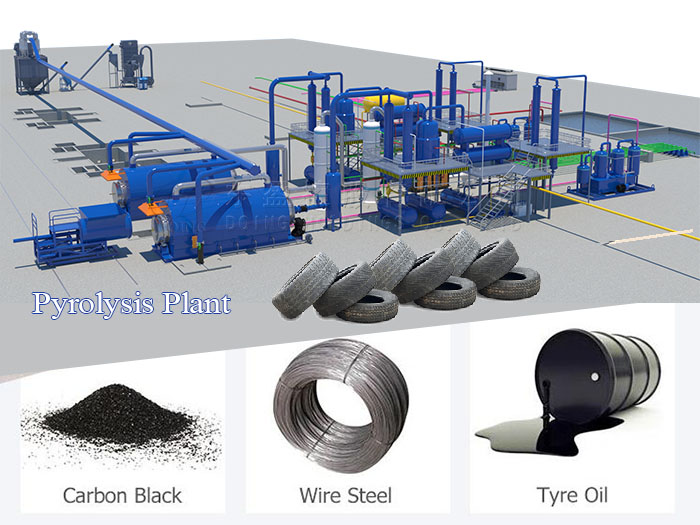

When you are using a pyrolysis oil plant to recycle waste tyres or waste rubber, you will get the valuable tyre pyrolysis oil and carbon black. Both of the end products are useful resources and can be applied in many industries. We will introduce the details on tyre pyrolysis oil on this page.

What is Tyre Pyrolysis Oil (TPO)?

Tyre pyrolysis oil, abbreviated as TPO, is the target product of waste tyre pyrolysis. It is a product obtained by condensing the oil gas decomposed by the high-temperature process. The oil is widely used as industrial fuel to substitute furnace oil or industrial diesel. It can also be called tire pyrolysis oil, crude TPO, tire pyrolytic oil, etc.

Waste tyres pyrolysis plant

Waste tyres pyrolysis plant

Tire Pyrolysis Oil Usage

In the waste tyre pyrolysis process, we can finally get waste tire pyrolysis oil and pyrolysis carbon black. Both of the final precious products can be sold directly at a high price in the market, or applied in many industries.

(1)Uses of tire pyrolysis oil

The tyre oil uses are wide. The waste tyre pyrolysis oil is mainly used as fuel in heavy industries such as cement plants, glass factories, ceramic factories, brick factories, heavy oil power plants, steel factories, and boiler factories and warm supply centers and so on. It can be also refined into diesel fuel by waste oil distillation unit, to be used in more areas or sold at a higher price.

(2)Uses of carbon black from tyre pyrolysis

The carbon black from tyre pyrolysis can be used as the raw material to produce fortifiers, filler and colorants in the rubber and plastic industry. It can be also refined into higher-quality carbon black like N330, N660, to earn a higher price in the market.

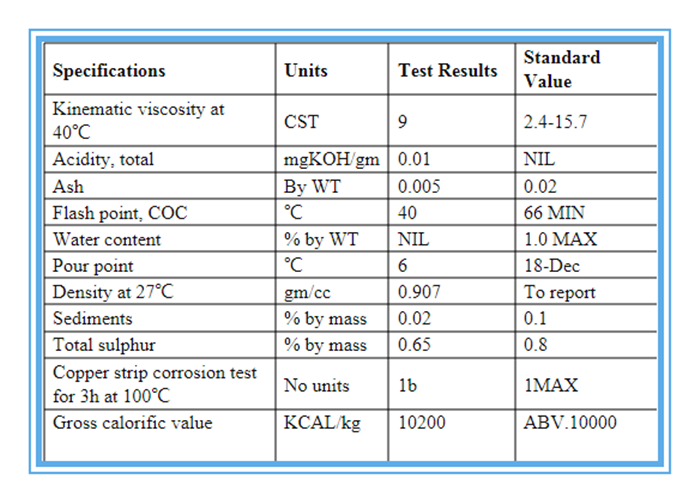

Tyre Pyrolysis Oil Specifications

Here is the test result of waste tyre oil. The tire pyrolysis oil specifications are listed below.

Note: the date is just a part of the result for your reference. You can have a look at the detailed PDF report on waste tyre oil here.

The detailed PDF report on waste tyre oil

The detailed PDF report on waste tyre oil

Yield of Scrap Tire Pyrolysis Oil

The oil yield of waste tyres and rubber is between 35%-50%, which means that you can get about 3.5-5ton pyrolysis fuel oil from 10ton waste tyres. The yield of waste tire pyrolysis oil depends on different types of tyres. For example, the oil yield of big car tires, truck tires and OTR tires is 45%-52%; the oil yield of small car tires, motorcycles, bicycle tires is 35%-40%; the oil yield of rubber cable sheath, rubber soles is about 35%; the oil yield of all kinds of rubber sheets or carpets is 30%; the oil yield of unclassified rubbers is about 35%.

Tyre Pyrolysis Oil Market Price

As the international oil price is continuously rising, the tire pyrolysis oil price could only go up. No matter in which country, the waste tyre pyrolysis oil price is stable and high. You never need to worry about the market and price of tire oil. If you want to learn about the detailed tyre oil price in your country or location, you can search on your browser.

How to Get Tire Pyrolysis Oil?/ How to Make Oil from Tyres?

The tyre pyrolysis oil production process from tyres is divided into 4 steps, including pyrolysis reaction, de-dusting, discharging, and wire extraction. By using the latest pyrolysis plant designed by Henan DOING Company, we can get the fuel oil from old tyres and rubber at a high efficiency. You can read about the detailed waste tyre pyrolysis process here.

Prospects of Extracting Pyrolysis Oil from Waste Tires

As more and more countries attach great importance to environmental issues, the management and disposal of waste tires has become extremely important. As an important and ideal way for the recycling of waste tires, the research on waste tire recycling has positive significance for promoting resource conservation and comprehensive utilization, transformation of economic growth mode and sustainable development. So buying a waste tyre pyrolysis plant is a profitable and meaningful business.

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.