Product Center

Service Hotline:

+86-135-2669-2320- Contact: bonniezhao2

- Tel/WhatsApp: +86-135-2669-2320

- E-mail: sales@doinggroup.com

FAQ

- 04-13

How to recycle waste lubricating oil and turn waste into treasure?

- 02-16

Waste Tire Pyrolysis Machine---Three Types to Choose From

- 12-28

End-of-life Tires Derived Fuel For Industrial Plants Solutions

- 12-14

Pyrolysis Plant FAQ1---Raw material Selection and Processing

- 12-14

Pyrolysis Plant FAQ2---Final Product&Applications

- 12-02

What waste can be used for pyrolysis?

Rubber tyre pyrolysis plant

We provide free trial service.

You can also visit our factory.

- Tel: +86-135-2669-2320

- WhatsApp: 008613526692320

- Skype: bonniezhao2

- Phone: + 86-371-56771821

- Email: sales@doinggroup.com

Rubber tyre pyrolysis plant

Rubber tyre pyrolysis plant adopts pyrolysis technology that can pyrolysis waste rubber tyre to pyrolysis oil ,carbon black and carbon black and steel wire.

Rubber tyre pyrolysis plant

And hoe is the rubber tyre pyrolysis plant working processs ?The specific information are as follows:

Rubber tyre pyrolysis plant working process

1. Waste rubber tyre are feed into the pyrolysis reactor automatically. Before feeding, the wire drawing machine will draw the steel wires out of the waste tyres and then the tyre shredder will shred the tyres into pieces.

2. After the inner temperature of the reactor reaches to certain degree by heating, oil gas will be generated and then go to the manifold. Heavy oil will be liquefied into heavy oil and discharged in heavy oil tank. Light oil will rise into the tube condenser and then liquefied into oil.

3. Combustible gas generated during the process will be desulfurated and cleaned and finally reused as fuel to heat the reactor.

4. The smoke produced while heating will be cooled down and then enter into de-dusting system. After that, the smoke will go through the water washing, water spray, and ceramic ring adsorption to meet the EU environmental protection and emission standards. Meanwhile, the auto screw discharger discharge the carbon black out.

Through the rubber tyre pyrolysis plant working process,you can finally get 45-50% fuel oil,30% carbon black,15% steel wire,5% gas.They can be widely used in our dailylife.And bring you much profits!Tje specific application of the rubber tyre pyrolysis plant are as follows:

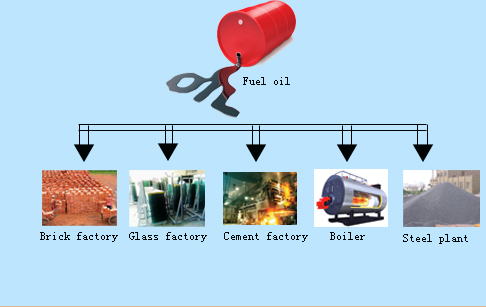

Fuel oil application

Carbon black application

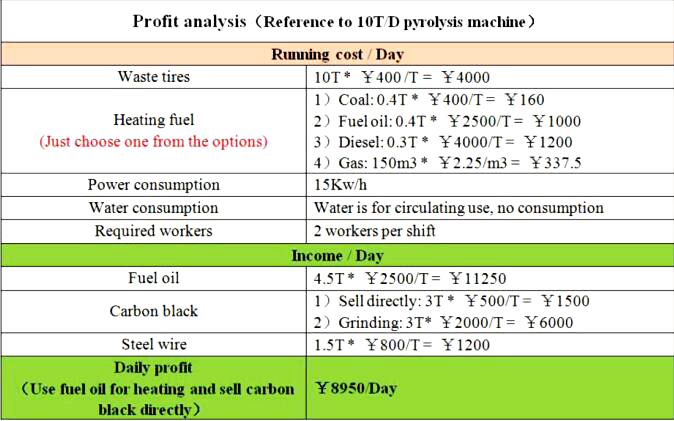

Many people know the finally products , especially the fuel oil after sold can earn profits.But they don't know the specicfic profits analysis , take 10T rubber tyre pyrolysis plant as example,the profits analysis are as follows:

10T rubber tyre pyrolysis plant profits analysis

The profits is not empty, we have a customer marked with red line in the photo are our old customer Mr Victor and Mr Gauden from Macedonia. This customer bought 3 sets rubber tyre pyrolysis plant from our company.

Macedonia customer pictures

In the last several years, they came to China 3times for our DOING rubber tyre pyrolysis machine. Their first visit was in July 2011 when they started the tyre recycling to oil business by giving the 1st trial order to us. With the annual profit around USD1,000,100.00, they made a visit to us in December 2012 and October 2014 for the second and third order.

Are you also interested in our rubber tyre pyrolysis plant ?feel free to cousulting more detail information about thr rubber tyre pyrolysis plant at your time!!

Are you also interested in our rubber tyre pyrolysis plant ?feel free to cousulting more detail information about thr rubber tyre pyrolysis plant at your time!!

Request a Quote for the Rubber tyre pyrolysis plant

Please leave your contact information and Rubber tyre pyrolysis plant requirements so that our professional team can contact you as soon as possible.