Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

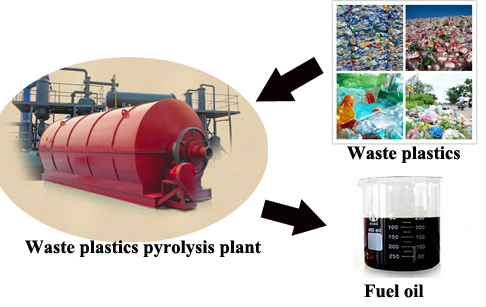

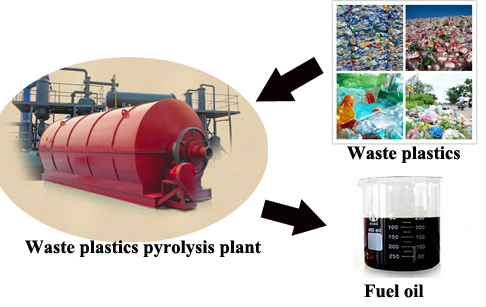

Plastic to fuel oil conversion machine

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine is to conver waste plastic into fuel.The raw material of plastic to fuel oil conversion machine is waste plastic , waste tyre ,waste rubber and so on .After pyrolysis of machine change plastic to oil ,we can get fuel oil ,carbon black and exhaust gas.

