Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

Tyre recycling machinery for sale

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Tyre recycling machinery

How to find a green and benefit way to process waste tyre?

To achieve a green way for processing the waste tyre, we developed the waste tyre recycling machinery for dealing with the waste tyre. This way not only can make disposal for the waste tyre, you also can get valuable products, like fuel oil, carbon black and steel wire for all kinds of commercial use. It' s a low investment but high benefit project.

Tyre recycling machinery working process

Tyre recycling machinery working process

1. The processed raw material is put into the pyrolysis reactor automatically. When the inner temperature of the pyrolysis reactor reaches related degree, the oil gas will be generated.

2. Then the oil gas goes into the manifold firstly. In the manifold, the heavy oil gas will be liquefied into heavy oil and drop in the heavy oil tank. The light oil gas rise up to the condenser, and then be liquefied into oil. In the hydroseal, the combustible gas will be desulfurated and cleaned then recycled to heat the pyrolysis reactor.

3. The smoke produced when heat the reactor will be cooled down, then enters the de-dusting system. In the spraying tower, the smoke will go through the water washing, water spray, and ceramic ring adsorption, so the smoke can meet the EU environmental protection and emission standards.

4. As for the carbon black, it will be discharged by the auto screw discharger.

Tyre recycling machinery final product application

Tyre recycling machine final product

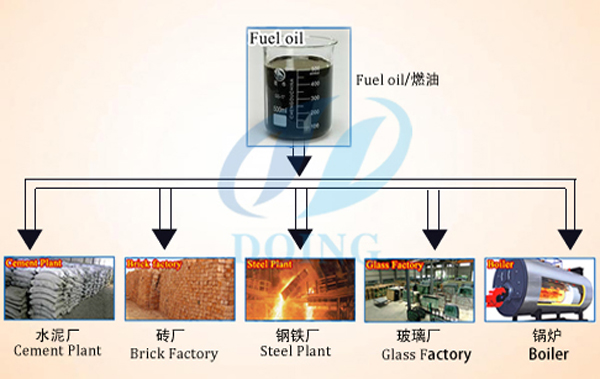

Fuel oil application:

Tyre fuel oil application

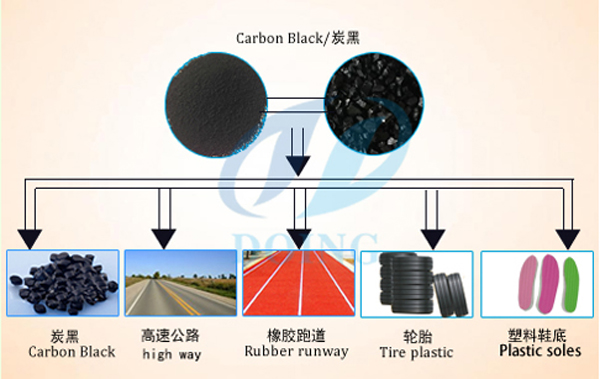

Carbon black Application:

Carbon black application

Carbon black produced from this waste tire recycling machinery is crude powdery material, which can be directly sold to cement factory mix with cement. Or made into briquettes used for heating, just like coal. Or grinded into fine powder used for making paint and printing ink.

Steel wire application:

Scrap steel wire can be directly sold to iron recycling station or steel mill for further treatment.

Tyre recycling have different way.

1. Made of rubber powder

2. Tire refurbishment

3. Crack into fuel oil, carbon black.

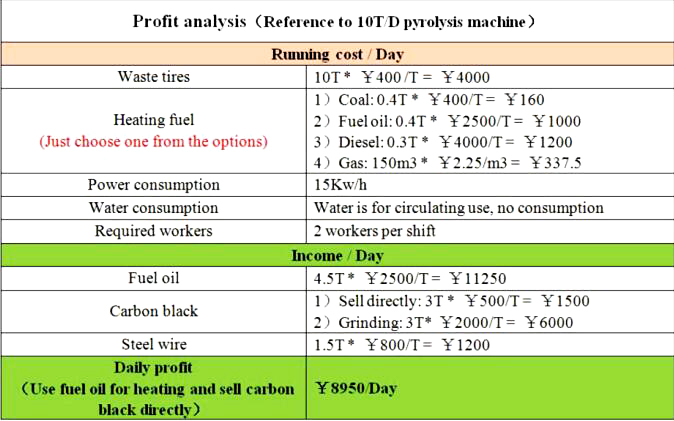

But the waste tire recycling by waste tire pyrolysis plant is the most popular way.And by this way ,the customer can earn huge profits.The detail profits analysis are as follows:

10T waste tire pyrolysis plant profits anlysis

Nowadays, the waste tire pyrolysis plant is very hot. There are many customers who consult the equipment in various ways every day. Most of the customers want to see our equipment. Now is the best time to invest in waste tire pyrolysis plant, and the sooner you invest, the sooner you will benefit !

Request a Quote for the Tyre recycling machinery for sale

Please leave your contact information and Tyre recycling machinery for sale requirements so that our professional team can contact you as soon as possible.