Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

FAQ

Fully continuous tyre recycling pyrolysis plant

1. Fully automatic and controlled by PLC system;

2. Discharge continuously, greatly reduces the cost of time and labors;

3. Fully pyrolysis of tyres, improve the oil production rate.

We provide free trial service.

You can also visit our factory.

- Tel: +86-13526692320

- WhatsApp: +86-13526692320

- Phone: +86-37156771821

- Email: sales@doinggroup.com

In order to meet the higher requirements of more customers for pyrolysis plant, we developed and manufactured fully continuous tyre recycling pyrolysis plant, which has higher handling capacity and higher environmental protection.

Fully continuous tyre recycling pyrolysis plant

Fully continuous tyre recycling pyrolysis plant

The main working process of fully continuous tyre recycling pyrolysis plant

1. Pre-treatment

The steel wire in the waste tyres need to be drew out through the steel wire drawing machine. Then crush the whole tyres into small pieces by the tyre crusher.

2. Feeding tyres

Feed the tyres into the reactor of the fully continuous tyre recycling pyrolysis plant by a sealed screw pusher, which is safe and environmental.

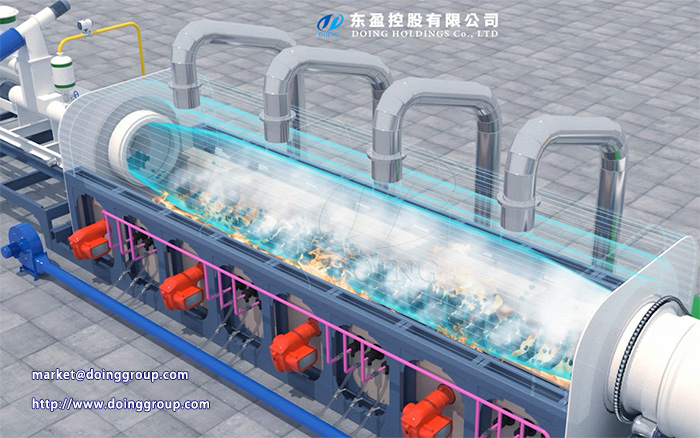

3. Pyrolysis

Through the control of PLC system, the pyrolysis reactor can be heated accurately. When reach a certain temperature, waste tyres will be pyrolyzed into oil gas.

Pyrolysis reactor is being heated

Pyrolysis reactor is being heated

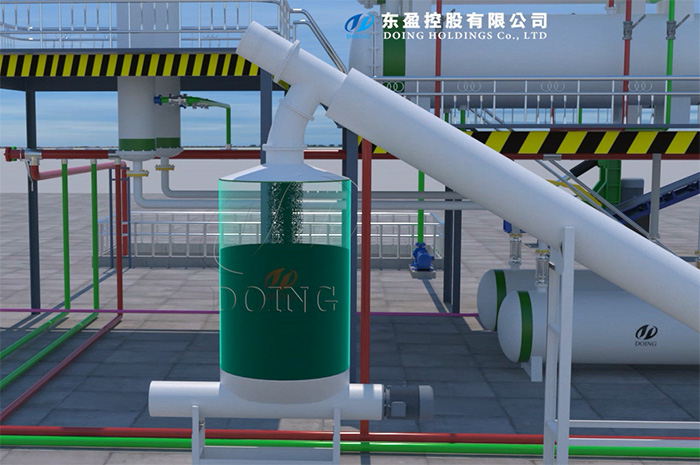

4. Cooling

The oil gas goes through horizontal and vertical condensers, and can be cooled into liquid oil which will be collected into the oil tanks.

5. Discharge

The obtained carbon black in the pyrolysis reactor can be discharged automatically through a sealed screw conveyor. It’s very convenient and no dust pollution.

Carbon black discharge

Carbon black discharge

Unique advantages of fully continuous tyre recycling pyrolysis plant

1. Fully continuous tyre recycling pyrolysis plant is a new type waste tyre recycling to fuel oil plant, which is fully automatic and controlled by PLC system;

2. The benefit is that it can feed tyres and discharge residues (carbon black and steel wire) continuously without a stop, which greatly reduces the cost of time and labors;

3. What’s more, its accurate calculated pyrolysis system can make sure fully pyrolysis of the tyres, which can not only improve the oil production rate, but also reduce waste and pollution.