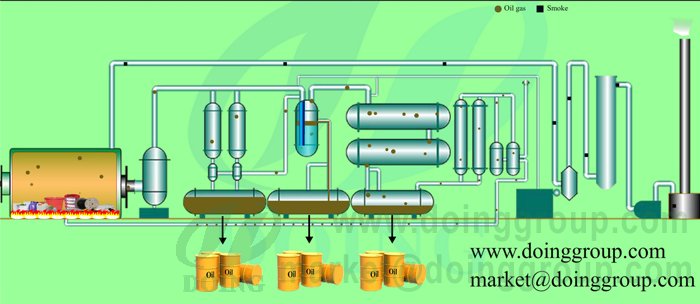

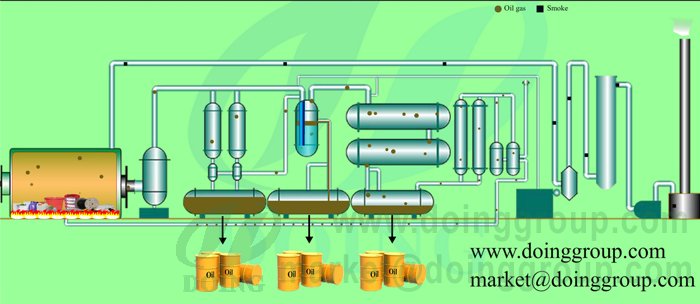

Plastic to fuel oil conversion machine working process

Plastic to fuel oil conversion machine

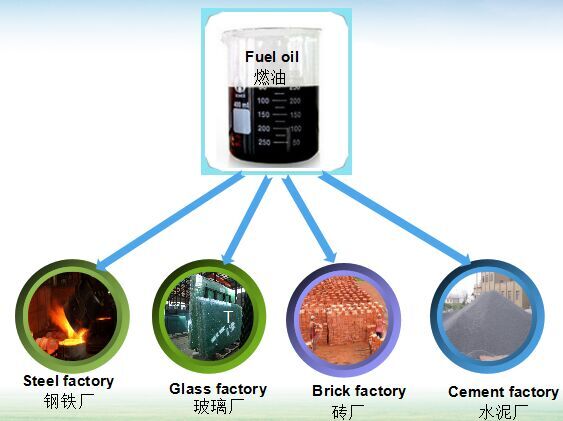

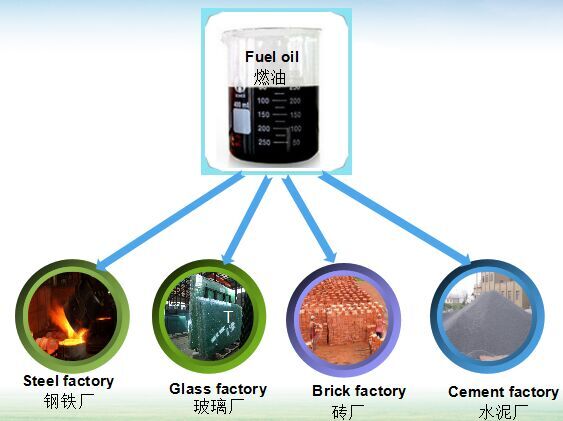

Fuel oil from plastic to fuel oil conversion machineused in below industries

Fuel oil application

A.Power plant factory

B.Glass factory

C.Cement factory

D.Ceramic fatory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

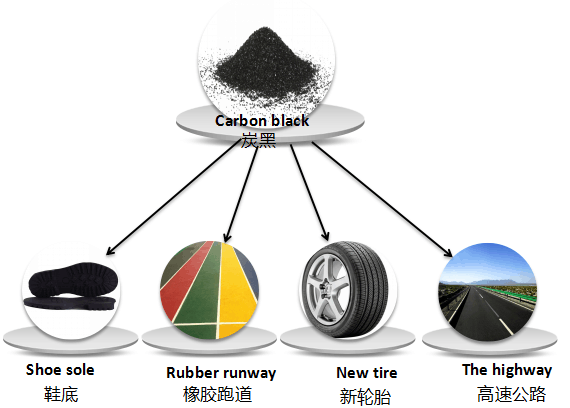

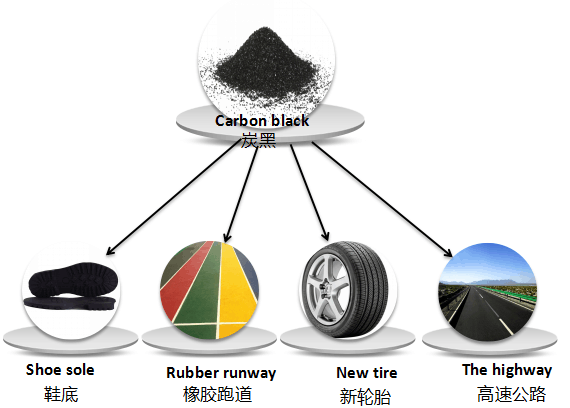

Carbon black application

Carbon black from plastic to fuel oil conversion machine

A.Electric cable jacketing

B.Conveyor ban

C.Hose and doormat

D.Black nylon bag

E.Rubber additive

F.Automatic spare parts

G.Heat isolation

H.Black colorant in rubber materials

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine working process

Plastic to fuel oil conversion machine

First, the raw materials are put into the reactor and seal the doors in the reacto

Second, start the machine and reactor will rotating and be heated. When the inside

temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

Third, in oil gas separator, light component will enter the condensers, meanwhile,

heavy component will be liquefied and then automatically discharged into heavy oil tank

Forth, most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning.After all these steps, you can start another batch.

Plastic to fuel oil conversion machine tech data

Second, start the machine and reactor will rotating and be heated. When the inside

temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

Third, in oil gas separator, light component will enter the condensers, meanwhile,

heavy component will be liquefied and then automatically discharged into heavy oil tank

Forth, most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning.After all these steps, you can start another batch.

Plastic to fuel oil conversion machine tech data

| Technical parameter of plastic to fuel oil conversion machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about plastic to fuel oil conversion machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Fuel oil from plastic to fuel oil conversion machineused in below industries

Fuel oil application

B.Glass factory

C.Cement factory

D.Ceramic fatory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

Carbon black application

A.Electric cable jacketing

B.Conveyor ban

C.Hose and doormat

D.Black nylon bag

E.Rubber additive

F.Automatic spare parts

G.Heat isolation

H.Black colorant in rubber materials

Request a Quote for the Plastic to fuel oil conversion machine

Please leave your contact information and Plastic to fuel oil conversion machine requirements so that our professional team can contact you as soon as possible.