Plastic recycling plant design

Henan Doing Mechanical Equipment Co.,Ltd is a leading manufacturer specialized in waste tire /plastic/rubber pyrolysis plant in China. Now, the design of DOING's waste plastic recycling plant is quite most advanced in all of Chinese market.

Plastic recycling plant design

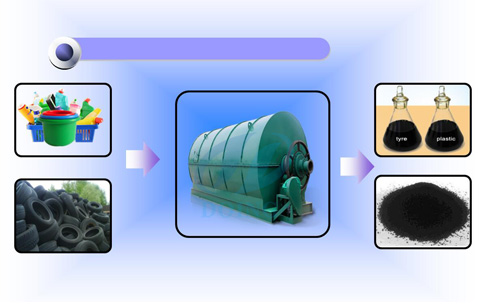

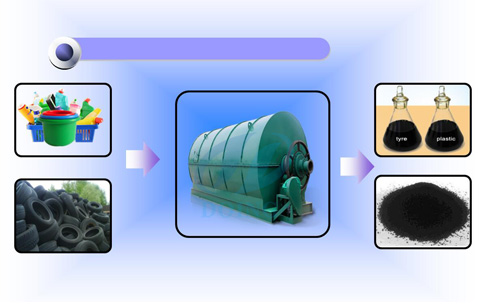

Waste plastic recycling plant adopts the advanced pyrolysis technology which can convert plastics to fuel oil and carbon black. These two kinds of pyrolysis products can be applied to different fields. For example, the fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. Both of the end-products are of a big commercial value.

Plastic recycling plant design

DOING new design of waste plastic recycling plant take professional pressure vessel design reactor with insulation covers. Secondly the whole system has professional safety devices including thermal gauge ,pressure gauge,safety valve,vacuum system,water seal and oil water separator. Thirdly, the whole system have professional dedust device to guarantee the emission from chimney is environmental friendly. Finally, our waste plastic recycling plant design have water circulation system,all of the water is recycled and it is very efficient and clean.

1. Pyrolysis plant Reactor

Plastic recycling plant Reactor

It is the most important part of the pyrolysis plant, because it is the place where pyrolysis process takes place. Our reactor is made from Q345R steel, which can avoid it being burnt through, thus the service life of the reactor is longer. In addition, the reactor of batch and semi-continuous plastic waste pyrolysis machine is rotary, but for the fully continuous pyrolysis plant, the reactor is fixed. So the heating efficiency and working efficiency can be increased basing on the different capacity.

2. Condenser

Plastic recycling plant condenser

The new-type tubular condenser has the features of larger cooling area and better cooling effect. So it can improve the oil yield efficiency.

3. Dedusting System

Plastic recycling plant dedusting System

It mainly includes water sprayer, ceramic ring filter and washing chamber. It can remove the dust, dioxin and other component in the combustible gas, then the gas can be recycled to heat the reactor. Thus you can save a lot of energy cost. For the exhaust gas produced by burning the fuel, it can also be purified by the de-dusting system before emission.

5. Safety device

Plastic recycling plant Safety device

The pyrolysis plant is equipped with advanced safety devices, such as over temperature and pressure alarm system, auto pressure releasing system, protecting shell, fire fighting devices and so on, all of which can ensure the plant can work in a safe condition. At the same time, it can also protect the workers.

6. PLC Controlling System

Plastic recycling plant PLC Controlling System

It can achieve intelligent operation and avoid the mistakes caused by manual operation.