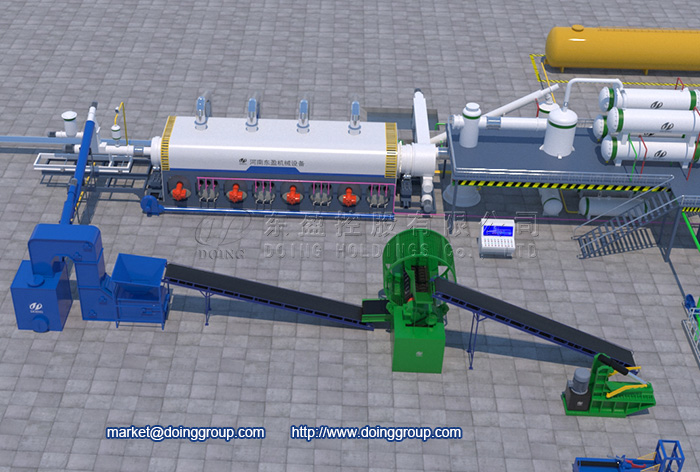

Full set fully continuous tyre recycling pyrolysis plant

Full set fully continuous tyre recycling pyrolysis plant

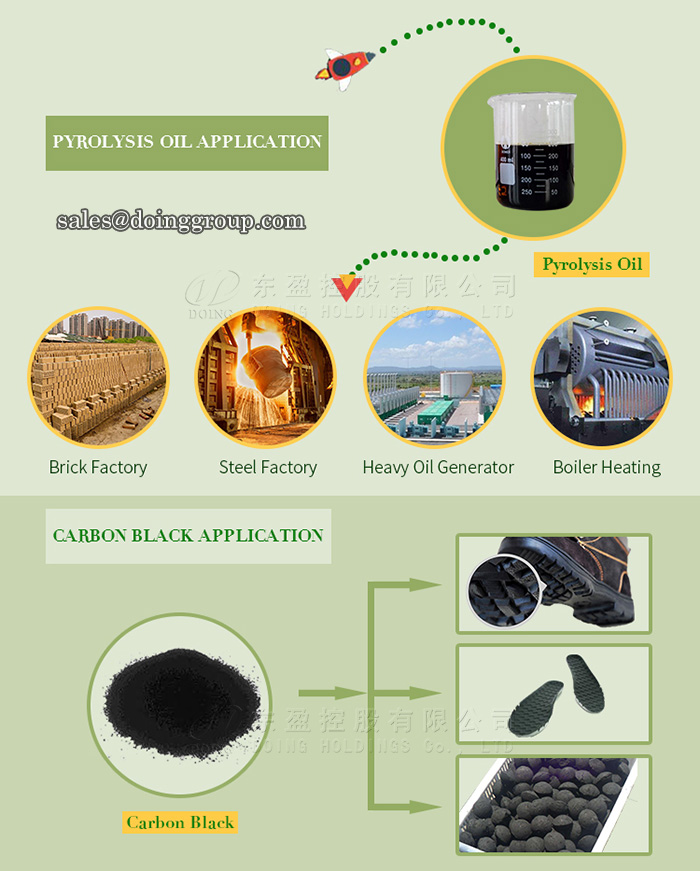

Final products of fully continuous tyre recycling pyrolysis plant

The main output of fully continuous tyre recycling pyrolysis plant are fuel oil, carbon black and steel wire. Both of them have many uses, good market and easy to be sold.

Fuel oil and carbon black uses

Fuel oil and carbon black uses

Now fully continuous tyre recycling pyrolysis plant has been recognized and advocated by many governments. If you are also shopping for fully continuous tyre recycling pyrolysis plant, please contact us directly and our professional project manager will give you more detailed introduction and free quotation.

Request a Quote for the Fully continuous tyre recycling pyrolysis plant

Please leave your contact information and Fully continuous tyre recycling pyrolysis plant requirements so that our professional team can contact you as soon as possible.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications